Polymer nanocomposites, a remarkable class of advanced materials, are revolutionizing multiple industries through their unique ability to amplify the properties of polymers by incorporating nanoscale fillers. Among these fillers, boron nitride (BN) stands out due to its exceptional thermal conductivity, dielectric prowess, and chemical stability.

Image Credit: Igor Petrushenko/Shutterstock.com

Introduction: Boron Nitride in Polymer Nanocomposites

Polymer nanocomposites are advanced materials with a polymer matrix reinforced with nanoscale fillers or additives. These fillers, typically nanoparticles, have at least one dimension less than 100 nanometers. The incorporation of nanoparticles into polymers enhances their properties and performance.

By dispersing nanofillers within the polymer matrix, nanocomposites can exhibit improved mechanical, thermal, electrical, and barrier properties compared to pure polymers. This technology has wide-ranging applications in aerospace, automotive, electronics, packaging, and more industries.1

Boron nitride (BN) is a remarkable nanomaterial that has gained considerable attention in polymer nanocomposites due to its exceptional thermal conductivity, dielectric properties, mechanical strength, and chemical and thermal stability. Its versatility makes it a valuable component for enhancing the performance of polymers in various industries and applications.1

The article aims to investigate and explain the key factors and benefits that make boron nitride a widely used and valuable nanomaterial in polymer nanocomposites. It seeks to explore how boron nitride enhances the properties of polymers, including thermal conductivity, electrical insulation, mechanical strength, barrier properties, and more. Additionally, the article delves into the industrial applications where these improved properties are crucial, demonstrating the versatile role of boron nitride in enhancing polymer performance in various sectors.

Boron Nitride’s Unique Properties

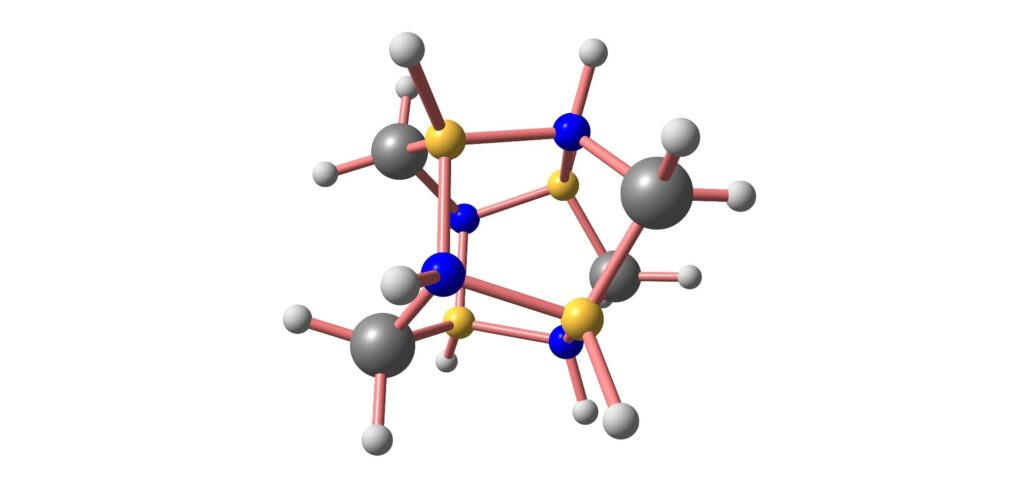

Boron nitride (BN) is highly regarded for its exceptional thermal conductivity, a rare feature among non-metallic materials. This arises from its crystal structure, resembling graphite in carbon, with hexagonal layers of boron and nitrogen atoms held by covalent solid bonds within layers and weak van der Waals forces between them. This unique structure allows efficient heat conduction along BN crystal planes, matching or surpassing metals like copper.

BN is thus a sought-after nanomaterial for enhancing heat dissipation in polymer nanocomposites. Furthermore, BN’s electrical insulation properties, including high dielectric strength, low dielectric loss, and high breakdown voltage, make it invaluable in electrical applications, preventing electrical discharge in high-voltage settings.2

BN offers exceptional thermal stability and chemical inertness, withstanding high temperatures and harsh chemical environments without significant degradation. It remains structurally intact even at elevated temperatures.2

BN’s lubricious nature, akin to graphite, reduces friction and wear when added to polymers, enhancing tribological performance, extending component lifespan, and reducing heat generation in applications like bearings and seals.2

Enhancing Thermal and Electrical Properties in Polymers

Adding BN nanoparticles into polymers greatly enhances thermal conductivity through several mechanisms. Firstly, BN provides additional heat transfer pathways within the polymer matrix, thanks to its efficient heat-conducting hexagonal layers. Second, uniform dispersion of BN particles is critical, as well-dispersed nanoparticles form a conductive network, facilitating heat transfer. Lastly, BN’s high aspect ratio means that even a tiny quantity can cover a large surface area, further boosting thermal conductivity.3

BN also plays a crucial role in enhancing electrical insulation properties in polymer nanocomposites. It achieves this through multiple means: boron nitride nanoparticles possess high dielectric strength, insulating effectively against high voltages, ensuring the safe operation of electrical components. Their low dielectric loss minimizes energy loss, as heat is crucial for energy-efficient systems.3

These versatile BN-polymer nanocomposites find applications across industries, enhancing electronic heat dissipation, providing thermal management and electrical insulation in aerospace, maintaining electrical integrity in high-voltage equipment, and contributing to weight reduction and improved performance in automotive parts.

Tailoring Mechanical Strength and Barrier Properties

Boron nitride nanoparticles in polymers significantly enhance mechanical properties, including strength and stiffness, owing to its high Young’s modulus. When dispersed in a polymer matrix, these nanoparticles act as effective reinforcing agents, increasing the composite’s stiffness and load-bearing capacity. This reduces deformation or failure under stress, making BN-polymer nanocomposites valuable for applications requiring enhanced mechanical strength and rigidity.1

BN also plays a crucial role in improving barrier properties by hindering the permeation of gases and liquids. BN nanoparticles create a convoluted path in the case of gases, slowing gas diffusion within the polymer matrix, particularly for oxygen and moisture, enhancing gas barrier properties.1

These versatile materials find applications in the automotive industry, enhancing the mechanical properties of components like engine covers and brake parts and improving vehicle performance and durability. Food packaging enhances barrier properties, preserving freshness and quality by safeguarding against gases, moisture, and contaminants. Moreover, their use in critical equipment benefits the oil and gas sector by providing superior mechanical strength and chemical resistance, leading to extended service life and reduced maintenance costs.

Image Credit: chemical industry/Shutterstock.com

Dispersion and Compatibility Challenges

Achieving uniform dispersion of BN nanoparticles within polymer matrices is essential for optimizing BN’s reinforcement effects. However, challenges often hinder this goal. BN particles tend to agglomerate due to van der Waals forces, reducing the available surface area for reinforcement and leading to uneven property improvements. Addressing these challenges is crucial for harnessing the full potential of BN-polymer nanocomposites in various applications.4

Several strategies can be employed to overcome dispersion and compatibility issues when incorporating BN nanoparticles into polymer matrices. These include surface functionalization techniques like silane treatment, plasma treatment, or the use of surfactants to enhance BN’s adhesion to the polymer and reduce agglomeration.

Proper solvent selection, favoring polar solvents that interact effectively with BN’s surface, can improve dispersion. Techniques like sonication and high-shear mixing break down agglomerates, while pre-dispersion methods such as ball milling ensure uniform distribution.5

Current and Emerging Applications of Boron Nitride-Polymer Nanocomposites

Boron nitride-polymer nanocomposites find extensive industrial applications due to their unique properties. They serve as thermal interface materials (TIMs) in electronics, flame-retardant coatings in textiles and construction materials, and electrical insulation materials for high-voltage equipment.

These composites are also utilized in aerospace components, automotive parts, and oil and gas equipment, enhancing mechanical properties, thermal stability, and resistance to harsh conditions. Additionally, they improve gas and moisture barrier properties in food packaging, preserving the freshness of packaged products.1,6

Ongoing research focuses on optimizing the integration of BN into polymer matrices. This includes advanced dispersion techniques for uniform dispersion and improved adhesion, the development of nanostructured BN-polymer composites for precise control over nanoparticle characteristics, and exploring synergistic combinations with other nanomaterials like carbon nanotubes or graphene for superior properties. As materials science advances, BN-polymer nanocomposites are expected to find new applications in various industries, driven by efforts to enhance their dispersion, compatibility, and performance.6

In conclusion, BN plays a versatile and crucial role in enhancing the properties of polymer nanocomposites, making them invaluable in a wide range of industrial applications. Its ability to improve thermal conductivity, electrical insulation, mechanical strength, and barrier properties while reducing friction highlights its multifaceted benefits in the world of advanced materials.

See More: Transforming Composite Materials with Boron Nitride NanoBarbs

References and Further Reading

Rasul, M. G., et al. (2021) 2D boron nitride nanosheets for polymer composite materials. npj 2D Materials and Applications, 5, p. 56.

Aparna, A., et al. (2021) Recent Advances in Boron Nitride Based Hybrid Polymer Nanocomposites. Macromolecular Materials and Engineering, 306, p. 2100429.

Joy, J., et al. (2020) An overview of boron nitride based polymer nanocomposites. Journal of Polymer Science, 58, pp. 3115–3141.

Jordan, J., et al. (2005) Experimental trends in polymer nanocomposites—a review. Materials Science and Engineering: A, 393, pp. 1–11.

Lin, Y. et al. (2011) Aqueous dispersions of few-layered and monolayered hexagonal boron nitride nanosheets from sonication-assisted hydrolysis: critical role of water. The Journal of Physical Chemistry C, 115, pp. 2679–2685.

Dean, C. R. et al. (2010) Boron nitride substrates for high-quality graphene electronics. Nature Nanotechnology, 5, pp. 722–726.