Many materials have been explored for 3D printing, but most lack favorable chemical, mechanical, electrical, and biological properties. Multiple studies have revealed that graphene or graphene-based materials possess unique properties, making them ideal for 3D printing.1

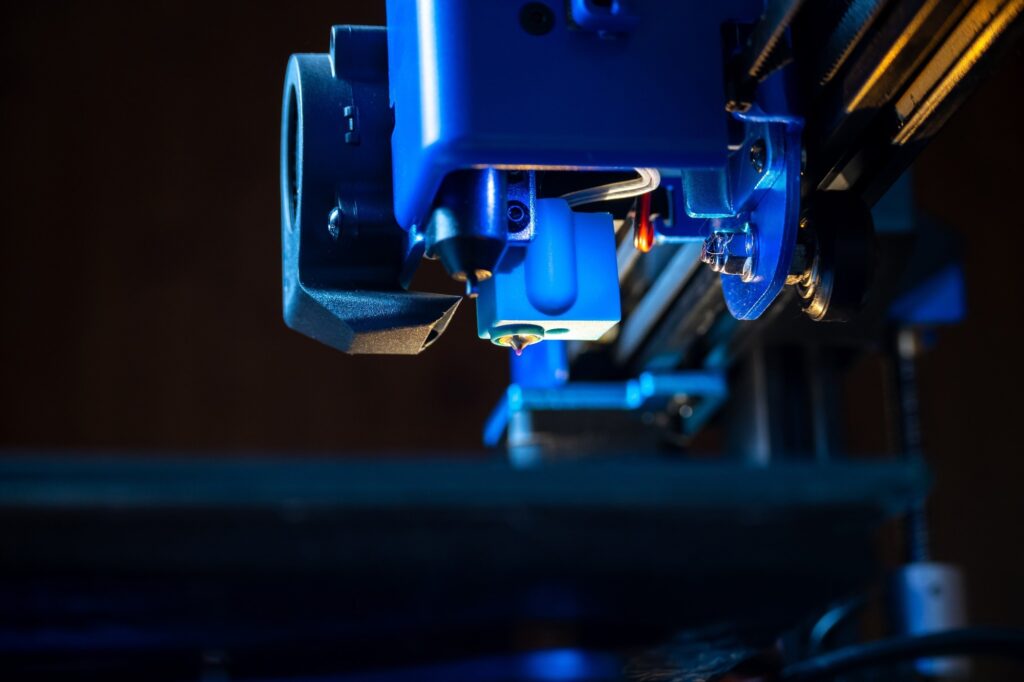

Image Credit: G. Soler Tomasella/Shutterstock.com

What is 3D Printing?

3D printing, also known as additive manufacturing or digital fabrication technology, creates physical objects through precise layer-by-layer deposition of material directly from a computer-aided design (CAD) model.2

Some technologies used in 3D printing include Selective Laser Sintering (SLS), binder jet powder bed 3D printing, Fused Deposition Modeling (FDM), Stereolithography (SLA), PolyJet, inkjet 3D printing, and Direct Metal Laser Sintering (DMLS).3

3D Bioprinting

3D bioprinting is a novel technique that enables the development of new implants and transplants for organ restoration and regeneration.4 Conventional methods for 3D tissue-engineered scaffolds are solvent casting, salt leaching, and freeze-drying.

Recent advancements in 3D bioprinting have allowed engineers to construct implants and tissue scaffolds quickly and cost-effectively.

Raw Materials for 3D Printing

To build high-quality devices using 3D printing technology, it is essential to provide raw materials with consistent specifications. Various materials, including natural, synthetic, ceramic, metallic, and their composite or hybrid forms, have been explored and developed for 3D printing.

Each material exhibits advantages and limitations; for example, natural polymers have ideal biocompatibility but lack electrical and mechanical properties, while ceramic materials are prone to cracking due to brittleness.

What are the Properties of Graphene?

Nanomaterials, particularly carbon nanotubes and graphene, have unique stability, strength, and bioactivity, making them ideal for 3D-printed constructs.1 Graphene and graphene-based derivatives, such as graphene oxide (GO), reduced GO (rGO), and functional GO (fGO), have been used as nanofillers in polymer-based scaffolds. These materials enhance the thermal, mechanical, chemical, and electrical properties of the scaffolds.

Graphene is composed of two-dimensional (2D) hexagonal layers of carbon atoms forming single-, bi-, and multi-layer structures with distinct geometries. Its surface is chemically inert, but its edges are active and can interact with various chemical groups such as carbonyl, hydrogenated, carboxyl, and amines.4

3D Printing Techniques

Various techniques are used to develop 3D graphene scaffolds or prints, including FDM, SLS, and SLA. For example, the FDM technique was used to develop a 3D graphene scaffold with polyvinyl alcohol (PVA) and polylactic acid (PLA), while the SLA method was used for printing 0.1 wt% graphene, GO, and graphite nanoplatelets (GOxNP) amended with photopolymerizable acrylic resin.5

Each technique has advantages and limitations; for instance, graphene scaffolds developed by SLA exhibited poor biocompatibility and degradability.6

Although SLS is a fast and precise 3D printing method, it requires high melting temperatures. Engineers developed a 3D-printed graphene/polyether ether ketone scaffold using the SLS method, which exhibited prominent mechanical strength, flexibility, and enhanced electrical conductivity.

GO is commonly used for tissue engineering applications due to its high mechanical strength, hydrophilic functionalities, and biodegradability, which reduce the risk of long-term inflammation. GO, integrated with polymers, solvents, and additives, is also used as ink for 3D printing applications.

rGO offers suitable biocompatibility with many cell types, making it a promising material for tissue engineering applications. Typically, the FDM method is used to develop rGO scaffolds.

Applications of 3D Printed Graphene

3D-printed graphene is applied in many fields of science and technology, including medicine and electronics.

Tissue Engineering

In tissue engineering, 3D-printed graphene-based scaffolds are used to develop hard and soft tissues.1 For hard tissue engineering, these printed materials possess biological and mechanical properties that promote bone differentiation and resorption upon tissue regeneration. Engineers have demonstrated the osteogenic potential of periodontal ligament stem cells cultured on 3D graphene substrates.7

Previous studies have also shown the effectiveness of 3D-printed graphene-based scaffolds for treating osteosarcoma. 3D-printed chitosan/GO scaffolds have been used to treat critical-size calvarial bone defects. Synthetic polymers are often combined with graphene-based materials to develop 3D-printed bone scaffolds with high compressive strength, cytocompatibility, modulus, and bioactivity for osteogenesis.1

3D graphene prints are also used for soft tissue engineering, particularly neural and cardiac regeneration. Together with growth factors and anticoagulants, graphene promotes nerve cell growth and differentiation.8 It also enhances adhesion and the bioelectricity of human neuronal stem cells (hNSCs).

The newly developed 3D graphene mesh tube filled with alginate and GelMA double network hydrogel offers suitable conductivity and mechanical strength for supporting the proliferation and arrangement of nerve cells.

For cardiac scaffolds, graphene has offered enhanced electroconductivity, mechanical properties, and improved anisotropic nano topology. Cardiac implants developed with GO–gold nanosheet with chitosan scaffold offered improved ventricular contractility. A combination of rGO and alginate has also shown enhanced biocompatibility for cardiac repair.

Energy Storage and Electronics

Graphene and its derivatives are commonly used in energy storage due to their exceptional electrical conductivity, specific surface area, chemical stability, and high mechanical strength.9 3D-printed graphene is used in energy storage devices such as batteries and supercapacitors.10

Supercapacitors are important energy storage devices due to their high power density, long life for charging/discharging, and low cost. The performance of supercapacitors depends on the properties of the electrolyte and electrode materials. Binder-free GO-based inks have been used to print fGO-based electrodes that exhibit high charge/discharge capability and energy density.

Batteries are widely used for energy storage and conversion due to their high energy density, wide operating temperature, and low self-discharge. Graphene’s chemical properties make it an ideal electrode material.

3D printing techniques are used to fabricate 3D electrodes, which offer controlled shape, size, pore structure, and thickness. These electrodes have higher areal loading, low tortuosity, and fast ion-diffusion rates. 3D lithium-ion battery electrodes were developed using GO composite links.

In electronics, 3D printing is used for high accuracy, rapid prototyping, and simplicity. Graphene-based sensors have exceptional electrical properties and exhibit high sensitivity. To develop deformation-sensitive resistances for strain sensing, GO inks have been used on polyurethane (PU) substrates. The 3D graphene-printed e-skin is applied in robotics and microsensor applications.

The Future of 3D Printed Graphene

The future of 3D-printed graphene promises advancements in tissue engineering, energy storage, and electronics through enhanced material properties and printing techniques. Continued research will improve biocompatibility and biodegradability for medical applications.

Overall, the synergy between graphene’s unique properties and evolving 3D printing technologies will drive significant innovation across various fields.

More from AZoNano: Graphene Membranes: Applications in Modern Water Purification

References and Further Reading

- Patil, R., Alimperti, S. (2024). Graphene in 3D Bioprinting. J Funct Biomater. doi:10.3390/jfb15040082

- Shahrubudin, N., et al. (2019). An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manufacturing. doi:10.1016/j.promfg.2019.06.089

- Zhou, L., et al. (2024). Additive Manufacturing: A Comprehensive Review. Sensors (Basel). doi:10.3390/s24092668

- Cui, H., Nowicki, M., Fisher, JP., Zhang, LG. (2017). 3D Bioprinting for Organ Regeneration. Adv Healthc Mater. doi:10.1002/adhm.201601118

- Derakhshi, M., Daemi, S., Shahini, P., Habibzadeh, A., Mostafavi, E., Ashkarran, AA. (2017). Two-Dimensional Nanomaterials beyond Graphene for Biomedical Applications. J Funct Biomater. doi:10.3390/jfb13010027

- Gasparotto, M., et al. (2022). 3D Printed Graphene-PLA Scaffolds Promote Cell Alignment and Differentiation. Int J Mol Sci. doi:10.3390/ijms23031736

- Guo, J., Cao, G., Wei, S., Han, Y., Xu, P. (2023). Progress in the application of graphene and its derivatives to osteogenesis. Heliyon. doi:10.1016/j.heliyon.2023.e21872

- Geetha Bai, R., Muthoosamy, K., Manickam, S., Hilal-Alnaqbi, A. (1019). Graphene-based 3D scaffolds in tissue engineering: fabrication, applications, and future scope in liver tissue engineering. Int J Nanomedicine. doi:10.2147/IJN.S192779

- Sahoo, PK., et al. (2024). Recent progress in graphene and its derived hybrid materials for high-performance supercapacitor electrode applications. RSC Adv. doi:10.1039/d3ra06904d

- Jiang, Y., et al. (2021). Three-dimensional printing of graphene-based materials for energy storage and conversion. SusMat. doi:10.1002/sus2.27