Nanoimprint lithography (NIL) is a rapid, high-resolution nanopatterning method that meets industrial requirements with its high throughput and low cost. Its capability for easy, large-area production of nanoscale structures makes it suitable for various applications, including nanotechnology, microsystems, electronics, optical devices, and healthcare.

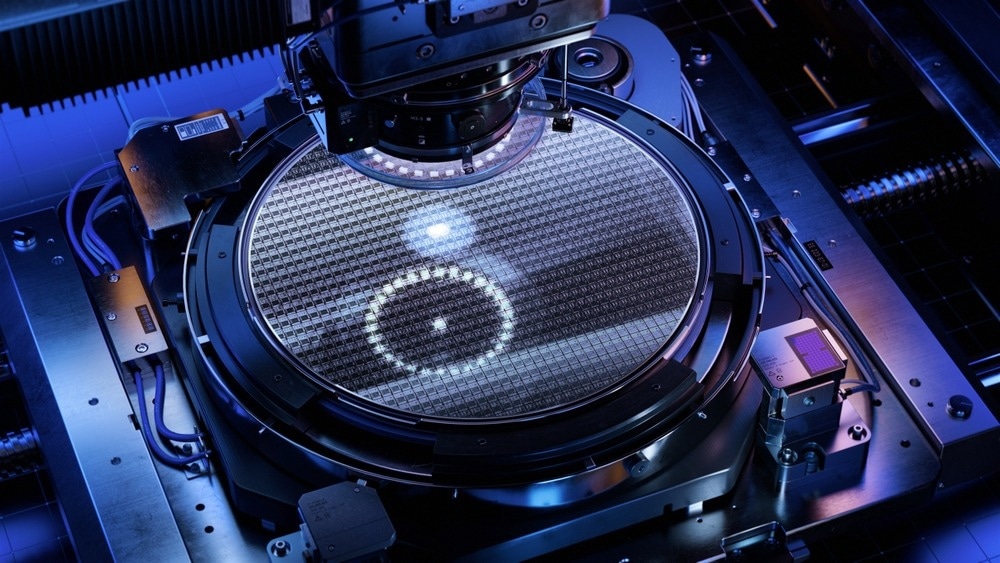

Image Credit: IM Imagery/Shutterstock.com

Further technological advancements are expanding the potential application of NIL to areas such as food safety and security, magnetic storage media, defense and law enforcement, and environmental monitoring.1 This article explores various applications of NIL and the related emerging trends

Principles and Operation of NIL

NIL involves spin-coating a polymer resist on a substrate and pressing a mold/stamp over it, causing the resist to fill the mold. The resin is then cured, and the mold is separated from the substrate to reveal the mold’s pattern replicated on the resist.

The surface chemistry of the mold and resist plays a crucial role in accurately transferring the pattern. Thus, several hard (silicon-based) and soft (polydimethylsiloxane (PDMS)) molds are used, depending on the target application.1

Various NIL methods have been developed using different resins and curing methods. For example, hot-embossing NIL uses a thermoplastic polymer, which is heated over its glass transition temperature and then cooled for curing. This method is preferred for its simplicity and capability to pattern many polymers. Alternatively, ultraviolet (UV) NIL uses UV-curable photopolymer resins and is suitable for high-aspect features.1

Nanostructure Patterning for Nanotechnology and Microsystems

NIL has established its ability to create almost sub-nm range features precisely and accurately. It is effectively used for nanostructure patterning various materials for nano- and microsystems. For instance, it has been recently used to produce flexible graphene micro-supercapacitors, nanoribbons, biomaterials, and other functional materials.2

The adaptability of NIL to continuous roll-to-roll nanomanufacturing enables its use in the economical production of high-performance flexible electronics and displays, biomedical devices, smart wearables, and energy devices.2 For example, nanostructured electrolyte membranes for fuel cells, fabricated using NIL, double the power generation density of the cell compared to conventional plane membranes.3

NIL has been used in nanopatterning various optical tools like fiber couplings, micro-scanning systems, micro-lenses, light guide plates, and spectrometers.2

Portable miniature spectrometers have recently gained significant attention in detecting food adulterations. However, these require micro(opto-)electro-mechanicals (M(O)Ems), particularly micromirrors and linear variable filters (LVFs), which, when produced using NIL, can significantly accelerate the production of miniature spectrometers.1

Applications in Electronics, Photonics, and Biomedical Devices

Current electronic systems, dominated by conventional integrated circuits (ICs) produced by photolithography, are being challenged by NIL, which can manufacture reliable electronic devices with better feature size and variation control.2 The fabrication of future electronic devices, such as memristors (a fourth-class passive device) with a metal/insulator/metal structure, can also be accomplished using NIL.2

As NIL-based fabrication covers the visible wavelength range, it is employed to manufacture various optical components and devices, such as polarizers, anti-reflectors, and micro-lenses. Displays with high resolution, thin panels, and low power consumption can also be manufactured on a large scale using NIL.

In addition to optical component fabrication, NIL enhances the performance of existing devices, such as solar cells, by controlling the light path.3

NIL also finds applications in various bio-processes and devices. It can be used to create structures for effective control of micron-sized stretched deoxyribonucleic acids (DNAs) and cells. NIL allows the preparation of 3D cell-culturing plates with distinct structures, which is essential for tissue culture in regenerative medicine.1,3

Fabrication of immunoassay chips and microfluidic chips, used in biosensors or as drug delivery vehicles in the human body, are other significant medical applications of this technique.1-3

Recent Advances and Industrial Applications

With improvements in throughput, alignment, defectivity, and mask replication, NIL methods are being applied in novel industrial applications. For instance, a recent article in Nanomanufacturing reviewed the use of NIL to produce biomimetic nanostructures, which find diverse applications in optics to life sciences.

Biomimetics uses natural solutions to solve challenges in engineering sciences. NIL enables the fabrication of biomimetics with complex structures for application in real-life environments. For example, multiple moth-eye antireflecting coatings have been nanostructured by NIL for smart television displays.4

Another recent article published in ACS Applied Nanomaterials proposed NIL to realize nanoscale back-contact perovskite solar cells with better performance than conventional ones, eliminating the need for transparent conductors.

Back-contact perovskite solar cells require electrodes with a width lower than 1000 nm, which cannot be achieved using current lift-off-based fabrication. To this end, a simple NIL-based etch-down procedure has been proposed for scalable production of honeycomb-shaped, quasi-interdigitated electrode structures with widths as small as 230 nm.5

Future Directions and Emerging Trends

Micro- and nanostructure fabrication using NIL can support several new technologies.2

For example, emerging drone technology is being rapidly adopted for several remote applications, yet the availability of replacement parts remains a significant bottleneck. NIL can produce high-resolution and cheaper components, thereby accelerating the adoption of drones.1

In the context of artificial intelligence and machine learning, the introduction of big data has increased the necessity for high-density storage media with smaller bit grain sizes to enhance storage capacity. NIL-based substrate patterning and annealing processes can control the feature size and morphology of the increasingly small bits, thereby aiding in the rapid advancement of intelligent systems.1

Technological advances also enhance the ability to manufacture counterfeit products. Thus, proactive methods are required to prevent product replication, for which quick-response (QR) codes concealed inside the product are widely used to identify genuine products.

Three-dimensional QR codes developed using NIL can feature pillars of varying pitches, generate areas of different reflectivity, and improve product identification, traceability, and security.1

The future concepts of nano-factories or factories-in-a-box can be actualized through nanopatterning via NIL. A nano-factory is a place or environment where molecular-level controlled nanomanufacturing occurs. NIL can act as a programmable mechanochemical fabricator for nanomanufacturing in such environments.2 Overall, NIL has the potential to revolutionize many future technologies.

More from AZoNano: Who Discovered Nanoparticles?

References and Further Reading

1. Stokes, K., Clark, K., Odetade, D., Hardy, M., Oppenheimer, P. G. (2023). Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications. Discover Nano. doi.org/10.1186/s11671-023-03938-x

2. Mohamed, K. (2019). Nanoimprint Lithography for Nanomanufacturing. Comprehensive Nanoscience and Nanotechnology. doi.org/10.1016/B978-0-12-803581-8.10508-9.

3. Miyauchi, A. (2019). Nanoimprinting and its Applications. [Online] Jenny Stanford Publishing. Available at: https://www.jennystanford.com/9789814800372/nanoimprinting-and-its-applications/

4. Muehlberger, M. (2022). Nanoimprinting of Biomimetic Nanostructures. Nanomanufacturing. doi.org/10.3390/nanomanufacturing2010002

5. Harwell, J., Samuel. (2023). Nanoimprint Lithography as a Route to Nanoscale Back-Contact Perovskite Solar Cells. ACS Applied Nano Materials. doi.org/10.1021/acsanm.3c02493