A NIMS research team has developed a technique that enables the nanoscale observation of heat propagation paths and behavior within material specimens. This was achieved using a scanning transmission electron microscope (STEM) capable of emitting a pulsed electron beam and a nanosized thermocouple—a high-precision temperature measurement device developed by NIMS. The research is published in Science Advances.

Public interest in energy conservation and recycling has grown considerably in recent years. This change has inspired scientists to develop next-generation materials/devices capable of controlling and utilizing heat with a high degree of precision, including thermoelectric devices able to convert waste heat into electricity and heat dissipation composites that can cool electronic components exposed to high temperatures.

It has been difficult to measure nanoscale heat propagation within materials because its characteristics (i.e., the amplitudes, velocities, paths and propagation mechanisms of traveling thermal waves) vary depending on the characteristics of a material (i.e., its composition and size and the types and abundance of defects within it) to which heat is applied. The development of new techniques enabling in-situ observation of how heat flows through the nanostructures of materials had therefore been anticipated.

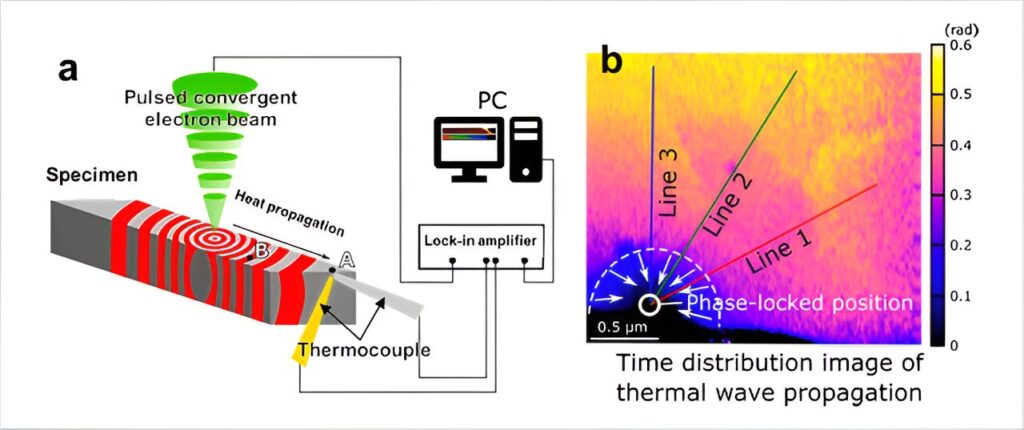

This research team developed a nanoscale heat propagation observation technique using a STEM in which a pulsed nanosized electron beam is applied to a specific site of a material specimen, generating heat which is then measured in the form of changing temperatures using a nanosized thermocouple developed by NIMS.

Irradiating the specimen with a pulsed electron beam enables the periodic measurement of different thermal wave phases and the analysis of thermal wave velocities and amplitudes.

In addition, precise nanoscale repositioning of irradiation sites enables the imaging of temporal changes in thermal wave phases and amplitudes. These images can be used not only to perform nanoscale thermal conductivity measurements but also to create an animated video tracking heat propagation.

The complex relationships between the microstructures of materials and how heat flows through them may be elucidated by observing nanoscale heat propagation using the in-situ technique developed in this project.

The technique may allow the investigation of complex thermal conduction mechanisms within heat dissipation composites, evaluation of interfacial thermal conduction within micro welded joints and in-situ observation of thermal behavior within thermoelectric materials.

This may contribute to the development of high-performance, high-efficiency, next-generation thermal transport materials and thermoelectric materials/devices.