Montana State University researcher James Crawford recently published a collaborative paper with the National Renewable Energy Laboratory that marks a step forward in their quest for what he calls a “holy grail” of chemistry: converting the greenhouse gas carbon dioxide into chemical building blocks that could be used to create myriad other materials.

That paper, “High Selectivity Reactive Carbon Dioxide Capture over Zeolite Dual-Functional Materials,” was published in the journal ACS Catalysis. An atom-scale illustration of the carbon dioxide conversion process is featured on the front cover of the journal.

“We have successfully captured carbon dioxide then converted it into methane and carbon monoxide using functionalized microporous materials,” said Crawford, an assistant professor of chemical and biological engineering in MSU’s Norm Asbjornson College of Engineering. “Methane is a drop-in energy resource compatible with existing natural gas infrastructure. Carbon monoxide has a bad reputation but turns out to be an essential reactant in generating synthetic fuels and chemicals.”

The element carbon is found in all living things. It’s the second-most abundant element in the human body and the fourth-most in the universe. It’s found in biofuels, chemicals, textiles and building materials. It’s also a titular element in carbon dioxide, commonly known as CO2, which makes up less than 1% of Earth’s atmosphere. In addition to being exhaled by humans, the colorless, odorless, heat-trapping gas is one byproduct of burning fossil fuels like oil, natural gas, gasoline and coal.

Existing methods for removing carbon dioxide from the atmosphere mostly result in storing the gas, rather than converting it into new products.

“What we’re trying to do is introduce another way to capture CO2 by locking it up with chemical bonds,” said Crawford, who is also affiliated with MSU’s Energy Research Institute and the Center for Biofilm Engineering. “If you can convert atmospheric gases like carbon dioxide and water into carbon monoxide and hydrogen, you can then combine them to make pretty much any hydrocarbon.”

Hydrocarbons are organic compounds composed entirely of hydrogen and carbon, which makes them useful as the building block for many chemical compounds and materials.

“Biological catalysts, or enzymes, have been upcycling atmospheric gases for billions of years,” he said. “My group is interested in learning about enzymes and copying their function in robust, solid-state catalysts. This would enable their use in harsh industrial processes.”

His team is interested in materials that can selectively wick CO2 from the air and enable the reactions that change the chemical identity of the molecule. “These catalysts must have CO2 attachment sites, as well as reactive structures that permit chemical reconstruction to take place,” Crawford said.

This requires materials with customizable, nano-scale structures, with dimensions measured in billionths of a meter. He is interested in two materials specifically: zeolites, which are ceramic-like materials; and metal-organic frameworks, which have metal nodes connected with organic linkers. Both materials have micropores and chemical “tunability” to create CO2 capture and conversion sites.

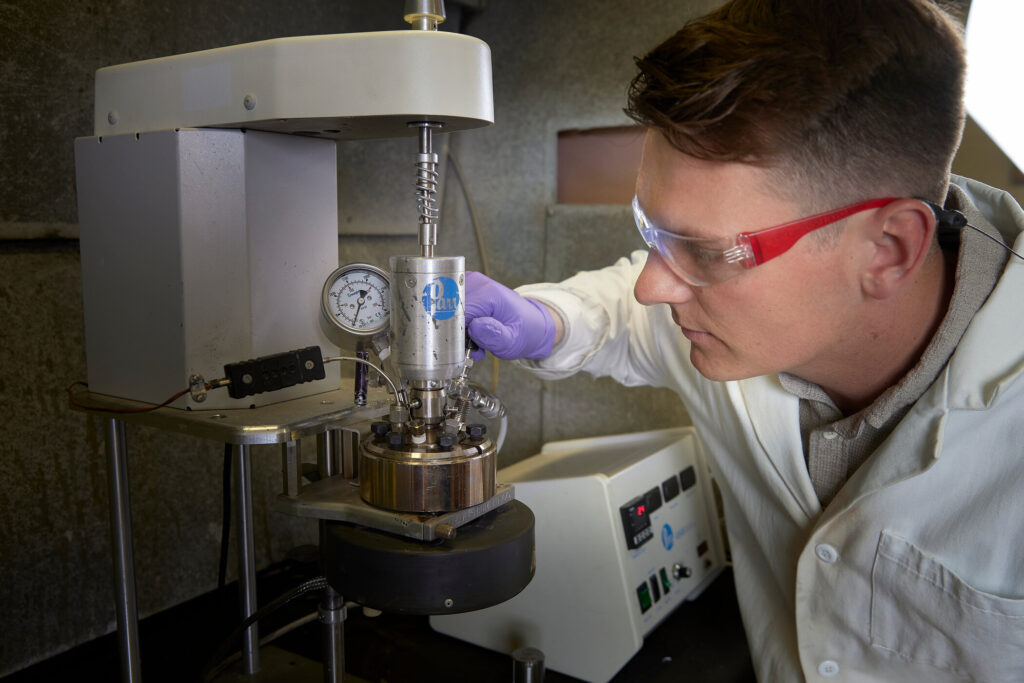

“We generate zeolites and metal-organic frameworks in the lab using a process that combines solvents, heat and pressure to drive the formation of our catalysts,” Crawford said.

Building on these emerging technologies, Crawford, who earned a bachelor’s degree in chemical and biological engineering at MSU before getting his doctorate from the Colorado School of Mines, said he hopes his research will one day lead to designing more efficient nano-catalysts with “biomimetic” properties, meaning they mimic biological processes.

“Biology has figured a lot of this out,” Crawford said. “We are making biomimetic materials that will, one day, be able to steer the CO2 conversion process to generate the chemicals we need the most.”