Accurate 3-axis XY-Theta stages are crucial in various laser precision machining, semiconductor and photonics testing and production, and medical device manufacturing processes. The company offers various solutions for integrated XY-Theta Motion Systems with Industrial Motion Controllers.

Image Credit: PI (Physik Instrumente) LP

These systems can be provided as separate components or complete integrated motion systems with custom interfaces, cable management solutions, vacuum feed-throughs, and application-specific granite and aluminum structures.

XY-Theta Precision Motion and Positioning Assemblies Based on Air Bearing Stages

An ultra-high performance, granite based XY-Theta stage assembly based on an A-322 planar air bearing XY stage with an air bearing rotary table. Image Credit: PI (Physik Instrumente) LP

The engineering teams at PI possess extensive expertise in air-bearing technology and multi-axis motion stage systems.

The exceptional precision of engineered air-bearing positioning systems, coupled with their durable nature, positions them as ideal solutions for semiconductor applications requiring combined linear and rotational motion.

In the image above, a customized, low-profile A-311 Air Bearing Planar XY Motion Table is paired with a high-precision A-621 Series Air Bearing Rotation Stage to create a precise XYT assembly.

XY-Theta Stages, Air Bearing Motion Systems for High Precision Laser Dicing / Processing

XY-Theta air bearing stage based on low profile XY planar stages (model A-311) and direct-drive air bearing Theta-Z stage (model A-623). This compact 3-axis stage is well suited for high performance laser, test & metrology applications. Video Credit: PI (Physik Instrumente) LP

When additional degrees of freedom are needed, XY-stages can be combined with a low-profile Z-Tip-Tilt (ZTT) motion module to form 5-axis systems, like the 5-DOF wafer stage for semiconductor metrology applications seen in the video below. The ZTT module can also be incorporated into XY-Theta stages for 6DOF motion applications.

Improving Wafer Inspection & Metrology w/Air Bearings and Piezo Nanopositioning Stages | PI

5-Axis wafer metrology stage with air bearings. Video Credit: PI (Physik Instrumente) LP

EtherCat®-Based Industrial Motion Controllers

The PI XY-Theta 3-axis stage assemblies utilize ACS Industrial Motion Control components. PI controllers, based on ACS, feature optimized configurations for enhanced application performance.

This includes pre-configured systems with optimized system parameter information for out-of-the-box operation—such as motion-synchronized device triggering through Laser Control Module (LCM) / Laser Control Interface (LCI) hardware, and functional safety features like Safe Torque Off.

The ACS laser control module. Image Credit: PI (Physik Instrumente) LP

XYT Precision Motion and Positioning Assemblies Based on Mechanical Bearing Stages

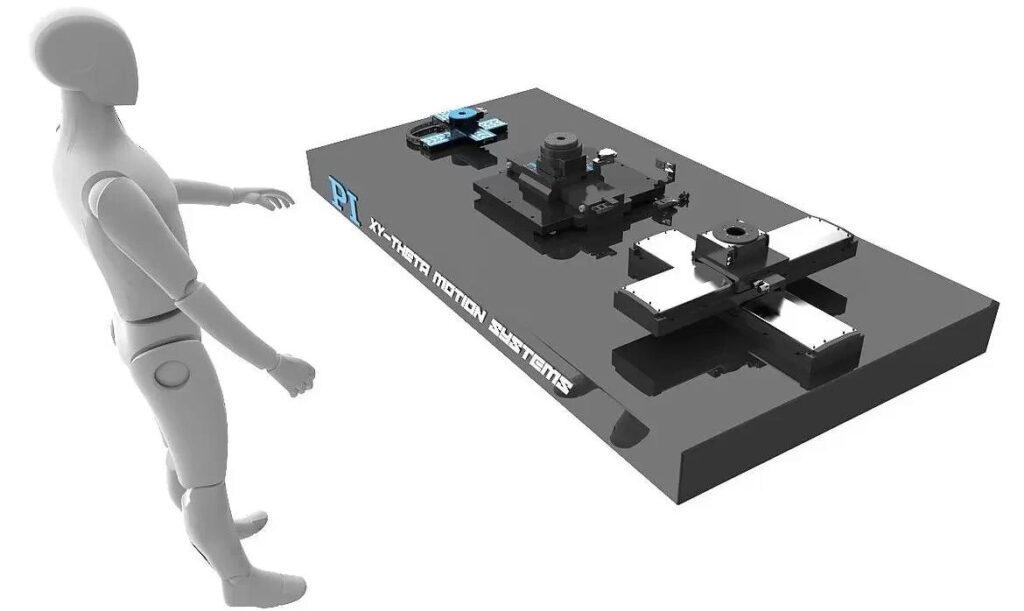

In many applications, compactness plays a crucial role in integrating tools. The V-508 low-profile linear stage and V-610 low-profile rotary stage, part of a direct-drive, multi-axis motion system, exemplify a lightweight, high-performance 3-axis setup.

It is incredibly slim, compact, and technologically adaptable to efficiently handle both rapid step and settle actions, as well as smoothly coordinated scanning tasks within error tolerances spanning from nanometers to microns.

XY-Theta stage assembly with clear aperture for light path, providing 25×80 mm travel. The assembly consists of two V-508 compact linear translation stages and a V-610 direct-drive rotary stage. Image Credit: PI (Physik Instrumente) LP

Precision motion in high-throughput industrial automation often involves repetitive moves with increased loads and accelerations.

The V-817 Series Precision Automation Stage Assembly, featuring a direct-drive rotary table, showcased above, offers high acceleration and duty cycle motion. It utilizes efficient 3-phase linear motors and torque motors, providing substantial continuous and peak force.

The robust stage construction, crafted using aircraft-grade aluminum alloys, ensures the required stiffness to manage high impulses over short durations while maintaining precision.

Employing precision truck and rail bearings further enhances load characteristics and extends operational lifetimes. The integrated high-speed direct-drive rotary stage, with its significant torque output, is pivotal for dynamic step-settle and scanning performance.

PI XY-Theta automation systems are tailored to specific applications, considering travel, performance, load, and space requirements.

The showcased solutions here provide a glimpse of the available options for XYT motion, highlighting the varied assortment of motor, bearing, encoder, and design components that have contributed to PI’s status as a market leader in precision motion.

High-load, high speed direct drive 3-axis XY-Theta automation stage assembly. More information on the V-817 linear translation stage family and its motion controllers. Image Credit: PI (Physik Instrumente) LP

Low profile V-508/V-610 based XYT stage assembly. Image Credit: PI (Physik Instrumente) LP

XYT Stage Assembly Questions – Get Support from an Engineer

The XY-Theta stage solutions featured in this piece represent an array of proprietary technologies developed internally at PI. These encompass motors, encoders, bearings, materials, and design elements. Image Credit: PI (Physik Instrumente) LP

PI stands as a global leader in multi-axis precision motion control, spearheading high-precision linear stages, rotary stages, and multi-axis stages for various high-tech applications.

The continuous enhancements in PI’s high-precision XY-Theta multi-axis motion systems have significantly supported numerous customers in semiconductor manufacturing, laser materials processing, and medical device manufacturing, elevating their throughput and quality levels.

This information has been sourced, reviewed and adapted from materials provided by PI (Physik Instrumente) LP.

For more information on this source, please visit PI (Physik Instrumente) LP.