Graphene field effect transistors offer numerous advantages over traditional CMOS transistors; however, improvements in manufacturing and scalability are necessary before commercialization.

Image Credit: Production Perig/Shutterstock.com

An Introduction to Graphene Field Effect Transistors

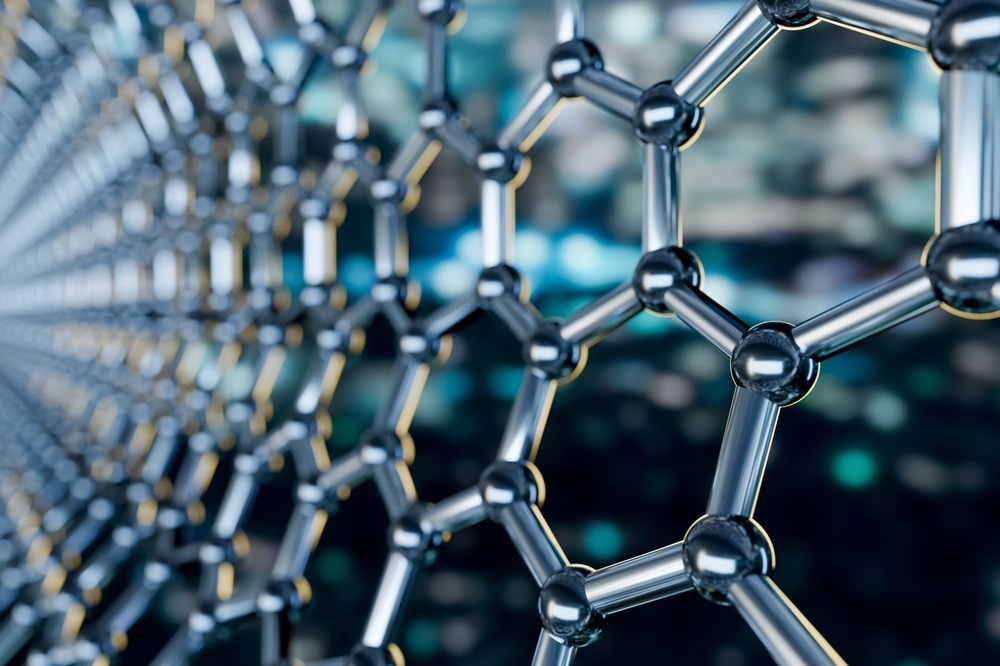

A graphene layer consists of carbon atoms linked by covalent bonds, forming a honeycomb structure. Its excellent electron mobility, chemical and physical stability, electrical and thermal conductivity, and other properties make it promising for various electronic devices.

While silicon is the primary material used in the materials sector, reducing its size to the nanoscale impairs charge transfer efficiency, prompting the search for alternatives.

According to Moore’s law, transistor size should decrease to increase the number of transistors on a chip, resulting in faster processing and increased efficiency.1

Graphene can function as a reliable substitute for silicon in field effect transistors. In graphene field effect transistors (GFETs), graphene replaces silicon as the channel material between the source and drain, leveraging graphene’s exceptional electronic properties for efficient charge transport.1, 2

GFET: Structure, Operation Principles, and Fabrication Techniques

GFETs have a channel made of mono or bilayer graphene, which is extremely thin. The three terminals—source, drain, and gate—regulate charge passage.

The voltage or field applied at the gate terminal regulates the passage of charges between the source and the drain. As monolayer graphene has a high surface-to-volume ratio, surface alterations have a significant impact on the channel, enabling precise control of charge flow.1, 2

The most commonly used method for fabricating GFET channels is mechanical exfoliation. In this process, graphene sheets are separated from one another using adhesive tapes, which are then rubbed against SiO2 to coat them with graphene.

Another technique involves producing graphene epitaxially via a SiC substrate, requiring high temperatures between 1250 and 1450 °C. This method yields a single graphene layer through silicon absorption at elevated temperatures. However, this approach is significantly more expensive than CMOS technology.

Chemical vapor deposition (CVD) utilizes metal substrates such as nickel, ruthenium, and others. The metal is chemically dissolved after deposition, and forced cooling methods cause the graphene sheet to precipitate onto the necessary substrate. Depending on the application, direct deposition can also be performed on flexible substrates like microbial cellulose or rigid substrates like copper or iridium.2,3

Advantages and Applications of GFETs

GFETs offer several advantages over traditional metal oxide semiconductor-based FETs, exhibiting high transconductance gain and electron mobility of 2 x 105 cm2.V-1.s-1.

They also feature a high intrinsic cut-off frequency of 427 GHz and a high carrier density of 1012 cm-2. Graphene’s small band gap of 0.2 eV and high surface-to-volume ratio contribute to the suitability of GFET for various electronic applications.2,3

Due to their extremely thin channels, GFETs are highly sensitive, making surface changes significantly impactful. Surface alterations affect the local electrostatic field, thereby influencing charge flow across the channel.

The graphene channel provides excellent charge mobility through ballistic transport, a defect-free pathway for charges. This improves the response time of GFETs compared to traditional transistors.

GFETs are compatible with high-k dielectric materials, such as SiO2, used in the top and bottom gates. The transistor can be scaled to several nanometers, allowing for more transistors on a chip than standard FETs. Other benefits include optical transparency, high tensile strength, and high thermal conductivity.3

GFETs are used in high-speed analog circuits that can be as small as a few nanometers. They are also utilized in radio frequency equipment, including mixers, frequency multipliers, doublers, and triplers. A primary area of research for GFETs is in biosensing applications. Due to the high surface sensitivity of the graphene channel, GFET-based devices can detect bio-analytes like DNA. Additionally, GFETs are being developed as highly sensitive gas sensors for detecting specific target gases.3,4

Challenges and Limitations

Fabricating defect-free graphene channels is essential for high-charge carrier mobility. Obtaining such graphene sheets for device fabrication is difficult. The scientific community is exploring synthesis methods for producing defect-free graphene.

Integrating manufactured GFET-based devices into existing electronic systems is also problematic. Broad adoption of GFETs depends on developing fabrication technology to produce high-quality GFETs.3,4

The Future of GFETs: Recent Advances and Potential Innovations

GFETs offer an alternative to silicon-based transistors for future electrical applications. They are being investigated for biosensing, conformal sensors, biomedical devices, and flexible electronics.

To design and optimize GFETs, predict device performance, accelerate material discovery, and improve device design, computational techniques, including machine learning AI tools and simulation software, are employed.4

Research is focused on improving scalability, stability, and manufacturability issues to achieve graphene-based integrated circuits. However, efforts are needed to standardize GFET integrated circuits, establish reliability matrices, and commercialize the technology.

Industry-academia collaborations are crucial in translating research discoveries into commercial products, paving the way for scalable production techniques and the widespread adoption of GFET technology.5

More from AZoNano: How Does Atomic Emission Spectroscopy Work?

References and Further Reading

- Schwierz, F. (2010). Graphene transistors. Nature nanotechnology. doi.org/10.1038/nnano.2010.89

- Reddy, D., Register, LF., Carpenter, GD., Banerjee, SK. (2011). Graphene field-effect transistors. Journal of Physics D: Applied Physics. doi.org/10.1088/0022-3727/44/31/313001

- Krsihna, BV., Ravi, S. Prakash, MD. (2021). Recent developments in graphene based field effect transistors. Materials Today: Proceedings. doi.org/10.1016/j.matpr.2020.07.678

- Wang, S., Qi, X., Hao, D., Moro, R., Ma, Y., Ma, L. (2022). Recent advances in graphene-based field-effect-transistor biosensors: A review on biosensor designing strategy. Journal of the Electrochemical Society. doi.org/ 10.1149/1945-7111/ac4f24

- Chandrasekar, L., Pradhan, K.P., 2023. Applications of graphene in electronics: graphene field effect transistors. In Recent Advances in Graphene and Graphene-Based Technologies. doi.org/10.1088/978-0-7503-3999-5ch7