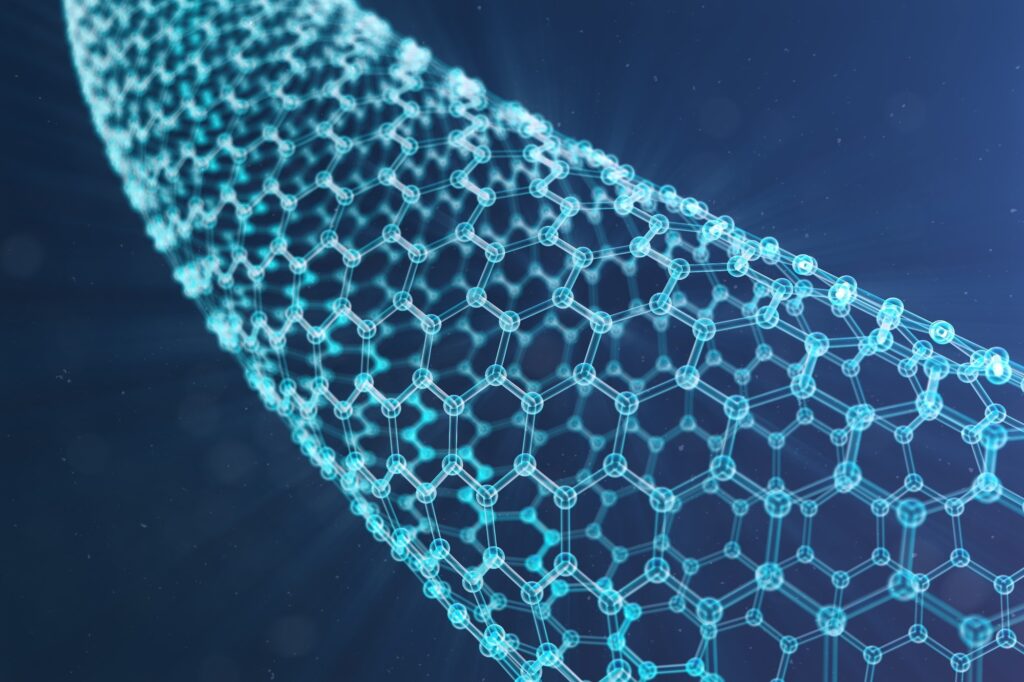

Carbon nanotubes (CNTs) are cylindrical nanostructures made of carbon atoms arranged in a hexagonal lattice. Their remarkable mechanical, electrical, and thermal properties have made them a focal point of research in nanotechnology and materials science.

But what exactly gives carbon nanotubes these extraordinary properties?

Image Credit: Rost9/Shutterstock.com

Structure of Carbon Nanotubes

Carbon nanotubes (CNTs) are cylindrical nanostructures formed by rolling a single layer of graphene into a seamless tube.

The graphene sheet consists of carbon atoms arranged in a hexagonal lattice, with each atom bonded to three others. This structure can be visualized as a sheet of chicken wire rolled into a cylinder.

The atomic structure of a CNT is defined by its chiral indices (n,m), which specify the perimeter vector (chiral vector) and determine the tube’s diameter and helicity. The chiral vector connects two carbon atoms on the graphene plane, and the nanotube is formed by rolling the sheet to connect these atoms.

How are Carbon Nanotubes Made from Graphene?

There are two primary types of carbon nanotubes:

1. Single-walled carbon nanotubes (SWCNTs):

SWCNTs consist of a single layer of graphene rolled into a cylindrical structure. Their diameter typically ranges from 0.4 to 2 nanometers, while their length can extend to several micrometers.

The properties of SWCNTs are highly dependent on their chirality and diameter. They can be metallic or semiconducting based on how the graphene sheet is rolled (characterized by the chiral vector).

SWCNTs can be open-ended or capped with fullerene-like structures at one or both ends.

2. Multi-walled carbon nanotubes (MWCNTs):

MWCNTs comprise multiple layers of graphene cylinders nested within one another. There are two structural models for MWCNTs:

- Russian Doll model: This consists of concentric SWCNTs with increasing diameters. The interlayer distance in these structures is close to the interlayer spacing in graphite (approximately 0.34 nm).

- Parchment model: This is formed by a single sheet of graphene rolled around itself, resembling a scroll of parchment or a rolled newspaper. The interlayer distance in this model can vary.

MWCNTs typically have diameters ranging from 2 to 100 nanometers, depending on the number of layers.

They generally exhibit metallic electrical behavior due to the statistical probability that at least one of the layers will be metallic.

Carbon Nanotube Properties

Strength

CNTs are among the strongest materials ever discovered. They are about 100 times stronger than high steel, with tensile strengths reaching up to 63 GPa for MWCNTs and approximately 100 GPa for individual CNT shells. This strength is attributed to the covalent sp² bonds between carbon atoms, which form a highly stable hexagonal lattice.

Additionally, CNTs are molecularly perfect, meaning they lack grain boundaries or defects that typically weaken other materials like steel. Their specific strength is unmatched, with values up to 48,000 kN·m/kg compared to high-carbon steel’s 154 kN·m/kg.

Despite their exceptional tensile strength, CNTs are less resistant to compressive forces due to buckling under pressure.

Thermal Conductivity

CNTs exhibit extraordinary thermal conductivity, with values reaching up to 4000 W/m·K, far exceeding diamond’s maximum of approximately 1200 W/m·K.

This property arises from the efficient transmission of phonons (quantized lattice vibrations) along the nanotube’s axis. The anisotropic nature of CNTs means thermal conductivity is significantly higher parallel to the tube axis than perpendicular to it.

The clean and defect-free structure of SWCNTs further enhances phonon transmission.

Electrical Conductivity

CNTs behave as one-dimensional conductors due to their nanoscale cross-section, allowing electrons to propagate primarily along the tube’s axis.

Their electrical properties depend on chirality: armchair CNTs are metallic, while zigzag and chiral CNTs can be semiconducting or metallic.

Doping techniques can further modify their conductivity by introducing p-type or n-type behavior through substitutional or adsorbed dopants.

Flexibility and Toughness

CNTs combine high strength with remarkable flexibility, allowing them to bend without breaking. Their Young’s modulus is approximately 1 TPa, making them five times stiffer than steel.

Lightweight

CNTs have a density of about 1.3–1.4 g/cm³, which is significantly lower than steel (approximately one-quarter). This low density contributes to their high specific strength and makes them suitable for aerospace and structural applications.

NASA’s Conductive Polymer/Carbon Nanotube Structural Materials and Methods