Semiconducting polymer nanomaterials are advanced π-conjugated polymers with alternating double and single bonds, which allow for π-electron delocalization and intermolecular π−π interactions. Unlike the ordered lattice structures of inorganic semiconductors, these polymers exhibit structural and energetic disorder, which affects their electronic transport and optoelectronic properties.1

Image Credit: KRAUCHANKA HENADZ/Shutterstock.com

These materials work through frontier molecular orbitals—the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO)—to describe their energy levels and charge transport mechanisms. This is comparable to the valence and conduction bands in inorganic semiconductors.

Properties of Semiconducting Polymer Nanomaterials

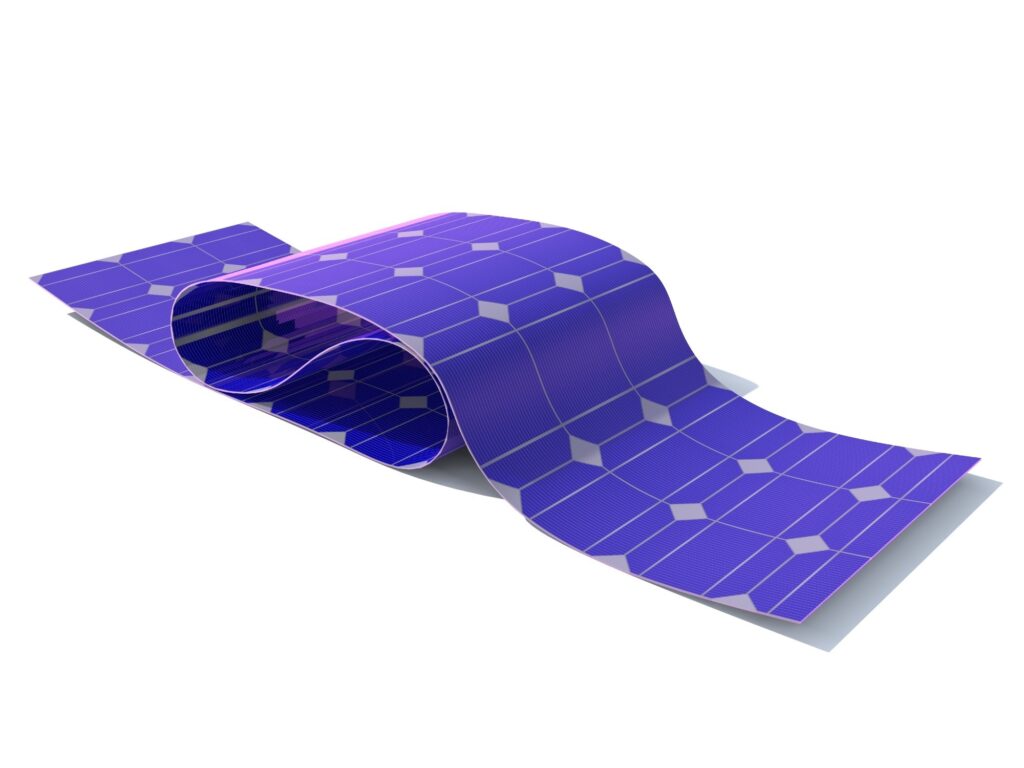

Semiconducting polymer nanomaterials combine flexibility with distinct electronic properties, making them suitable for a range of technological applications. These materials are inherently conductive and highly flexible, allowing integration into lightweight, stretchable devices.1,2

Their flexibility comes from their polymeric backbone, which can be tuned to balance mechanical adaptability with electrical performance. This makes them well-suited for wearable electronics and foldable devices, where rigid materials are less practical.2,3

Charge transport in these materials is influenced by molecular packing and chain alignment, with π−π stacking interactions playing a crucial role. While their intrinsic disorder limits charge mobility compared to inorganic semiconductors (such as silicon, with >100 cm2/V·s mobility), semiconducting polymers typically achieve mobilities in the range of approximately 0.1–10 cm2/V·s. Advances in molecular design and processing techniques, such as solvent annealing or thermal treatments, improve crystallinity and charge carrier pathways, enhancing overall performance.

Nanostructuring these materials enhances their functionality. Adjusting their structure at the nanoscale improves charge transport and maximizes surface area, which strengthens interactions with light or other environmental inputs.

For instance, phase separation or templating techniques can improve molecular ordering and interfacial energy level alignment, optimizing charge injection and extraction. This is essential for applications like energy harvesting and sensing. Nanostructuring also provides greater control over electron-hole recombination dynamics, improving the efficiency of optoelectronic devices.2,3

These materials exhibit tunable optoelectronic properties, with bandgaps typically ranging between approximately 1.5–3.0 eV, making them versatile for applications requiring specific absorption or emission characteristics. This customizability broadens their applications, from energy storage systems to environmental and biological sensors.4

Semi Conducting Polymers The New Horizons and Unmet Future Challenges Webinar

Applications of Semiconducting Polymer Nanomaterials

Organic Electronics

Semiconducting polymer nanomaterials are widely used in organic electronics due to their flexibility, cost-efficient processing, and compatibility with scalable manufacturing methods such as roll-to-roll production. They play a key role in devices like organic light-emitting diodes (OLEDs) for light emission, flexible displays, and organic solar cells for energy conversion.2

Advanced polymers such as PEDOT:PSS, known for their high conductivity and solution processability, improve the performance and commercial viability of these devices. For instance, Song et al. developed a method using PEDOT:PSS as an electrode to fabricate flexible organic solar cells (OSCs), achieving a power conversion efficiency of 10.12 %, which is a significant step toward commercializing flexible OSCs.5

Energy Storage

In energy storage, semiconducting polymer nanomaterials demonstrate high charge storage capacity and mechanical adaptability, making them suitable for lightweight, flexible supercapacitors and batteries.

For example, polymer-based supercapacitors use pseudocapacitance mechanisms, providing enhanced specific capacitance, high conductivity, and fast charge-discharge cycles. Conducting polymers like polyaniline (PANI) and PEDOT:PSS, when combined with carbon materials, deliver excellent performance and cycling stability, enabling their use in wearable and portable energy storage systems.1, 6

A recent study by Teng et al. developed flexible supercapacitors using acid-treated PEDOT:PSS/PPy hybrid fibers created through in situ pyrrole polymerization on a PEDOT:PSS hydrogel scaffold. The resulting porous, conductive electrode required no additional current collector and showed strong performance due to enhanced ionic conductivity and π−π interactions. The device retained 56.7 % capacitance after 10,000 cycles and achieved a 71.4 % increase at 5.0 A cm-3.6 These developments are particularly useful for emerging applications like fiber-shaped energy storage devices.

Sensors

Semiconducting polymer nanomaterials are also used in sensor technologies. They offer high sensitivity and adaptability to chemical or biological changes. Flexible sensors based on these materials are lightweight and cost-effective, making them ideal for environmental monitoring and healthcare diagnostics.1,2

For instance, resistive and piezoelectric sensors built on polymer substrates can accurately detect minute deformations, chemical changes, or biological signals. The ability to engineer these polymers for specific sensitivities has enabled the development of innovative sensor systems that are durable, portable, and compatible with wearable technologies.7

In one study, Dong et al. used ZnO nanowires (NWs) as the optical sensing layer in a p-n junction-based self-powered UV photodetector. The self-powered functionality was achieved by the junction formed between ZnO NWs and poly(N-vinyl carbazole) (PVK).8

Addressing the Challenges of Semiconducting Polymer Nanomaterials

One of the primary challenges semiconducting polymer nanomaterials face is their limited durability and environmental stability. These materials are highly susceptible to degradation when exposed to external factors such as oxygen, moisture, light, and temperature fluctuations.2

For example, prolonged exposure to light causes photooxidation and cross-linking, reducing electrical performance. Similarly, oxidants and water vapor accelerate chemical degradation, further shortening the operational life of these materials.1,2

Another issue is the mechanical and chemical mismatch between layered structures in devices. Interfaces in semiconducting polymer systems are prone to separation and peeling under repeated bending or stretching, which is common in flexible applications. These instabilities lower device performance and durability, creating barriers to commercialization.1,2

Manufacturing these materials at an industrial scale also remains complex. Their unique properties, such as molecular structure and spinnability, often conflict with conventional large-scale production methods.2

Addressing these issues requires advancements in material design. Improving the molecular weight and backbone rigidity of polymers can enhance their resistance to environmental degradation. Integrating innovative processing techniques, such as thermal drawing or 3D printing, with traditional spinning methods could help scale up production while maintaining performance.1

For further reading on related topics, check out the following articles:

References and Further Reading

1. Sun, F.; Jiang, H.; Wang, H.; Zhong, Y.; Xu, Y.; Xing, Y.; Yu, M.; Feng, L.-W.; Tang, Z.; Liu, J. (2023) Soft Fiber Electronics Based on Semiconducting Polymer. Chemical Reviews. https://pubs.acs.org/doi/10.1021/acs.chemrev.2c00720

2. Li, L.; Han, L.; Hu, H.; Zhang, R. (2023). A Review on Polymers and Their Composites for Flexible Electronics. Materials Advances. https://pubs.rsc.org/en/content/articlelanding/2023/ma/d2ma00940d

3. Ávila-Niño, J. A.; Herrera-Celis, J. (2024). Semiconducting Polymers for a New Generation of Electrochemical Sensors. Semiconducting Polymer Materials for Biosensing Applications. https://www.sciencedirect.com/science/article/abs/pii/B9780323951050000139?via%3Dihub

4. Del Valle, M.; Gacitúa, M.; Hernández, F.; Luengo, M.; Hernández, L. (2023). Nanostructured Conducting Polymers and Their Applications in Energy Storage Devices. Polymers. https://www.mdpi.com/2073-4360/15/6/1450

5. Song, W.; Fan, X.; Xu, B.; Yan, F.; Cui, H.; Wei, Q.; Peng, R.; Hong, L.; Huang, J.; Ge, Z. (2018). All‐Solution‐Processed Metal‐Oxide‐Free Flexible Organic Solar Cells with over 10% Efficiency. Advanced Materials. https://advanced.onlinelibrary.wiley.com/doi/abs/10.1002/adma.201800075

6. Teng, W.; Zhou, Q.; Wang, X.; Che, H.; Hu, P.; Li, H.; Wang, J. (2020). Hierarchically Interconnected Conducting Polymer Hybrid Fiber with High Specific Capacitance for Flexible Fiber-Shaped Supercapacitor. Chemical Engineering Journal. https://www.sciencedirect.com/science/article/abs/pii/S138589472030560X?via%3Dihub

7. Deng, S.; Li, L.; Zhang, J.; Wang, Y.; Huang, Z.; Chen, H. (2023). Semiconducting Polymer Dots for Point-of-Care Biosensing and in Vivo Bioimaging: A Concise Review. Biosensors. https://pmc.ncbi.nlm.nih.gov/articles/PMC9855952/

8. Dong, Y.; Zou, Y.; Song, J.; Zhu, Z.; Li, J.; Zeng, H. (2016). Self-Powered Fiber-Shaped Wearable Omnidirectional Photodetectors. Nano Energy. https://www.sciencedirect.com/science/article/abs/pii/S2211285516304281