X-ray diffraction (XRD) is a non-destructive analytical technique used to determine the atomic and molecular structure of materials by measuring how X-rays scatter. It provides key information about a material’s phases, crystalline structure, average crystallite size, strain, orientation, texture, and defects.1 XRD is widely applied in nanomaterial science for structural characterization.

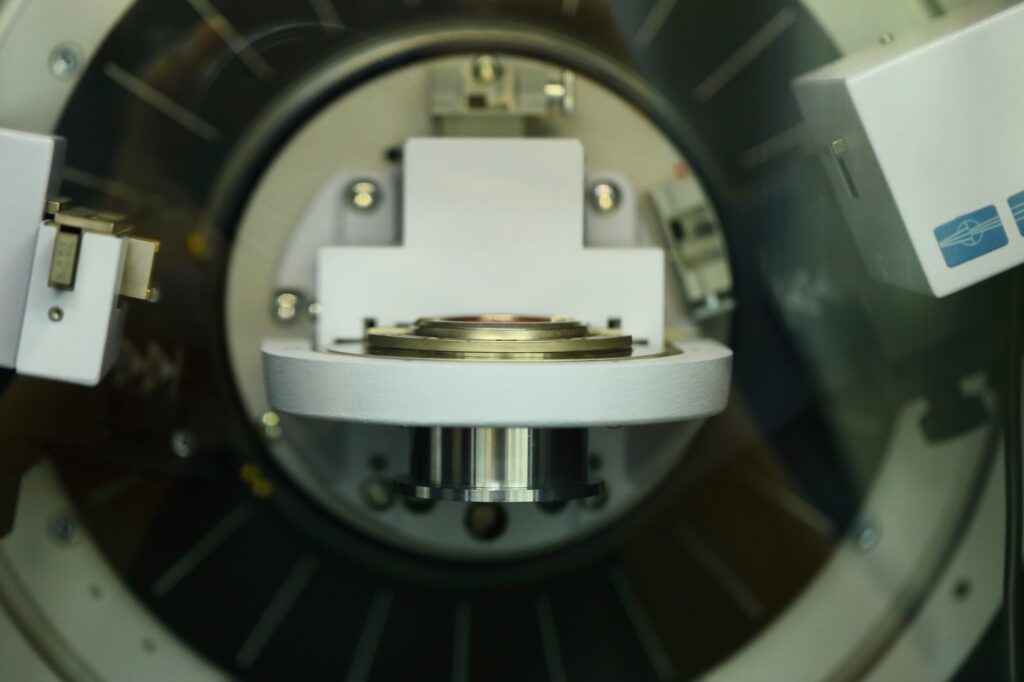

Image Credit: AgriTech/Shuttertsock.com

Principle of XRD

XRD works by directing X-rays onto a crystalline material and analyzing the angles and intensities of the diffracted beams. The atomic planes within the crystal act as a three-dimensional grating, scattering the X-rays in specific directions. This scattering produces a unique diffraction pattern consisting of intense spots known as Von Laue or Bragg diffraction spots.1-2

The diffraction pattern provides crucial structural information, including the material’s symmetry, orientation, and phase. The relationship between the incident X-rays and the atomic planes is governed by Bragg’s Law, expressed as:

2d sinθ = nλ

Where:

- n is an integer representing the diffraction order.

- λ is the wavelength of the incident X-rays.

- d is the interplanar spacing in the crystal.

- θ is the angle of incidence of the X-rays.

When the conditions of Bragg’s Law are satisfied, constructive interference occurs, producing the diffraction peaks observed in the XRD pattern. By analyzing these peaks, the interplanar spacing d can be calculated, providing insight into the crystal structure.1-2

An XRD diffractogram represents the intensity of diffracted X-rays as a function of the diffraction angle 2θ. Each peak corresponds to a specific set of crystallographic planes, allowing researchers to identify the crystal structure and phase composition by comparing the pattern to reference databases such as the International Crystallographic Diffraction Data (ICDD).2

In addition to phase identification, XRD can measure lattice parameters and detect crystal imperfections, including strain, dislocations, and stacking faults.2 These insights are important for analyzing the structural properties of crystalline materials, establishing XRD as a widely used tool in nanomaterial science.

What is X-ray Diffraction?

Applications in Nanomaterials

XRD is highly versatile and used to study bulk materials, polycrystalline thin films, multilayer structures, and various nanostructures, such as quantum wells, quantum dots, and nanorods. It is also effective for analyzing amorphous materials by examining diffuse scattering patterns with methods like the atomic pair distribution function (PDF).1 Key applications include:

- Nanoparticle Characterization: XRD determines crystallite size, phase composition, and crystalline structure in nanoparticles. By analyzing diffraction patterns and applying the Scherrer equation, researchers estimate particle size and assess crystallinity. XRD also identifies phases by comparing diffraction peaks to reference data, ensuring phase purity and structural consistency. This is particularly critical in applications such as catalysis, drug delivery, and sensors.3

- Thin Films: For nanostructured thin films, XRD characterizes layer thickness, orientation, and uniformity. Grazing Incidence X-ray Diffraction (GIXRD) enables precise surface and near-surface analysis without deep X-ray penetration. XRD also evaluates preferred crystallographic orientation (texture), lattice strain, and residual stress, which are crucial for optimizing thin films used in electronics, optics, and coatings.1,3

- Nanostructured Powders: In nanostructured powders, XRD provides insights into phase purity, crystallinity, and phase transitions. It detects impurities and quantifies crystallinity by analyzing the sharpness and intensity of diffraction peaks. XRD also monitors structural changes during heat treatments or chemical modifications, ensuring stability and purity in ceramics, pharmaceuticals, and advanced composites.1, 4

Advantages and Challenges of XRD in Nanomaterial Analysis

One major advantage of XRD is its non-destructive nature, which allows researchers to gather detailed structural information without altering or damaging samples. This feature is especially important for analyzing delicate nanomaterials. XRD also enables repeated analysis of the same sample under different conditions and can be combined with other techniques for more comprehensive characterization.

XRD provides high accuracy and resolution, detecting subtle changes in lattice parameters, phase composition, and crystalline quality. For nanoparticles smaller than 100 nm, XRD reveals broadening of Bragg peaks, enabling precise estimation of particle size, crystallinity, and strain.5-6 Its versatility across different material types—including metals, ceramics, polymers, and composites—makes XRD an essential tool for developing nanomaterials with tailored properties.

Despite its strengths, XRD has limitations, particularly when analyzing amorphous nanomaterials or complex multi-phase systems. Since XRD detects long-range atomic order, it struggles with amorphous materials, which lack regular atomic patterns. In such cases, the diffraction signals appear as broad, diffuse patterns rather than distinct Bragg peaks.7

For complex multi-phase systems, overlapping diffraction peaks can complicate phase identification and quantification. In such cases, diffraction patterns may become too convoluted to distinguish individual phases accurately, requiring supplementary techniques for a complete analysis.7

Precise and reliable XRD data require strict control of experimental conditions. Factors such as sample preparation, temperature, and instrument calibration must be carefully managed. Nanomaterials, often smaller than 100 nm, produce broad diffraction peaks that can result in intensity loss, making the peaks harder to detect and analyze.4, 7

Accurate measurements in XRD require precise alignment of the X-ray source, sample, and detector, as well as stable environmental conditions to minimize errors caused by vibrations or temperature fluctuations. Variations in these parameters can result in inaccuracies when determining crystallite size, lattice strain, and phase composition.8

Despite these challenges, XRD remains an essential starting point for characterizing nanomaterials. For a more comprehensive analysis, it is often combined with complementary techniques such as Electron Microscopy (TEM/SEM), Raman Spectroscopy, or Pair Distribution Function (PDF) Analysis.7-8

References and Further Readings

1. Pandey, A.; Dalal, S.; Dutta, S.; Dixit, A. (2021). Structural Characterization of Polycrystalline Thin Films by X-Ray Diffraction Techniques. Journal of Materials Science: Materials in Electronics. https://link.springer.com/article/10.1007/s10854-020-04998-w

2. Ali, A.; Chiang, Y. W.; Santos, RM. (2022). X-Ray Diffraction Techniques for Mineral Characterization: A Review for Engineers of the Fundamentals, Applications, and Research Directions. Minerals. https://www.mdpi.com/2075-163X/12/2/205

3. Kaliva, M.; Vamvakaki, M. (2020). Nanomaterials Characterization. Polymer Science and Nanotechnology.

4. Kumar, PS.; Pavithra, KG.; Naushad, M. (2019). Characterization Techniques for Nanomaterials. Nanomaterials for Solar Cell Applications. https://www.sciencedirect.com/science/article/abs/pii/B9780128133378000047?via%3Dihub

5. Linkov, P.; Artemyev, M.; Efimov, AE.; Nabiev, I. (2013). Comparative Advantages and Limitations of the Basic Metrology Methods Applied to the Characterization of Nanomaterials. Nanoscale. https://pubs.rsc.org/en/content/articlelanding/2013/nr/c3nr02372a

6. Salame, PH.; Pawade, VB.; Bhanvase, BA., Characterization Tools and Techniques for Nanomaterials. Nanomaterials for Green Energy. https://www.sciencedirect.com/science/article/abs/pii/B9780128137314000035?via%3Dihub

7. Mudalige, T.; Qu, H.; Van Haute, D.; Ansar, SM.; Paredes, A.; Ingle, T., Characterization of Nanomaterials: Tools and Challenges. (2019). Nanomaterials for food applications. https://www.sciencedirect.com/science/article/abs/pii/B9780128141304000117?via%3Dihub

8. Kadam, YK.; Solanki, KD.; Shaikh, MS.; Savle, AM.; Malek, NI.; Mishra, N., Characterization Methods for Nanomaterials. Exploring Nanomaterial Synthesis, Characterization, and Applications. https://www.irma-international.org/viewtitle/360089/?isxn=9798369363263