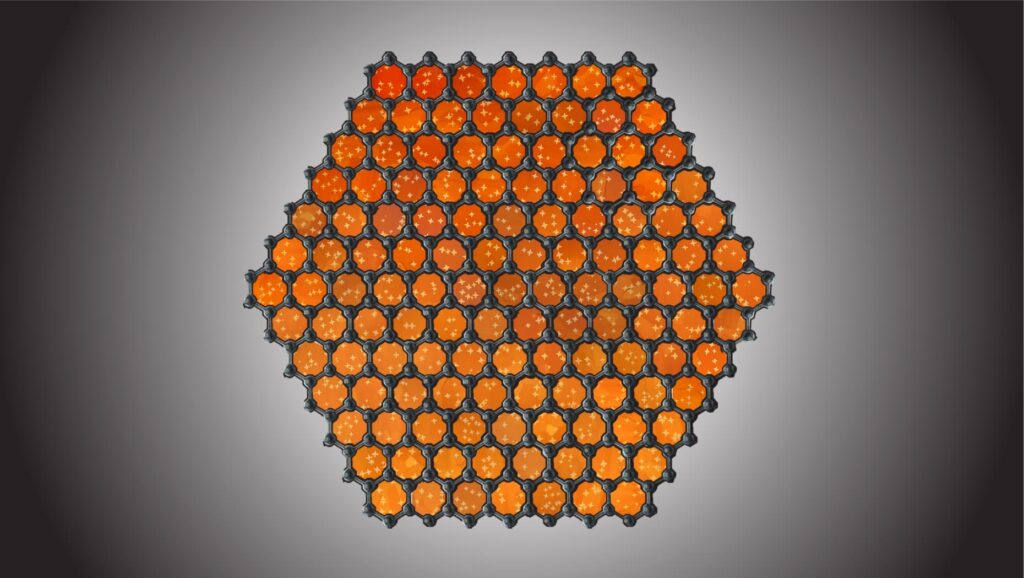

The Hone lab at Columbia Engineering created over 100 identical graphene samples with their oxygen-free chemical vapor deposition method. Credit: Jacob Amontree & Christian Cupo, Columbia University

Columbia Engineers link oxygen to graphene quality and develop new techniques to reproducibly manufacture the wonder material at scale.

Graphene has been called “the wonder material of the 21st century.” Since its discovery in 2004, the material—a single layer of carbon atoms—has been touted for its host of unique properties, which include ultra-high electrical conductivity and remarkable tensile strength. It has the potential to transform electronics, energy storage, sensors, biomedical devices, and more. But graphene has had a dirty little secret: it’s dirty.

Breakthrough in Graphene Synthesis

Now, engineers at Columbia University and colleagues at the University of Montreal and the National Institute of Standards and Technology (NIST) are poised to clean things up with an oxygen-free chemical vapor deposition (OF-CVD) method that can create high-quality graphene samples at scale. Their work, published on May 29 in Nature, directly demonstrates how trace oxygen affects the growth rate of graphene and identifies the link between oxygen and graphene quality for the first time.

“We show that eliminating virtually all oxygen from the growth process is the key to achieving reproducible, high-quality CVD graphene synthesis,” said senior author James Hone, Wang Fong-Jen Professor of Mechanical Engineering at Columbia Engineering. “This is a milestone towards large-scale production of graphene.”

Historical Methods of Graphene Production

Graphene has historically been synthesized in one of two ways. There’s the “scotch-tape” method, in which individual layers are peeled from a bulk sample of graphite (the same material you’ll find in pencil lead) using household tape. (See video below.) Such exfoliated samples can be quite clean and free from impurities that would otherwise interfere with graphene’s desirable properties. However, they tend to be too small—just a few tens of micrometers across–for industrial-scale applications and, thus, better suited for lab research.

To move from lab explorations to real-world applications, researchers developed a method to synthesize large-area graphene about 15 years ago. This process, known as CVD growth, passes a carbon-containing gas, such as methane, over a copper surface at a temperature high enough (about 1000 °C) that the methane breaks apart and the carbon atoms rearrange to form a single honeycomb-shaped layer of graphene.

Challenges With Traditional CVD Growth

CVD growth can be scaled up to create graphene samples that are centimeters or even meters in size. However, despite years of effort from research groups around the world, CVD-synthesized samples have suffered from problems with reproducibility and variable quality.

The issue was oxygen. In prior publications, co-authors Richard Martel and Pierre Levesque from Montreal had shown that trace amounts of oxygen can slow the growth process and even etch the graphene away. So, about six years ago, Christopher DiMarco, GSAS’19, designed and built a CVD growth system in which the amount of oxygen introduced during the deposition process could be carefully controlled.

Advances in Oxygen-Free CVD Growth

Current PhD students Xingzhou Yan and Jacob Amontree continued DiMarco’s work and further improved the growth system. They found that when trace oxygen was eliminated, CVD growth was much faster—and gave the same results every time. They also studied the kinetics of oxygen-free CVD graphene growth and found that a simple model could predict growth rate over a range of different parameters, including gas pressure and temperature.

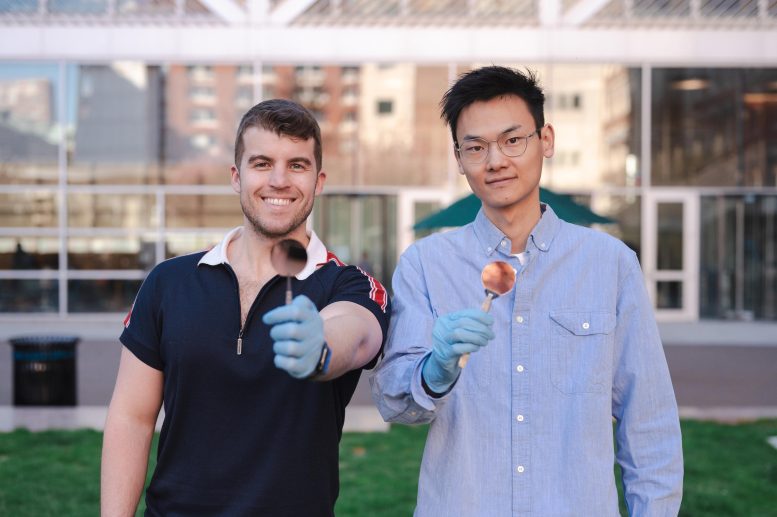

Jacob Amontree (left) and Xingzhou Yan (right) displaying their pristine CVD graphene synthesized on ultra-flat copper/sapphire wafers. Credit: Zhiying Wang, Columbia University

Future Prospects and Applications

The quality of the OF-CVD-grown samples proved virtually identical to that of exfoliated graphene. In collaboration with colleagues in Columbia’s physics department, their graphene displayed striking evidence for the fractional quantum Hall effect under magnetic fields, a quantum phenomenon that had previously only been observed in ultrahigh-quality, two-dimensional electrical systems.

From here, the team plans to develop a method to cleanly transfer their high-quality graphene from the metal growth catalyst to other functional substrates such as silicon — the final piece of the puzzle to take full advantage of this wonder material.

“We both became fascinated by graphene and its potential as undergraduates,” Amontree and Yan said. “We conducted countless experiments and synthesized thousands of samples over the past four years of our PhDs. Seeing this study finally come to fruition is a dream come true.”

Reference: “Reproducible graphene synthesis by oxygen-free chemical vapour deposition” by Jacob Amontree, Xingzhou Yan, Christopher S. DiMarco, Pierre L. Levesque, Tehseen Adel, Jordan Pack, Madisen Holbrook, Christian Cupo, Zhiying Wang, Dihao Sun, Adam J. Biacchi, Charlezetta E. Wilson-Stokes, Kenji Watanabe, Takashi Taniguchi, Cory R. Dean, Angela R. Hight Walker, Katayun Barmak, Richard Martel and James Hone, 29 May 2024, Nature.

DOI: 10.1038/s41586-024-07454-5

The work was initiated by Mechanical Engineering PhD student Christopher DiMarco and continued by current PhD students Xingzhou Yan and Jacob Amontree, who have spent the past four years modifying the system and conducting the experiments that are shown in the paper. The work was supervised by Prof. James Hone (Mechanical Engineering) and co-led by Prof. Katayun Barmak (APAM), with Prof. Abhay Pasupathy and Prof. Cory Dean (Physics) providing key contributions. Postdoc Madisen Holbrook (Physics) imaged the graphene atomic lattice, and PhD students Christian Cupo and Zhiying Wang (MECE) helped with data analysis and measurements. Physics PhD students Jordan Pack, Dihao Sun, and Adam Biachhi performed key electrical measurements.

Richard Martel and Pierre Levesque at the University of Montreal helped guide the research and test the reproducibility of the results. Dr. Angela Hight-Walker’s team at the National Institute for Standards and Technology, in particular Dr. Tehseen Adel and Dr. Charlezetta Wilson-Stokes, characterized the graphene.