A recent study published in Nature Electronics discusses stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics.

Stretchable and conductive nanocomposites with mechanically soft, thin and biocompatible features play vital roles in developing wearable skin-like devices, smart soft robots and implantable bioelectronics.

Although several design strategies involving surface engineering have been reported to overcome the mechanical mismatch between the brittle electrodes and stretchable polymers, it is still challenging to realize monolithic integration of various components with diverse functionalities using the current ultrathin stretchable conductive nanocomposites. This is attributed to the lack of suitable conductive nanomaterial systems compatible with facile patterning strategies.

Laser-induced graphene (LIG), typically derived from laser irradiation of polyimide (PI), has various distinct merits, such as facile digital patterning processes, compatibility with pattern transfer approaches, as well as tunable physical and chemical features to produce diverse wearable sensors.

However, these multifunctional devices are constructed on flexible PI substrates or relatively thick elastic films owing to the mechanical limitations in transferring LIG to soft elastomers. In addition, the mechanical mismatch between the brittle LIG and elastic polymer hinders the stretchability of conductive nanocomposites.

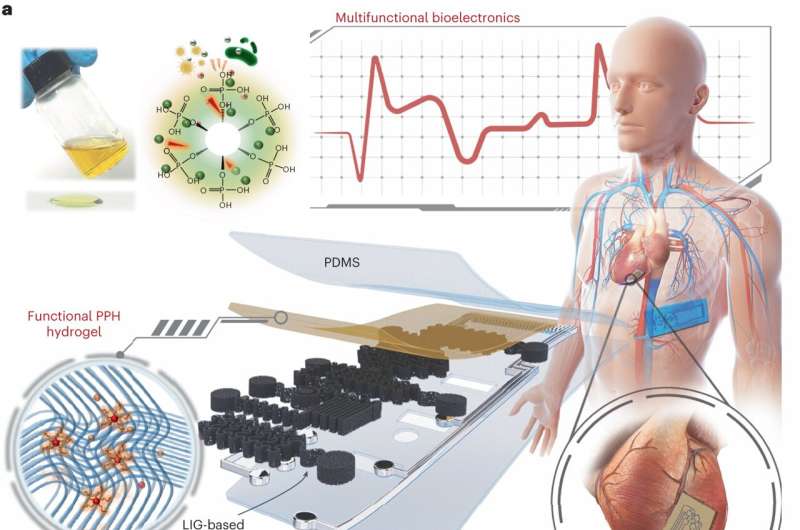

The authors of the article describe an ultrathin elastic LIG-hydrogel-based nanocomposite for multifunctional on-skin and implantable bioelectronics. A new strategy is proposed to create ultrathin patterned LIG-based nanocomposite, which is formed by cryogenically (77 K) transferring LIG to a hydrogel film (minimum thickness of 1.0 μm). Then the mechanical mismatch between the brittle LIG and elastic polymer, which employs the hydrogel as an energy dissipation interface and out-of-plane electrical path is addressed.

Continuously deflected cracks can be induced in the LIG leading to an over five-fold enhancement in intrinsic stretchability. Overall, this research provides a viable strategy to construct ultrathin carbon-hydrogel-based stretchable nanocomposites for integrated sensor systems, enabling diverse applications in wearable/implantable bioelectronics and human-machine interactions.

Kaichen Xu, corresponding author, noted, “Conventional LIG transfer method requires the much larger thickness (>45 μm) of elastomers or adhesive tapes to provide a strong interfacial force during the peeling-off process, hindering the conformal bioelectronics applications. The mechanical restrictions in transferring LIG to elastomers are overcome by a cryogenic transfer approach at –196℃ using an ultrathin and adhesive polyvinyl alcohol/phytic acid/honey (PPH) hydrogel.”

During the fast cooling process, the interfacial binding energy between defective porous graphene and the crystallized water within hydrogel is enhanced, as illustrated by molecular dynamics (MD) calculations. Such a dramatic increase in superficial binding force at 77 K was also captured in the 180° peeling test. The maximum transient peeling force of 160 N m-1 at 77 K was observed, which was much higher than that (<10 N m-1) originating from the autologous adhesion of PPH at the ambient temperature.

Furthermore, the proposed cryogenic transfer strategy allowed the transfer of LIG onto other types of adhesive or non-adhesive hydrogels, indicating the universality of this transfer technology. Nevertheless, only the adhesive hydrogel formed a mechanically stable binding interface, especially under the tensile strain.

Through the facile laser direct writing and cryogenic transfer technique, multimodal sensor components are integrated as a multifunctional wearable sensor sheet for on-skin in vitro monitoring. Furthermore, the ultrathin and biocompatible characteristics of the micropatterned LIG-based nanocomposites allow seamless contact with the heart of Sprague Dawley (SD) rats to in situ track cardiac signals.

Provided by

Compuscript Ltd