Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice.

Image Credit: G. Soler Tomasella/Shutterstock.com

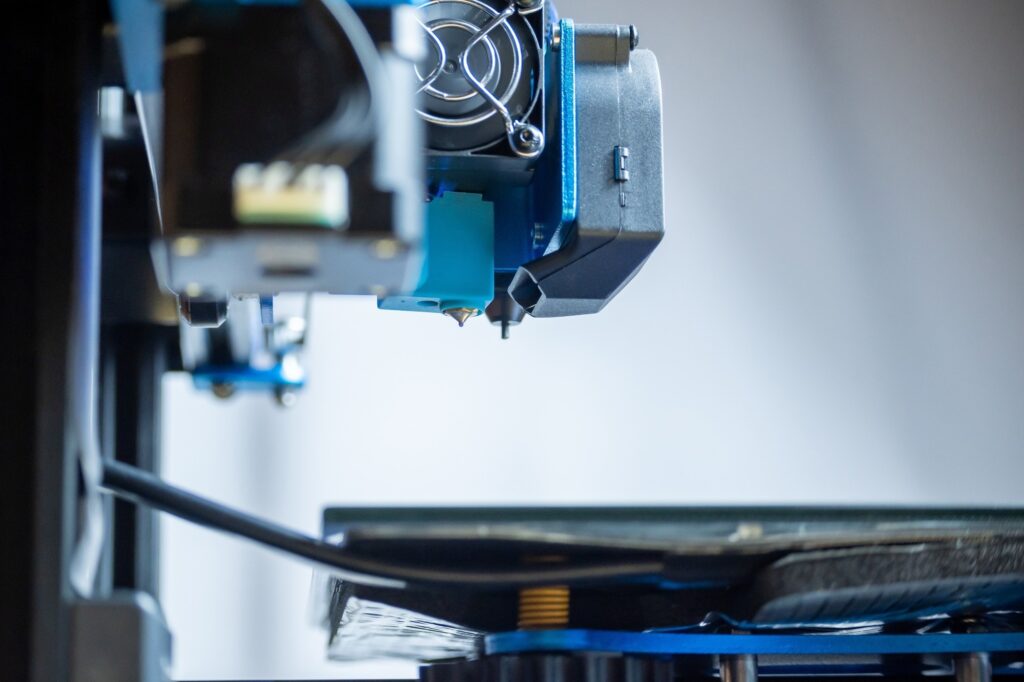

Graphene is known for its excellent electrical conductivity, mechanical strength, and thermal stability. Recent advancements have enabled the integration of graphene into 3D printing, allowing the creation of custom structures that combine graphene’s unique properties with the precision of additive manufacturing.

Using 3D printing, custom-designed graphene-based structures can be fabricated for a variety of applications. This approach is particularly impactful in energy storage devices, such as batteries and supercapacitors, where graphene’s conductivity and large surface area significantly enhance performance.

The combination of graphene and 3D printing offers a new approach to manufacturing that differs from conventional techniques. This method allows precise control over material placement, enabling the creation of strong, lightweight structures.

These structures can also have optimized porosity and functionality, which are essential for improving energy density, charge-discharge rates, and overall efficiency.1

How is Graphene 3D Printed?

Techniques like fused deposition modeling (FDM) and stereolithography (SLA) are commonly used to 3D print graphene-based materials. These methods are well-suited for creating complex shapes with high precision.2

FDM works by depositing thermoplastic filaments embedded with graphene particles layer by layer to build intricate structures. This approach is often used to produce battery housings or thermal management components for power backup systems. The resulting parts are compact, durable, and offer improved mechanical strength and thermal conductivity, making them ideal for such applications.3

SLA, on the other hand, uses photopolymerization to cure resin mixed with graphene-based materials. A focused laser or ultraviolet light solidifies the resin layer by layer with exceptional accuracy, resulting in smooth and detailed structures. This technique is particularly effective for creating fine features and tailored electrode geometries, which are critical for improving the performance of batteries and supercapacitors.

SLA is also used to produce high-precision sensor enclosures, where its ability to create conductive and mechanically stable graphene components enhances the performance of electronic devices.4

A study published in Bioengineered highlighted that graphene-based electrodes, fabricated using advanced techniques, allow precise control over geometry and structure. This enables fine adjustments to properties like conductivity, surface area, and porosity.5

These characteristics are essential for optimizing energy storage capabilities, ensuring faster charge-discharge cycles, and extending device lifespans. By integrating graphene into 3D printing, researchers and manufacturers can develop energy storage systems tailored to specific performance requirements.5

Printing with Graphene to Create Electronics (UoM Chemistry 05 )

Application of 3D-Printed Graphene in Energy Systems

Renewable Energy Storage

3D-printed graphene supports efficient energy storage for solar and wind systems, helping to manage fluctuations in energy supply. 3D printing also facilitates the creation of custom designs, offering scalability and adaptability across diverse renewable energy setups.3

This technology minimizes material waste, reduces production costs, and supports environmentally sustainable energy solutions, making it well-suited for large-scale renewable applications.6

Hybrid Energy Systems

Graphene-based batteries and supercapacitors can be combined to meet the demands of applications requiring both high energy density and rapid energy delivery. 3D printing enhances these systems by enabling tailored electrode designs, ensuring efficient energy retention and faster charge-discharge cycles. Customization also allows hybrid systems to balance storage capacity and power delivery while maintaining material efficiency and scalability.7

Lithium-Ion Batteries

Graphene-enhanced lithium-ion batteries improve energy density and cycle life by enhancing electrode conductivity and structural stability. 3D printing allows precise control over electrode geometry, which optimizes ion transport pathways, leading to better energy retention and extended battery life. This approach reduces weight while maintaining robustness, making these batteries ideal for electric vehicles (EVs).8

Advances in 3D printing technology also support cost-effective manufacturing of these batteries, with less material waste compared to conventional methods, contributing to both economic and environmental sustainability.6

Sodium-Ion Batteries

The ability to 3D print custom electrodes for sodium-ion batteries optimizes charge capacity and cycling strength, ensuring efficient energy storage. Scalable production methods, combined with graphene’s adaptability, make these batteries a practical solution for sustainable energy needs.9

Supercapacitors

Supercapacitors benefit significantly from graphene’s ability to boost energy and power density while enabling rapid charge and discharge cycles. 3D-printed graphene structures further enhance surface area and porosity, which are critical for maximizing energy storage and delivery. The scalability of 3D printing supports the efficient production of customized designs for various applications, from portable devices to industrial systems.10-12

Flexible Energy Storage Devices

Graphene-based 3D printing supports the development of stretchable batteries designed for wearable electronics and portable devices. For example, it is used to create flexible batteries for fitness trackers, where mechanical flexibility and high energy efficiency are essential. These batteries are ideal for compact, adaptable applications.13

Understanding Graphene Batteries

Graphene in 3D Printing: Challenges and Future Opportunities

Despite its potential, 3D-printed graphene faces several challenges. High production costs, driven by the need for specialized equipment and high-quality graphene, make large-scale manufacturing difficult.

Additionally, material stability remains an issue, as graphene can degrade over time, affecting the performance and lifespan of energy storage devices. Ensuring consistent, scalable production of reliable graphene materials will require further research.13

Looking forward, advancements in material science and 3D printing are expected to improve production efficiency and reduce costs, making 3D-printed graphene more viable for commercial applications. The ability to customize electrode structures will continue to enhance energy density, charge-discharge rates, and overall device performance.

As methods improve, these technologies may also play a role in renewable energy storage, helping manage supply fluctuations more effectively. While challenges remain, 3D-printed graphene has the potential to contribute to practical, efficient, and sustainable energy storage solutions.

Reference and Further Reading

1.Wu, Y., An, C., Guo, Y. (2022). 3D Printed Graphene and Graphene/Polymer Composites for Multifunctional Applications. Materials. DOI: 10.3390/ma16165681, https://www.mdpi.com/1996-1944/16/16/5681

2. Nagaraju, DS., et al. (2023). Mechanical properties of 3D printed specimen using FDM (Fused deposition modelling) and SLA (Stereolithography) technologies. Materials Today: Proceedings. DOI: 10.1016/j.matpr.2023.09.223, https://www.sciencedirect.com/science/article/abs/pii/S2214785323049040

3.Pavlovskii, AA., et al. (2023). 3D-Printed Lithium-Ion Battery Electrodes: A Brief Review of Three Key Fabrication Techniques. Materials. DOI: 10.3390/ma17235904, https://www.mdpi.com/1996-1944/17/23/5904

4. Barreto, DN., et al. (2024). Fabrication of Low-Cost Miniaturized Gas Cells via SLA 3D-Printing for UV-Based Gas Sensors. ACS Omega. DOI: 10.1021/acsomega.3c09317, https://pubs.acs.org/doi/full/10.1021/acsomega.3c09317

5.Weerarathna, IN., et al. (2024). Engineering with Biomedical Sciences Changing the Horizon of Healthcare-A Review. Bioengineered, 15:1. DOI: 10.1080/21655979.2024.2401269, https://www.tandfonline.com/doi/abs/10.1080/21655979.2024.2401269

6. Yu, L.-H., et al. (2022). Recent development of three-dimension printed graphene oxide and MXene-based energy storage devices. Tungsten. DOI: 10.1007/s42864-022-00181-2, https://link.springer.com/article/10.1007/s42864-022-00181-2

7. Son, J., Kim, H., Choi, Y., Lee, H. (2024). 3D printed energy devices: generation, conversion, and storage. Microsystems & Nanoengineering. DOI: 10.1038/s41378-024-00708-2, https://www.nature.com/articles/s41378-024-00708-2

8. Liu, Z., et al. (2024). Exploring a preheating strategy for lithium-ion battery pack using graphene-enhanced microencapsulated phase change materials. Journal of Energy Storage. DOI: 10.1016/j.est.2024.114609, https://www.sciencedirect.com/science/article/pii/S2352152X24041951

9. Li, C., et al. (2023). Nonaqueous Liquid Electrolytes for Sodium‐Ion Batteries: Fundamentals, Progress and Perspectives. Advanced Energy Materials (Print). DOI:10.1002/aenm.202301758, https://onlinelibrary.wiley.com/doi/abs/10.1002/aenm.202301758

10. Yang, Z., et al. (2023). 3D printing of carbon tile-modulated well-interconnected hierarchically porous pseudocapacitive electrode. Energy Storage Materials. DOI: 10.1016/j.ensm.2022.10.025, https://www.sciencedirect.com/science/article/abs/pii/S2405829722005499

11. Mubarak, S., et al. (2023). Recent advances in 3D printed electrode materials for electrochemical energy storage devices. Journal of Energy Chemistry. DOI: 10.1016/j.jechem.2023.01.037, https://www.sciencedirect.com/science/article/abs/pii/S2095495623000530

12. Chang, Y., Cao, Q., Venton, B. Jill. (2023). 3D printing for customized carbon electrodes. Current Opinion in Electrochemistry. DOI: 10.1016/j.coelec.2023.101228, https://www.sciencedirect.com/science/article/abs/pii/S2451910323000212

13. Han, S.-C., et al. (2022). 3D printing of architectured graphene-based aerogels by cross-linking GO inks with adjustable viscoelasticity for energy storage devices. Rare Metals. DOI: 10.1007/s12598-022-02202-y, https://link.springer.com/article/10.1007/s12598-022-02202-y