Precious metals play an important role in the chemical industry as catalysts: With the help of silver, platinum, palladium or other elements, chemical reactions can take place that would otherwise not progress or would only progress at a much lower reaction rate. These metals are often used in the form of tiny nanoparticles.

However, how well they work also depends on the surface on which they are placed. Nanoparticles on a carbon base seem to work particularly well, but the reason for this was unknown for a long time.

At TU Wien, however, researchers for the first time precisely measured and explained the interaction between metal nanoparticles and a carbon substrate. Silver atoms on a carbon support were found to be 200 times more active than atoms in a piece of pure silver. The findings are published in the journal ACS Catalysis.

Computer simulations show that the zone in which the silver is in direct contact with the carbon is crucial. With the help of hydrogen isotope exchange, a method was developed to test catalyst supports for their effectiveness more quickly and easily.

From ‘black art’ to science

“For a long time, the use of carbon as a carrier material for catalysis had something almost magical,” says Prof. Günther Rupprechter from the Institute of Materials Chemistry at TU Wien. The University of Cádiz (Spain) and the Center for Electron Microscopy USTEM at TU Wien were also involved.

The source of carbon turned out to be important. For some processes, carbon is used that was obtained from coconut shells, fibers or special woods. Such “recipes” can even be found in patent documents—although the origin of chemical substances should actually be relatively irrelevant. “It always seemed a bit like black art,” says Rupprechter.

The idea was that different manufacturing methods could lead to minimal chemical or physical differences: Perhaps the carbon arranges itself in different ways depending on the method of manufacturing? Maybe it contains traces of other chemical elements? Or do functional groups accumulate on the surface—small molecular building blocks that intervene in the chemical reaction?

“In the chemical industry, people are naturally often content with the fact that a process works and can be repeated reliably,” says Rupprechter. “But we wanted to get to the origin of the effect and understand exactly what is actually going on here at the atomic level.”

Precision measurements in a microreactor

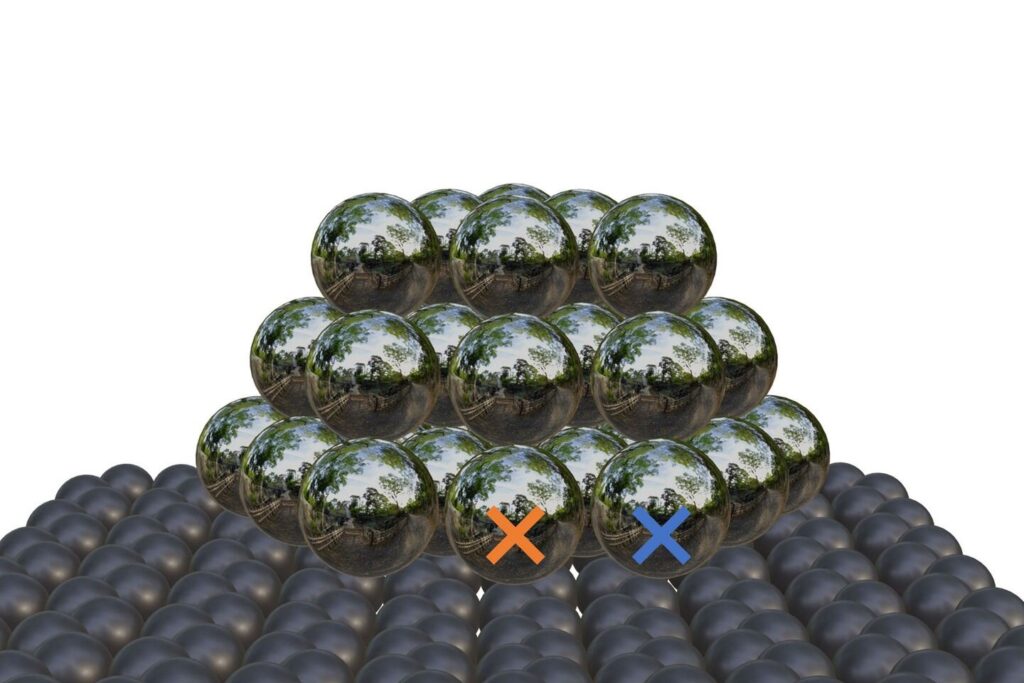

The team first produced samples that could be characterized extremely precisely: silver nanoparticles of a known size on a carbon substrate—and a thin silver foil without carbon.

Both samples were then examined in a chemical reactor. “Silver can be used to split hydrogen molecules into individual hydrogen atoms,” explains Thomas Wicht, the first author of the study. “This hydrogen can then be used, for example, for the hydrogenation reaction of ethene.

“In an analogous manner, one can also mix ‘ordinary’ hydrogen molecules with molecules made of heavy hydrogen (deuterium). Both molecules are then dissociated by the silver and recombined.”

The more active the catalyst, the more frequently the two hydrogen isotopes are exchanged. This provides very reliable information about the catalyst activity.

This meant that for the first time, the difference in activity between silver atoms with and without a carbon support could be precisely quantified—with spectacular results. “For each silver atom, the carbon background induces a 200 times higher activity,” says Wicht.

“This is, of course, very important for industrial applications. You only need a two-hundredth of the amount of expensive precious metals to achieve the same activity—and you can do that simply by adding comparatively inexpensive carbon.”

Discover the latest in science, tech, and space with over 100,000 subscribers who rely on Phys.org for daily insights.

Sign up for our free newsletter and get updates on breakthroughs,

innovations, and research that matter—daily or weekly.

The exciting effect happens right at the border

Alexander Genest from the TU Wien team carried out computer simulations comparing the activation of hydrogen by silver nanoparticles on carbon and pure silver. This made it clear: The boundary region between silver particles and carbon carrier is crucial. The catalyst effect is greatest exactly where the two come into contact.

“So it’s not the size of the carbon surface or any foreign atoms or functional groups. An extreme catalytic effect occurs when a reactant molecule comes into contact with both a carbon and a silver atom directly at the interface,” says Genest. The larger this area of direct contact, the greater the activity.

This knowledge means that different carbon batches from different sources can now be checked quite easily for their effectiveness. “Now that we have understood the mechanism of action, we know exactly what to pay attention to,” says Rupprechter.

“Our experiment, in which we expose the catalysts to a mixture of ordinary and heavy hydrogen, is relatively easy to carry out and provides very reliable information as to whether this variant of the carbon carrier is also suitable for other chemical reactions or not.”

Being able to explain processes at the atomic level should now save time and money in industrial use and simplify quality assurance.