In the early 20th century, the development of a catalyst for ammonia synthesis by the Haber-Bosch method took more than 10,000 experiments before it was successful. The development of new materials is a time-consuming and costly process from design to commercialization.

However, in recent years, researchers have been working to shorten the development period by using artificial intelligence (AI). When combined with robots, it is possible to conduct material development research 24 hours a day, 365 days a year without human intervention.

Dr. Sang Soo, Han and Dr. Donghun, Kim of the Computational Science Research Center and Professor Kwan-Young Lee of the Department of Chemical Engineering and Biotechnology at Korea University have developed a bespoke synthesis platform of nanomaterials using AI and robotics, called Smart Lab.

The research is published in the journal Advanced Functional Materials.

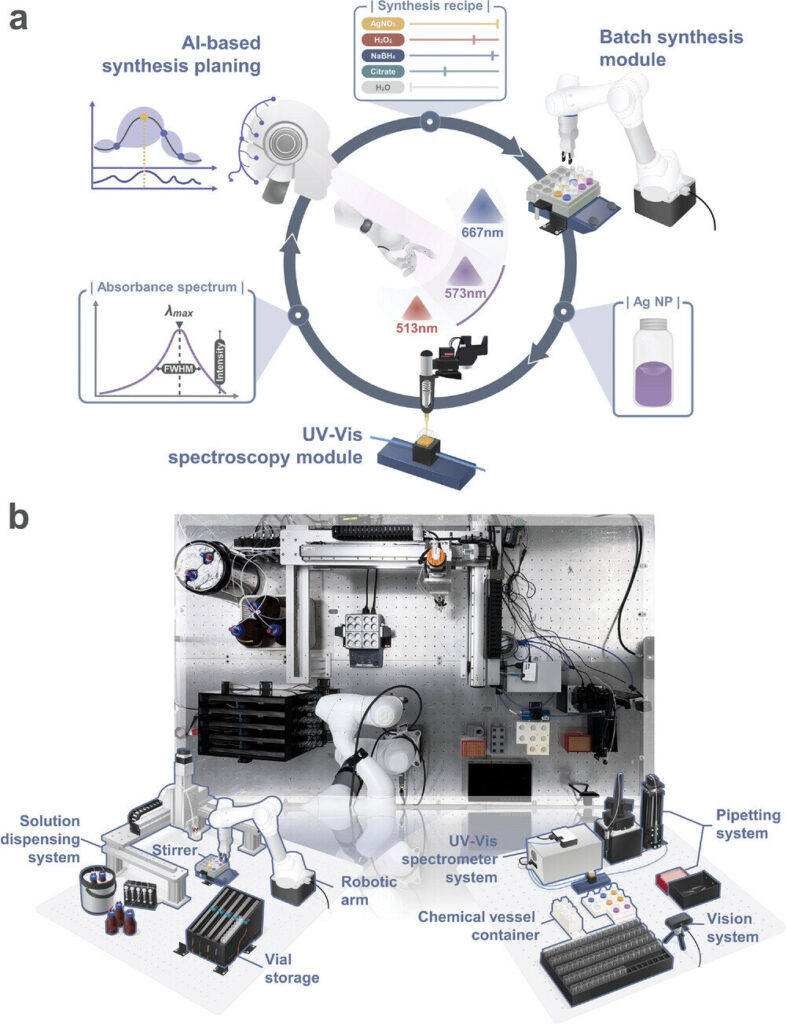

The Korea Institute of Science and Technology (KIST)-Korea University joint research team first developed an automated device that synthesizes nanoparticles based on a robotic arm and measures the optical properties of the synthesized nanoparticles. By combining AI technology with this, a smart laboratory for bespoke synthesis of nanomaterials was developed, with which researchers can readily synthesize nanomaterials that meet their requirements just by inputting the desired material properties.

The AI technology applied to the Smart Lab platform combines a Bayesian optimization method with the early stopping technology to increase the efficiency of material discovery by more than 500 times compared to simple automated devices.

Human experiments are often difficult to obtain reproducible results because the results are very sensitively dependent on the research environment and the proficiency of researchers; however, the developed smart lab has the advantage of producing consistent, high-quality data in large quantities.

The researchers also developed an AI technology to ensure the safety of smart labs. Although there is no risk of injury to researchers in unmanned smart labs, it is difficult to prevent safety accidents such as malfunctions due to robot overload.

The researchers developed an AI vision technology (DenseSSD) to detect and prevent such safety accidents in advance and installed it in the smart lab. DenseSSD detects various objects in the lab, including research equipment and materials, and notifies users of any abnormalities so that they can take appropriate measures.

“The smart lab platform, which enables material development without human intervention, will be a new R&D paradigm that can solve the problem of declining research manpower due to aging,” said Dr. Sang Soo, Han of KIST.

“In the future, we plan to incorporate interactive language models such as ChatGPT to make it easier for non-experts to use the smart lab,” said Dr. Donghun, Kim. The research team plans to expand the Smart Lab platform to various material fields such as catalysts, batteries, and displays.