Researchers have achieved a significant breakthrough in the synthesis of carbon nanotubes (CNTs) by developing a novel catalyst that allows for precise control over their atomic arrangement, known as chirality. This advancement paves the way for the creation of innovative semiconductor devices, addressing a challenge that has remained unresolved for over 30 years.

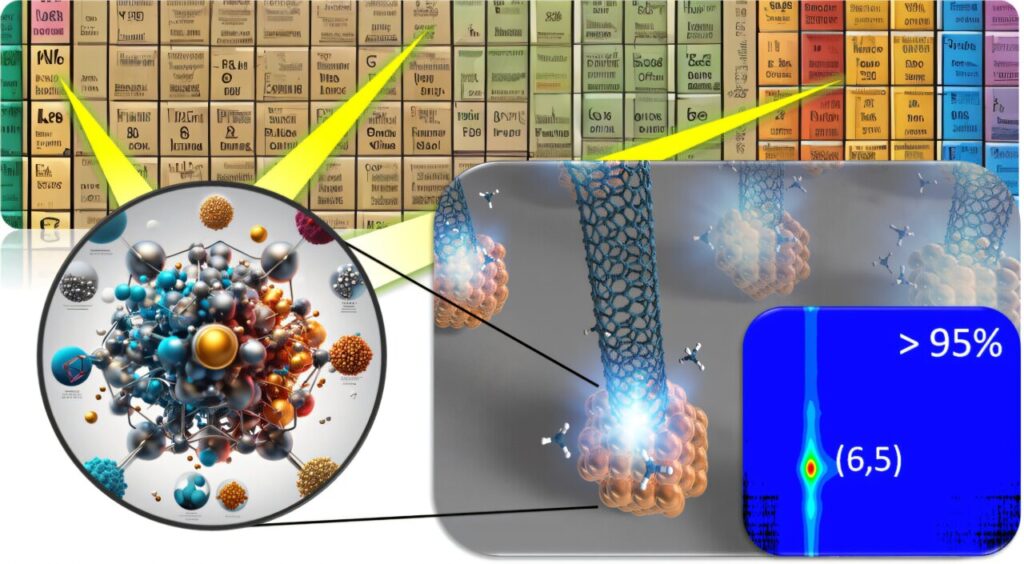

The team consisting of researchers across Japan, led by Associate Professor Toshiaki Kato from the Advanced Institute for Materials Research (WPI-AIMR), has successfully synthesized CNTs with a chiral index of (6,5) at an ultra-high purity of over 95%.

These findings were published in ACS Nano on August 20, 2024.

“A carbon nanotube is basically a sheet of carbon rolled into a hollow tube,” explains Kato, “While it sounds simple, CNTs are highly sought after for properties such as their exceptional conductivity, optical characteristics, and mechanical strength.”

It’s no wonder they’re nicknamed the “king of nanomaterials.” This laundry list of desirable traits makes them a promising option for a truly broad number of applications—from constructing aircraft and spaceships to developing biomedical devices.

“The inability to control CNT chirality has been a major barrier to their industrial application, so this project was undertaken to find a catalyst that could consistently produce the desired target,” says Kato. Thus far, single-chirality synthesis with a purity of over 90% has only been achieved for (14,4) and (12,6) chiralities.

By introducing a new catalyst composed of nickel (Ni), tin (Sn), and iron (Fe), the researchers have opened a new pathway for chirality-controlled synthesis. This NiSnFe catalyst acts as a highly specialized growth catalyst, enabling the selective synthesis of (6,5) chirality CNTs.

Furthermore, these chirality-pure bundle structures of (6,5) CNTs show more than a 20-fold increase in their photoluminescence lifetime, compared to isolated (6,5) CNTs. This technique could potentially be used in the future to achieve other chiralities as well.

The research team anticipates that their findings will lead to significant advancements in how semiconductor devices are manufactured and used.