Organic thermoelectric materials hold great promise as flexible energy sources for the Internet of Things and wearable electronics. However, their relatively low dimensionless figure of merit (ZT) compared to traditional materials has been a major obstacle, limiting their use in thermoelectric power generation and solid-state cooling.

Prof. Di Chong’an from the Institute of Chemistry of the Chinese Academy of Sciences and Prof. Zhao Lidong from Beihang University, along with their collaborators, have introduced a polymeric multi-heterojunction (PMHJ) structure that achieved a ZT exceeding 1.0. The study was published in Nature.

Ideal thermoelectric materials should conform to the “phonon-glass electron-crystal” model. Currently, enhancing the power factor is the primary focus in developing high-performance organic thermoelectric materials. Despite efforts to improve thermoelectric efficiency by assessing thermal conductivity, the lack of effective strategies for phonon scattering in soft material systems has impeded significant progress in achieving a leap in the ZT value over the past decade.

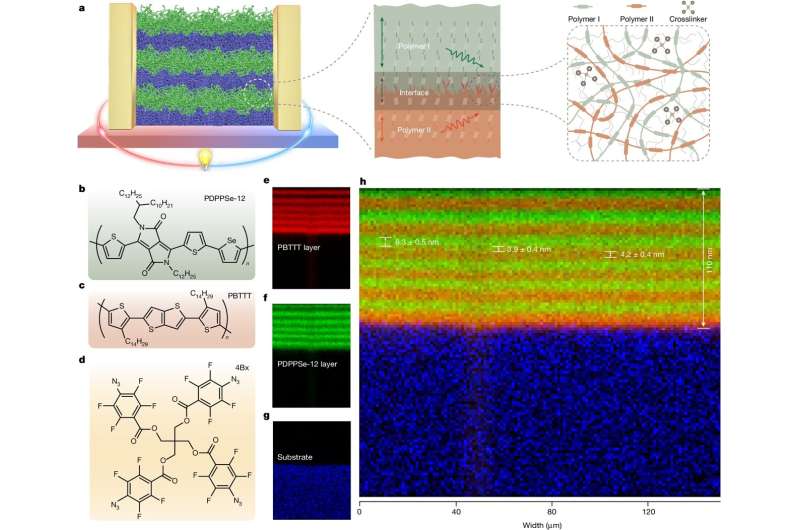

In this study, the researchers proposed the PMHJ structure to manipulate thermal conductivity in organic systems. This novel design features a periodically arranged nanostructure, with each polymer layer measuring less than 10 nm thick. The adjacent interface layers are approximately two molecular layers thick and exhibit bulk heterojunction properties.

By precisely controlling the polymer layer thickness and interfacial structural characteristics, the researchers studied the size effect and diffuse scattering of phonon/phonon-like thermal vibrations within the PMHJ structure.

They discovered that as the layer thickness approached the phonon mean free path along the conjugated backbone direction, interface scattering intensified, leading to a significant reduction in the film’s lattice thermal conductivity by more than 70% to 0.1 W m-1 K-1. Furthermore, they discovered that the doped (6,4,4) film demonstrated excellent electrical transport properties, with a high power factor of 628 μW m-1 K-2 and a maximum ZT of 1.28, far surpassing current organic thermoelectric materials.

Besides these achievements, PMHJ films are compatible with large-area solution processing technology. The thermoelectric integrated devices exhibited an impressive normalized power density of 1.12 μW cm-2 K-2, highlighting their potential for use in flexible power supply components.

This study underscores the importance of nanostructure engineering in overcoming the limitation of weakly interacting plastics due to low ZT. It offers a new way of making advancements in plastic-based thermoelectric materials.