Nanostructured high entropy alloys—metals made from a chaotic mix of several different elements—show a lot of promise for use in industries such as aerospace and automotive because of their strength and stability at high temperatures compared with regular metals.

But they are expensive and energy-intensive to produce. Now, researchers working with the Canadian Light Source (CLS) at the University of Saskatchewan (USask) have found a much cheaper and easier way to make them, opening the door for commercial applications.

Michel Haché, a materials engineer at the University of Toronto, and colleagues confirmed that electrodeposition is a cost-effective and easily scaled way to create these alloys. Electrodeposition—which involves dissolving metal ions in water and then using an electric current to pull them out of the liquid and form solid materials—is the same process that is used to make chrome-plated motorcycle parts. The findings are published in the journal Surface and Coatings Technology.

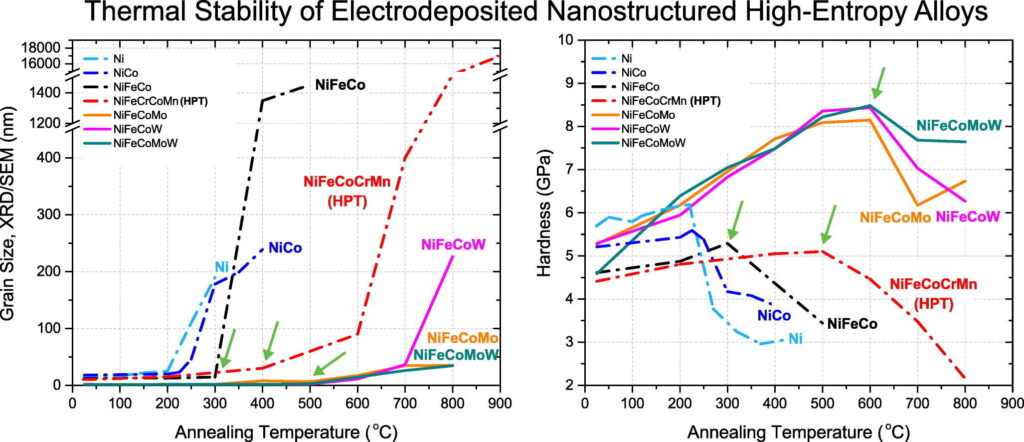

The U of T group found that alloys made of several different metals—nickel, iron, cobalt, tungsten, and molybdenum—could withstand temperatures up to 500°C, compared with just 270°C for pure nickel, and were stronger and harder than their less-complex counterparts. “We’re using chaos in the material structure to bring out interesting properties,” he says.

And they found that the more chaos they added to an alloy, the better it got—up to a point. Alloys made with four different elements could withstand temperatures 100°C higher than those made with just three, but adding a fifth element led to no further improvements.

That’s an extra bonus, says Haché, because it is easier and cheaper to work with fewer elements. “It allows us to be more efficient when we look for new applications,” he says.

These alloys could be useful for making tools or parts for applications where temperatures and mechanical stresses can be extremely high, such as in the automotive and aerospace industries, says Haché. “Anywhere that we are trying to push materials to their absolute limits,” he says.