Shanghai Jiao Tong University (SJTU) researchers have developed a highly sensitive and reusable surface-enhanced Raman spectroscopy (SERS) microfluidics system that has achieved a detection limit lower than 10 ppt (parts per trillion) of harmful substances.

The work, reported in the International Journal of Extreme Manufacturing, could broaden the applications of ultrasensitive, effective, and low-cost microfluidic detection in biomedical diagnosis, environmental monitoring, and food safety.

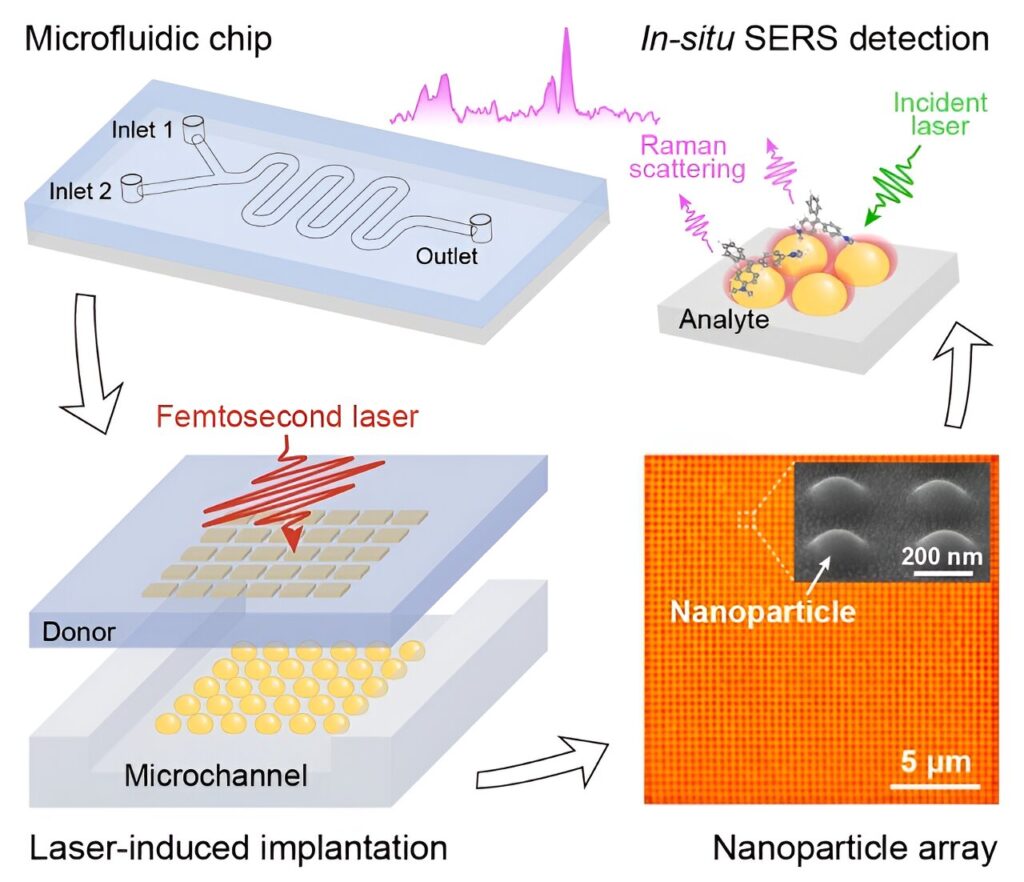

Integrating plasmonic nanoparticles into microfluidic chips with high accuracy and stability is the basis of highly sensitive and reusable sensing.

“How to assemble well-designed nanoparticles into microchannels is a critical problem,” said Dr. Yongxiang Hu, first author of the paper and professor at SJTU’s School of Mechanical Engineering.

“In most research, the SERS-active substrate is fabricated separately in advance and then integrated with microfluidic chips, suffering from low fabrication efficiency and expensive costs. We need to find a fast and affordable technique. Here we are saying, why not implant nanoparticles into the microchannel directly?”

In recent years, direct femtosecond laser structuring has been used to develop many high-sensitive microfluidic SERS systems, offering various flexible SERS-active interface fabrication routes.

Nanoparticles can be synthesized in microchannels for SERS detection with resolution as low as 10-10 mol/L using laser-induced photoreduction. However, laser-reduced nanoparticles are susceptible to oxidization when exposed to air, which will affect their service lifetime. Moreover, the laser-fabricated structures are challenging to control in a uniform manner, limiting the improvement of sensitivity and reproducibility.

Using femtosecond laser-induced forward transfer (fs-LIFT) technology, the researchers implanted the nanoparticle in a square lattice with a uniform pitch of about 400 nm, achieving a mean deviation of only 3%. A remarkable electromagnetic field enhancement resulted in a detection limit lower than 10-11 mol/L. Furthermore, the fabricated array shows excellent reusability after several physical and chemical cleanings, because of the robust embedment of fs-LIFT-implanted nanoparticles.

Thanks to the high stability and sensitivity, the researchers used this method to fabricate a SERS microfluidic system and monitor the online oxidation reaction, which helps them infer the reaction path.

The researchers are continuing the work, hoping to improve the sensitivity further by reducing the particle size and arrangement pitch. They expect the technology to be used in biomedical detection for disease screening and diagnosis applications in the future.

Provided by

International Journal of Extreme Manufacturing