The heterogeneous photocatalysis (HPC) based Advanced Oxidation Process (AOP) is an eco-friendly technique for purifying water from organic and biological pollutants in environmental systems. The photocatalysts’ overall catalytic performance usually depends on light harvesting, photogenerated charge carrier separation and transfer, and surface reactivity.

There are numerous research works trying to explore the benefits of HPC for water treatment, but their practical implementation is restricted for various reasons. These include low efficiencies, complicated photoreactor designs, high operation and synthesis costs, photocatalyst poisoning, and fast electron-hole recombination.

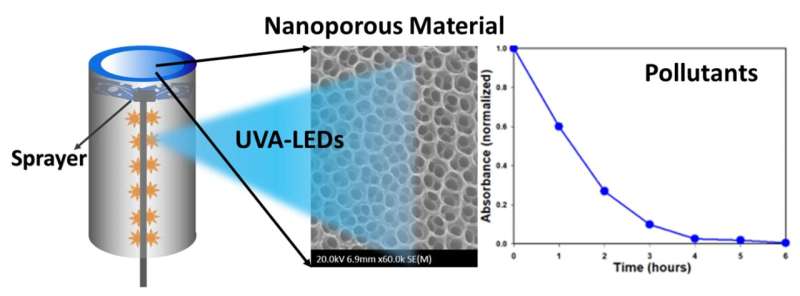

To overcome these issues, a collaboration between academia and industrial partners has evaluated a system where highly organized nanoporous photocatalyst material is employed synergistically with highly efficient UVA LEDs, thin water film and water scrubbing. Their work was published in the journal Industrial Chemistry & Materials.

“The goal is to finally have a photocatalytic reactor that is energy efficient, simple in design and easy to scale up based on the application,” explains John B Hayden of Waterdrape LLC (inventor), Even after decades of research and thousands of published research articles, there is still a massive gap between promising research work and the industrialization of technology.

Most photocatalytic reactors use nanopowder materials which have inherent limitations. On a lab scale, it is easy to centrifuge the nanomaterial powder after the photocatalytic oxidation of the pollutant. However, on a large scale where thousands of liters of water need to be treated, it becomes challenging to dispense that much powder-based photocatalyst in the water and then make sure all of it is filtered out before discarding the treated water back in the environment.

These slurry-based photocatalytic reactors are typically energy inefficient and prone to catalyst fouling or photo-aggregation. We employed an immobilized photocatalyst grown directly on a titanium substrate, eliminating the need for ultrafiltration and providing mechanical stability to the photocatalyst.

Thin water films and water scrubbing kept the photoreactor saturated with oxygen thus reducing electron-hole recombination. The photoreactor was tested for real-world application such as cleaning hot tubs without chemicals.

A two-month-long experiment was conducted on a heavily used hot tub with a water volume of 1200 L without added chlorine, bromine, ozone, etc. No increase in the Total Organic Compound (TOC) and Chemical Oxygen Demand (COD) was measured, showing that the photocatalytic reactor was able to completely oxidize the organic and biological entities entering the water.

Looking ahead, the company and the researchers hope that their work will further help in the advancement of environmentally friendly technologies for water treatment applications. The simple design and scalability of the photoreactor accompanied by highly stable, energy-efficient, and long-lasting UVA LEDs provide a technology ready to achieve its ultimate goal of industrial applications.

The team is performing research on enhancing the performance of the technology that proves effective in various water conditions mainly focusing on the ionic interference in the saline environment. They are also exploring the prospect of using this further improved advanced oxidation process (AOP) technology towards the destruction of PFAS (forever chemicals).

Provided by

Industrial Chemistry & Materials