In a leap toward more powerful and efficient computer chips, researchers at the University of Virginia have confirmed a key principle governing heat flow in thin metal films—a critical component in the race to design faster, smaller and more efficient devices.

This work, published in Nature Communications, offers a breakthrough in understanding how thermal conductivity works in metals used within next-generation chips, unlocking possibilities for advancements in technology at scales once thought unattainable.

“As devices continue to shrink, the importance of managing heat becomes paramount,” said lead researcher and mechanical and aerospace engineering Ph.D. student Md. Rafiqul Islam. “Consider high-end gaming consoles or AI-driven data centers, where constant, high-power processing often leads to thermal bottlenecks. Our findings provide a blueprint to mitigate these issues by refining the way heat flows through ultra-thin metals like copper.”

Heat at the nanoscale

Copper, widely used for its excellent conductive properties, faces significant challenges as devices scale down to nanometer dimensions. At such small scales, even the best materials experience a drop in performance due to increased heat—a phenomenon that’s amplified in copper, leading to lower conductivity and efficiency.

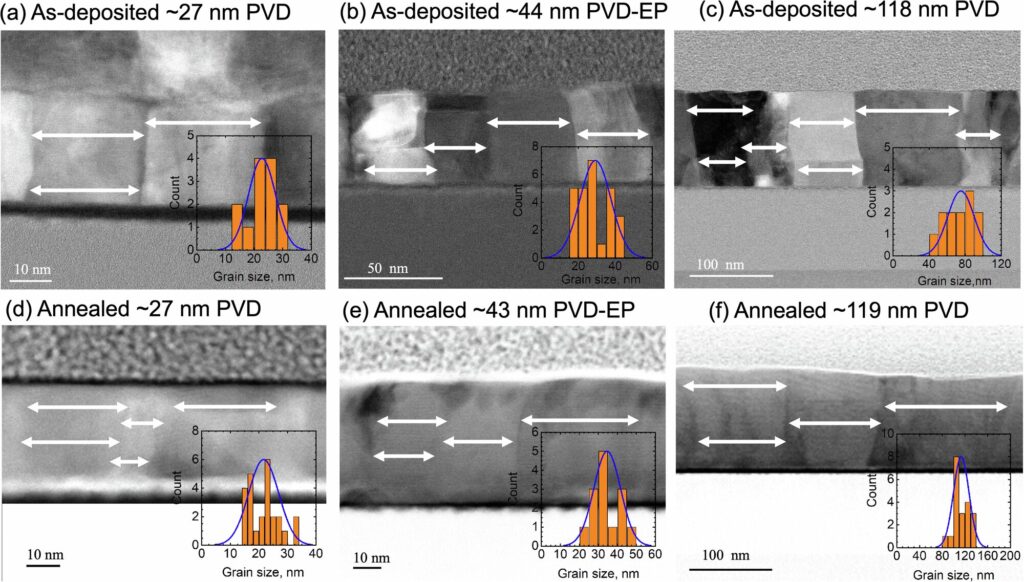

To address this, the UVA team focused on a crucial element of thermal science known as Matthiessen’s rule, which they validated in ultra-thin copper films. The rule, which traditionally helps predict how different scattering processes influence electron flow, had never been thoroughly confirmed in nanoscale materials until now.

Using a novel method known as steady-state thermoreflectance (SSTR), the team measured copper’s thermal conductivity and cross-checked it with electrical resistivity data. This direct comparison demonstrated that Matthiessen’s rule, when applied with specific parameters, reliably describes the way heat moves through copper films even at nanoscale thicknesses.

Cooler, faster and smaller chips

Why does this matter? In the world of very-large-scale integration (VLSI) technology, where circuits are packed into incredibly tight spaces, effective heat management directly translates to improved performance. This research not only points to a future where our devices run cooler but also promises a reduction in the amount of energy lost to heat—a pressing concern for sustainable technology.

By confirming that Matthiessen’s rule holds even at nanoscale dimensions, the team has paved the way for refining materials that interconnect circuits in advanced computer chips, setting a standard for material behavior that manufacturers can rely on.

“Think of it as a roadmap,” said Patrick E. Hopkins, Isam’s adviser and the Whitney Stone Professor of Engineering. “With the validation of this rule, chip designers now have a trusted guide to predict and control how heat will behave in tiny copper films. This is a game-changer for making chips that meet the energy and performance demands of future technologies.”

A collaboration for the future of electronics

The success of this study represents a collaboration between UVA, Intel and the Semiconductor Research Corporation, highlighting the strength of academic-industry partnerships. The findings promise significant applications in the development of next-generation CMOS technology—the backbone of modern electronics. CMOS, or complementary metal-oxide-semiconductor, is the standard technology for building integrated circuits that run everything from computers and phones to automotive and medical devices.

By combining experimental insights with advanced modeling, UVA researchers have opened a door to materials that not only drive more efficient devices but also hold the potential for impactful energy savings across the industry. In a field where every degree of temperature control counts, these insights mark a vital step forward for the electronics industry, making a future of cooler, faster and more sustainable devices more achievable than ever.