Atomic force microscopy has long relied on the ability to acquire nanoscale chemical information while simultaneously characterizing nanomechanical properties. This article explores a new means of achieving this goal, introducing a method that combines two established methods: Resonance-Enhanced photothermal AFM-IR and force volume imaging.

The article will outline and discuss the best approach to implementing and operating this novel photothermal AFM-IR method and provide several application examples.

This technique offers an accessible, accurate, easy-to-use approach to performing combined quantitative chemical and mechanical characterization.

Technological Background

Nanoscale infrared (nanoIR) microscopy facilitates label-free chemical imaging and spectroscopy at the nanometer scale by leveraging a combination of atomic force microscopy (AFM) and infrared radiation.

In recent years, AFM-IR has been developed to accommodate a range of AFM operational modes.

For example, Resonance-Enhanced AFM-IR mode and the newer surface-sensitive AFM-IR technique are based on contact mode, while Tapping AFM-IR is based on tapping mode.1 PeakForce Tapping®–based PeakForce infrared (PFIR) microscopy represents another more recent AFM-IR mode.2

Each nanoIR variation benefits from the advantages of its respective AFM base mode while also being subject to its limitations.

Resonance-Enhanced Force Volume (REFV) AFM-IR is a novel force volume–related approach. This method leverages the power of adjustable hold (dwell) time functionality, performing resonance-enhanced AFM-IR imaging or spectroscopy within this window.

REFV AFM-IR can perform simultaneous multimodal imaging, acquiring chemical information and mechanical properties such as elastic modulus and adhesion together (Figure 1).

Figure 1. Simultaneous multimodal imaging (height, adhesion, and IR absorption) enabled by REFV AFM-IR. Image Credit: Bruker Nano Surfaces and Metrology

REFV AFM-IR offers its users:

- The ability to measure soft, sticky, fragile, or otherwise challenging samples with <10 nm spatial resolution and monolayer detection sensitivity, achieved by eliminating lateral forces.

- The capacity to acquire nanomechanical and nanochemical measurements simultaneously.

- New, easy-to-use capabilities for artifact-free imaging and spectroscopy. These include decoupling mechanical property variations from AFM-IR data by employing a frequency sweep during the dwell time or via a more conventional phase-locked loop (PLL).

- The ability to simultaneously extract contact resonance data to provide large datasets with comprehensive sample information in a single scan.

Working Principles

Resonance Enhanced AFM-IR

IR signal detection in REFV AFM-IR leverages the underlying sensing concept of resonance-enhanced AFM-IR. Bruker’s patented resonance-enhanced AFM-IR mode sees the AFM cantilever being held on the sample in contact mode, with the laser pulse repetition rate specifically tuned to match the cantilever’s contact resonance frequency.

Thermal expansion occurs due to the sample’s absorption of infrared radiation, resulting in continuous cantilever excitation.

It is then possible to acquire a resonance-enhanced AFM-IR spectrum by plotting the amplitude of a chosen cantilever resonance in the frequency domain as a function of the laser wavelength.

A higher cantilever eigenmode (>1 MHz) offers higher spatial resolution and a smaller probing depth due to the shorter thermal diffusion length. This is the case in both spectroscopy and imaging applications.

Resonance-enhanced detection offers exceptionally high sensitivity because the AFM cantilever oscillation is enhanced at resonant excitation. This allows AFM-IR measurements to be performed on even thin samples, like self-assembled monolayers.

Resonance-enhanced AFM-IR’s spatial resonance resolution can extend down to 20 nm for relatively smooth samples.3 A phase-locked loop (PLL) is typically implemented to compensate for the mechanical difference between the sample’s different components.

This works by maintaining the match between the laser pulse rate and the local contact resonance frequency of the cantilever on the sample, avoiding the risk of inducing artifacts via mechanical variations of mechanical properties.3,4

Force Volume Imaging

The force felt by the tip as it approaches and retracts from a point on the sample surface is recorded by acquiring a simple force curve with an AFM.

Force curves collated from an array of x-y points are combined into a three-dimensional array, or ‘volume,’ of position-dependent force data (force volume). It is possible to use this volume to extract quantitative nanomechanical properties in real time for each sample location, for example, stiffness, adhesion, or elastic modulus.

It is possible to achieve force ramp rates up to 300 Hz (FASTForce Volume™, FFV) by employing Bruker’s proprietary low-force trigger capability alongside a relative force setpoint measured against the probe deflection when not yet contacting the sample. This approach eliminates the deflection drifts typically found when using the absolute trigger of contact mode.

Complementary spectral information can be extracted by inserting a dwell or hold segment into each approach-retract cycle. For example, advanced quantitative nanomechanical methods such as AFM-nDMA (nanoscale dynamic mechanical analysis) and the FFV CR mode (contact resonance mapping) make use of a short dwell segment, computing viscoelastic properties from a force modulation spectrum or contact resonance spectrum, respectively.5,6

The DataCube hyperspectral electrical modes represent a further useful example. This approach involves ramping the sample voltage to extract an electrical spectrum (for example, I-V curves in DataCube TUNA or C-V ones in DataCube SCM).7

How REFV AFM-IR Works

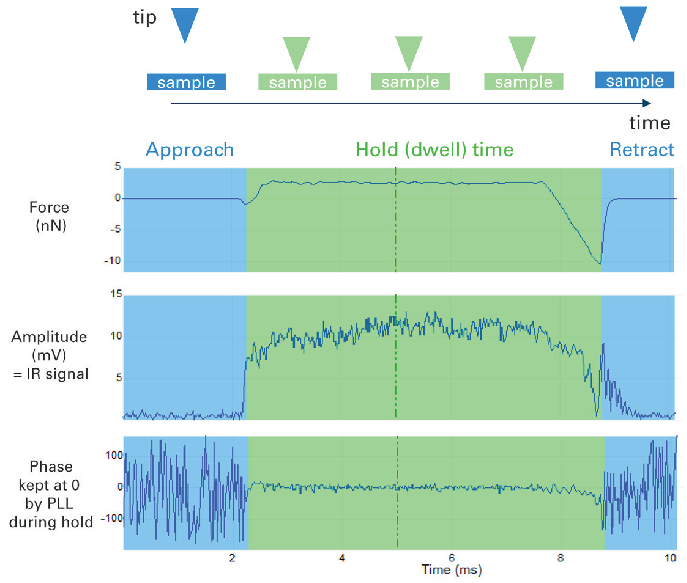

In REFV AFM-IR, resonance-enhanced detection is used to perform an AFM-IR measurement during the force volume dwell time. Figure 2 highlights the underlying principle of REFV AFM-IR in a single image pixel, illustrating the approach, dwell (5 ms in this instance), and retract segments.

This method leverages the inherent benefits of the contact mode-based resonance-enhanced AFM-IR mode while overcoming the contact mode’s limitations. For example:

- No lateral force is present during imaging and IR data collection. This lack of lateral force results in a longer tip lifetime and less risk of mechanically induced artifacts while offering the ability to successfully image fragile or soft samples.

- Force measurement becomes a relative measurement as opposed to an absolute measurement, avoiding any potential impact of deflection drift.

- It is possible to adjust dwell time duration to optimize the signal-to-noise ratio. The PLL feature remains available during these adjustments.

- Users can select a cantilever to meet their IR sensitivity and depth sensitivity needs, as well as better accommodate the sample’s elastic modulus range extracted via force curves.

Figure 2. Schematic implementation of REFV AFM-IR, illustrated for a single force volume cycle. The blue outer panels show the approach and retract of the cantilever to and from the sample surface, respectively, with the tip contacting the surface during a user-adjustable hold segment (here 5 ms, green). The middle and bottom spectra respectively show the amplitude (IR absorption) and phase (kept at zero by a PLL) from the resonance-enhanced AFM-IR measurement during the dwell time. Image Credit: Bruker Nano Surfaces and Metrology

A frequency sweep can be applied as an alternative to a fixed infrared laser pulse frequency (with or without PLL). It is possible to collect the contact resonance spectrum in full by performing a frequency sweep around one of the cantilever contact resonance eigenmodes, offering users a useful alternative to the PLL operation while ensuring that the IR resonance is acquired at the actual contact resonance.

Tracking the actual contact resonance removes the impact of frequency shifts induced by variations in the sample’s mechanical properties or topography.

Acquiring AFM-IR data during the approach and retract cycle is also possible. The example provided in Figure 2 highlights that some IR absorption remains during pull-off. This phenomenon is particularly relevant for studying IR absorption during ‘molecule pulling experiments.’

Integration in the MIROview™ GUI allows the user to effortlessly switch between regular resonance-enhanced AFM-IR and REFV AFM-IR imaging, as well as AFM-IR spectroscopy. This is especially important from a usability perspective.

During spectra acquisition, the typically several milliseconds short hold time leveraged in REFV AFM-IR imaging is extended to seconds until the IR wavelength sweep is completed.

Application Examples

The following case studies highlight select functionalities of REFV AFM-IR. Measurements are acquired using either a fixed laser pulse rate or with a frequency sweep of laser pulse rate.

Case Study Type 1: Dwell Time with Fixed Laser Pulse Rate

Figure 3 displays REFV AFM-IR imaging data acquired from a diluted PS-b-PMMA block copolymer sample. This data features correlated nanoscale chemical and mechanical characterization.

In the example presented here, a gold-coated cantilever with a spring constant of 0.2 n/m was ramped at a rate of 98 Hz and with a ramp size of 140 nm. Using this approach, a 140×256-pixel image was acquired within 11 minutes.

The laser was tuned to the probe’s higher-order contact resonance (approximately 1745 kHz), and an active PLL was employed to compensate for any contact resonance frequency shift during scanning. Therefore, resonance-enhanced IR data could be acquired during the 5 ms long hold segment of the force curve.

Figure 3. Diluted PS-b-PMMA core shell sample (with a 0.2 N/m probe) height, adhesion, and IR absorption, demonstrating spatial resolution of <10 nm with REFV AFM-IR. Image Credit: Bruker Nano Surfaces and Metrology

The height sensor image displayed in Figure 3 highlights the assembly of several smaller nanoparticle-like objects, while the concurrently obtained adhesion data shows an adhesion contrast between the surrounding shell and the nanoparticle core.

Due to the presence of IR absorption at the 1730 cm-1 carbonyl resonance, the shell could be uniquely identified as the PMMA component of the block copolymer. Therefore, the dark domain areas inside the assembly are PS rather than PMMA.

The IR-active material’s spatial distribution indicates an accumulation of PMMA in the shell of the nanoparticles, suggesting that these nanoparticles comprise a PS core covered by a PMMA shell. Spatial resolution in the IR response was noted to be <10 nm.

A further example employed a fixed laser pulse rate along a cantilever with higher stiffness of 40 n/m to match the sample’s modulus range. In this case, the sample under investigation was a polystyrene (PS) / low-density polyethylene (LDPE) blend with modulus values of ~2 GPa and ~100 MPa, respectively.

Figure 4 features simultaneously acquired quantitative modulus and adhesion maps with the IR absorption at 1493 cm-1, one of PS’s characteristic absorption bands.

Figure 4. REFV AFM-IR on a PS-LDPE blend with a stiff cantilever (~40 N/m) illustrating simultaneous IR imaging and quantitative nanomechanical property mapping (at the characteristic 1493 cm-1 band for the PS matrix). Image Credit: Bruker Nano Surfaces and Metrology

A different REFV AFM-IR example perfected with fixed laser pulse rate successfully illustrates the approach’s potential for monolayer sensitivity.

Figure 5 features results acquired from a 7 nm thin purple membrane sample. These results highlight simultaneous nanomechanical property mapping and IR imaging with monolayer sensitivity at the characteristic 1660 cm-1 amide I band.

Figure 5 also illustrates spectroscopic capability, with a 0.5 n/m probe used to acquire a 128×128 pixel image within three minutes.

Figure 5. REFV AFM-IR on a 7 nm thin purple membrane sample illustrating simultaneous IR imaging and quantitative nanomechanical property mapping, monolayer sensitivity in IR imaging (at the characteristic 1660 cm-1 amide I band) and spectroscopy. Image Credit: Bruker Nano Surfaces and Metrology

Case Study Type 2: Dwell Time with Frequency Sweep of Laser Pulse Rate

Figure 6 highlights the method’s ability to perform frequency sweeps during the REFV AFM-IR hold segment. The example presented here was done on a PMMA substrate with small tetrahydrofuran (THF) drops.

In this instance, the force ramp rate was close to 200 Hz, with a frequency sweep performed from 1090 to 1170 kHz at 1740 cm-1, corresponding to the PMMA carbonyl absorption band. This was done by covering one of the cantilever contact resonance eigenmodes during a 15 ms hold segment. The total acquisition time for the resulting 128×128 pixel image was approximately five minutes.

Figure 6. PMMA sample with THF droplets, showcasing atifact-free imaging with REFV AFM-IR when using laser pulse frequency sweeps over the local CR in each pixel (bottom left). In contrast, mechanically induced edge artifacts occur when imaging at a fixed laser repetition rate (bottom right). Sample courtesy of Philippe Leclère, University of Mons, Mons, Belgium. Image Credit: Bruker Nano Surfaces and Metrology

Figure 7 shows contact resonance spectra from the laser pulse frequency sweeps for two positions: one on top of a THF droplet (red marker) and one on the PMMA substrate (blue marker). These spectra show a notable shift in contact resonance frequency, further highlighting the importance of using a PLL or collecting the full frequency spectrum and then using a fit to extract the amplitude at resonance.

Figure 7. PMMA sample with THF droplets. IR absorption maps from Figure 6 included to show data location. Center plot is CR spectra from the PMMA (blue) and THF (red). Heat map on the right gives the evolution of local CR as measured in the IR absorption across the line. Sample courtesy of Philippe Leclère, University of Mons, Mons, Belgium. Image Credit: Bruker Nano Surfaces and Metrology

The amplitude image at the contact resonance (CR) was noted to be artifact-free (Figures 6 and 7), while the absorption image at fixed frequency included artifacts in the form of rings around the THF droplets. These were likely induced by variations in the sample’s mechanical properties.

Figure 7 displays IR amplitude versus frequency behavior for all pixels along the dashed line, highlighting the DataCube measurements’ high data content.

Powerful New Nanochemical Capabilities

Leveraging the power of the new Resonance Enhanced Force Volume AFM-IR mode affords its users more unique nanochemical research possibilities, ranging from multiplexed, exhaustive datasets for advanced users to novice-friendly mechanical tracking and utility on historically challenging samples.

REFV AFM-IR combines the industry-leading sensitivity afforded by Bruker’s patented resonance-enhanced AFM-IR mode for nanochemical analysis with a powerful force volume-based approach. This robust combination confidently expands sample compatibility and measurement capabilities across many applications, irrespective of the user’s previous experience with photothermal AFM-IR technology.

References and Further Reading

- Mathurin, J. et al. (2022). Photothermal AFM-IR spectroscopy and imaging: Status, challenges, and trends, Journal of Applied Physics, 131(1). https://doi.org/10.1063/5.0063902.

- Wang, L., Wang, H. and Xu, X.G. (2022). Principle and applications of peak force infrared microscopy, Chemical Society Reviews, 51(13), pp. 5268–5286. https://doi.org/10.1039/d2cs00096b.

- Bruker TN201 A Comprehensive Guide to Photothermal AFM-IR Spectroscopy. Available at: https://www.bruker.com/en/products-and-solutions/infrared-and-raman/nanoscale-infrared-spectrometers/resource-library/tn-201-a-comprehensive-guide-to-photothermal-afm-ir-spectroscopy.html.

- Bruker High-Performance Nanoscale IR Spectroscopy and Imaging with Dimension IconIR. Available at: https://www.bruker.com/en/products-and-solutions/infrared-and-raman/nanoscale-infrared-spectrometers/resource-library/an-206-high-performance-nanoscale-ir-spectroscopy-and-imaging-with-dimension-iconir.html.

- Pittenger, B. and Yablon, D.G. (2017). Quantitative Measurements of Elastic and Viscoelastic Properties with FASTForce Volume CR. [online] https://doi.org/10.13140/RG.2.2.25339.00806.

- Bruker App Note: Measuring Nanoscale Viscoelastic Properties with AFM-Based Nanoscale DMA. Available at: https://www.bruker.com/en/landingpages/bns/AFM-nDMA-atomic-force-microscopy-applications-pdf-download.html.

- Bruker Performing Hyperspectral Mapping with AFM DataCube Nanoelectrical Modes: Moving Beyond Property Mapping. Available at: https://www.bruker-nano.jp/library/57e489500c201abd043451c7/650edda1934b4522b0bdd0c4.pdf.

Acknowledgments

Produced from materials originally authored by Peter De Wolf, Ph.D., Martin Wagner, Ph.D., Qichi Hu, Ph.D., and Chunzeng Li, Ph.D., from Bruker.

This information has been sourced, reviewed and adapted from materials provided by Bruker Nano Surfaces and Metrology.

For more information on this source, please visit Bruker Nano Surfaces and Metrology.