With the growth of the Internet of Things, sustainable solutions for powering wireless sensors and devices are considered important. Thermoelectric generators, for example, which have the ability to convert waste heat into electricity, can offer a sustainable solution. Researchers around the world have been working on such solutions.

A research team, led by Masakazu Nakamura from Nara Institute of Science and Technology (NAIST), Japan has also been working on flexible wearable thermoelectric generators that produce electricity from body heat by sewing nanomaterials called carbon nanotubes (CNTs) into fabric.

Effective thermoelectric (TE) materials are characterized by high electrical conductivity enabling high electrical current and a large Seebeck coefficient generating voltage by temperature difference. CNTs meet most of these requirements. Their flexibility and high mechanical strength also make them promising for various TE applications. However, the high thermal conductivity of CNTs limits their TE performance.

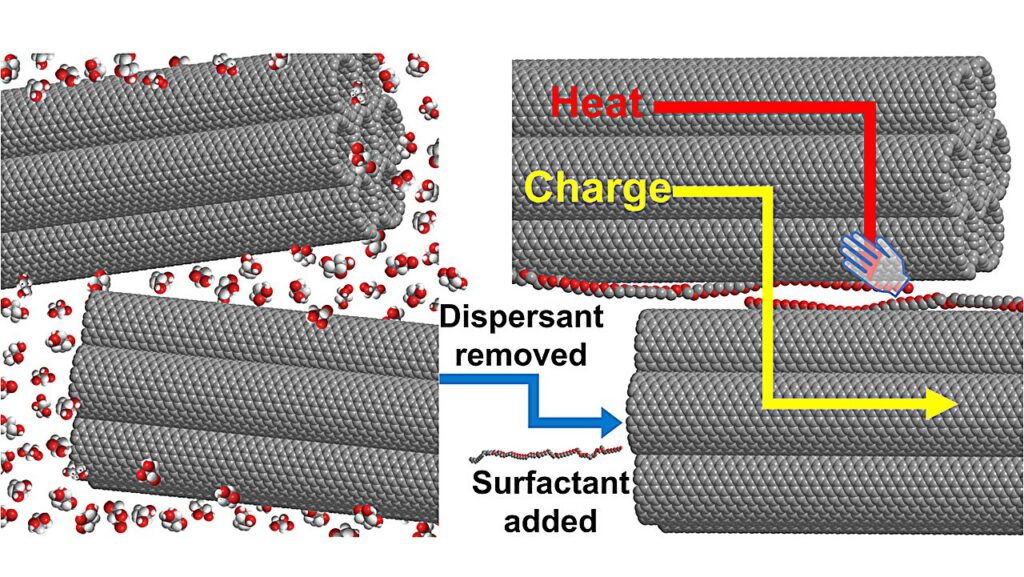

To lower their thermal conductivity, CNTs are dispersed in a solution where they can be combined with other materials. This dispersion is then spun into CNT yarns using a wet-spinning process. However, conventional dispersion methods often entangle nanometer-thick CNT filaments, which lowers their electrical conductivity and thermoelectric performance.

Now, however, in a study published in ACS Applied Nano Materials, Nakamura, along with a Ph.D. student Anh N. Nguyen and other members also from NAIST, introduce a new method for dispersing CNTs. By utilizing glycerol as a dispersant and polyoxyethylene(50) stearyl ether as a surfactant (a substance used to improve the spreading and wetting properties of a liquid), the researchers achieved a CNT yarn with aligned CNT bundles.

“We introduce a low-cost, fast, and environmentally friendly method for the development of flexible and fabric-type wearable thermoelectric devices,” says Nakamura.

Glycerol is highly viscous, making it an excellent medium for evenly dispersing CNTs, while the surfactant prevents the CNTs from agglomerating in the dispersion. The surfactants with oxyethylene groups also impede heat transfer by getting in between the CNT bundles.

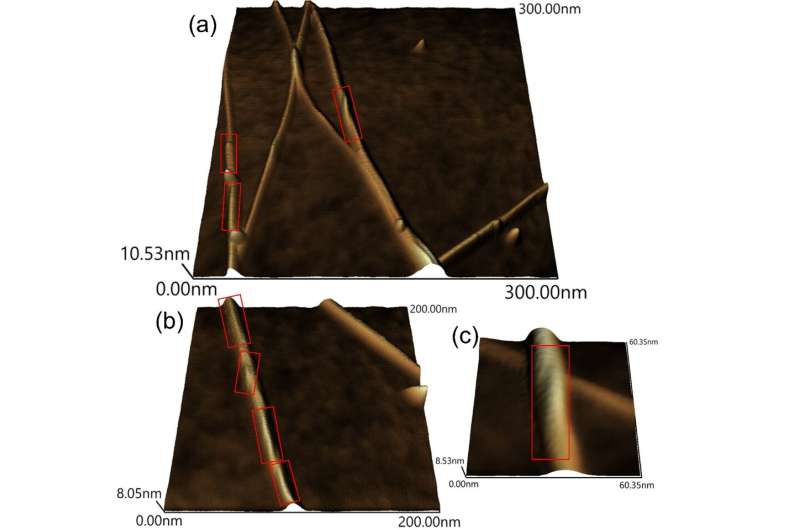

The concentration of surfactant is crucial, as it influences both the thermal and electrical conductivity of the CNT dispersion. After testing CNT properties at various surfactant concentrations (3%, 4%, and 5%), researchers found that a 3% surfactant concentration, when combined with a solution containing glycerol and CNTs, gave the best results. The process, which only took three hours to complete and used ecofriendly chemicals, produced CNT yarn with highly aligned eight nm diameter CNT bundles with surfactant between them.

Aligning the CNTs typically increases both the electrical and thermal conductivity. However, by sandwiching surfactant molecules between CNT bundles, researchers were able to suppress heat transport. The CNT yarns had a power factor of 242 μW m−1 K−2 (reflecting performance) three times higher than that of CNT yarns previously obtained from methods that use ionic liquids as dispersants.

“The key to high performance is to unravel the entanglement of the raw CNT material and increase the degree of CNT orientation when spun from the dispersion,” explains Nakamura.

Thus, the proposed novel approach holds promise for enhancing the thermoelectric performance of CNT materials from yarns to films and bulk structures.