The sun’s fusion reactions drive its temperatures to thousands of degrees, and today scientists are seeking to recreate these star-powering processes in the lab as a means of an alternative clean energy.

One avenue is inertial fusion energy experiments, but for those to work the fusion fuel must be held in precisely the right configuration, with one promising approach being to use a porous foam. The trouble is, no one is quite sure how well these nanofoams work because existing techniques either destroy them or lack the resolution to study them in detail.

Now, researchers report they’ve developed an X-ray imaging technique that leverages the unique properties of Linac Coherent Light Source (LCLS) at the Department of Energy’s SLAC National Accelerator Laboratory to resolve the 3D nanostructure of a copper foam with a level of precision that is relevant to fusion experiments.

“This type of 3D volume technique at a free-electron laser is a first-of-its-kind measurement,” said Adra Carr, research scientist at Los Alamos National Laboratory and lead author of the work published in Nano Letters on August 1.

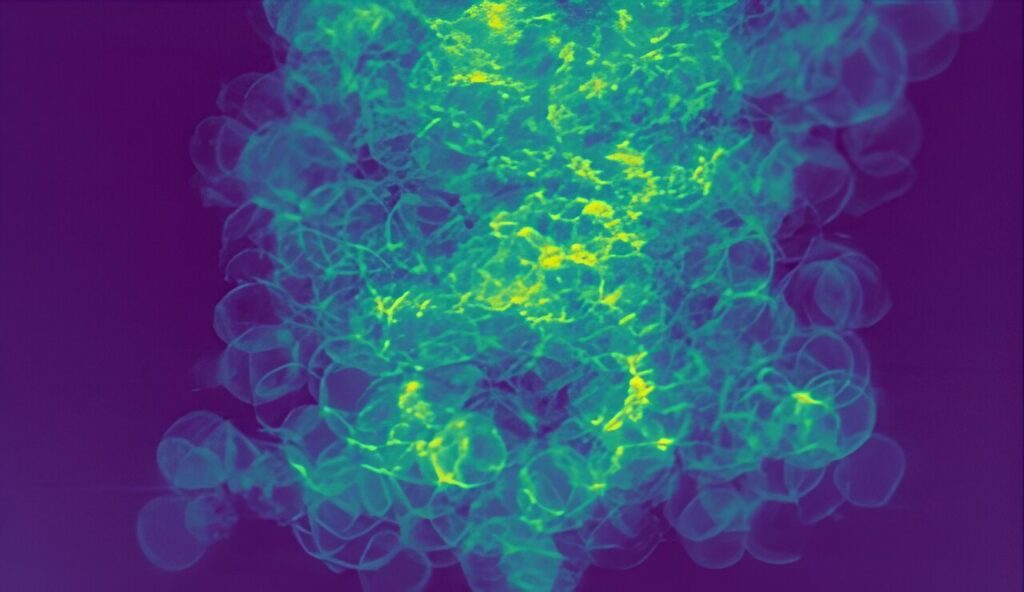

The technique is based on ptychographic imaging, which generates images by processing the patterns of photons scattered off a sample. The researchers scattered LCLS’s X-ray free-electron laser off copper foam samples, then used computer algorithms to “reconstruct” the original sample. These algorithms input the collected photon scattering patterns, ultimately reconstructing the copper foam with nanoscale resolution. Rotating the samples allowed them to render their structure in 3D.

“This new technique leverages the coherence and the brilliance of the X-ray free electron laser,” said Arianna Gleason, senior staff scientist at SLAC and a corresponding author on the new study. “We were able to interrogate the foam in a way that few other methods could achieve.”

The generated images showed that the copper foam is not as uniform as expected. Many of the thin shells of foam were distorted, merged or open—variations that could affect their performance in inertial confinement fusion experiments. That kind of information could be used to optimize foam fabrication methods and tailor these materials for fusion experiments.

This collaborative work relied on material expertise from Lawrence Livermore National Laboratory, where researchers conduct inertial confinement fusion experiments at the National Ignition Facility, coherent imaging expertise from Los Alamos and Brigham Young University and experimental design efforts with accelerator science expertise from SLAC.

“I think this work is a really wonderful example of how these types of experiments are only possible with diverse expertise across multiple fields and at unique places like SLAC,” Carr said.

The researchers hope their work will act as a springboard for future imaging experiments. They plan to apply this technique to other fusion-related materials, and Gleason said it could also be extended to other multi-material, nanoscale structures, or even fragile samples. Information from additional sensors could be incorporated to study the 3D nanostructures of samples over time or map their distribution of different chemical species.