In recent years, researchers have synthesized various new materials that could be used to develop more advanced robotic systems, devices and human-machine interfaces. These materials include graphene aerogels, ultralight, porous and graphene-based materials comprised of a single layer of carbon atoms arranged in a 2D honeycomb lattice.

While graphene aerogels have numerous advantageous properties, including a minimum weight, high porosity and good electrical conductivity, engineers who tried to use them to develop pressure sensors have encountered some difficulties. Specifically, many of these materials have an intrinsically stiff microstructure, which poses limits on their strain sensing capabilities.

Researchers at Xi’an Jiaotong University, Northumbria University (UK), UCLA, University of Alberta and other institutes recently introduced a new fabrication strategy for synthesizing aerogel metamaterials to overcome this limitation. This strategy, outlined in a paper in Nanoletters, fabricates a durable graphene oxide-based aerogel metamaterial that exhibits a remarkable sensitivity to human touch and motion.

“The research was purely driven by curiosity from my student, occasionally picking up on an abnormal structure change in the cross-section of a particular plane,” Dr. Ben Xu, co-author of the paper, told Phys.org. “This anisotropic phase change attracted interest. Soon we realized that the associated function change could enable a beautiful pressure sensing function directionally.”

The team’s strategy for fabricating graphene oxide-based metamaterials spans across two key steps. These include the use of a dehydration technique known as freeze drying and a heat treatment process known as annealing.

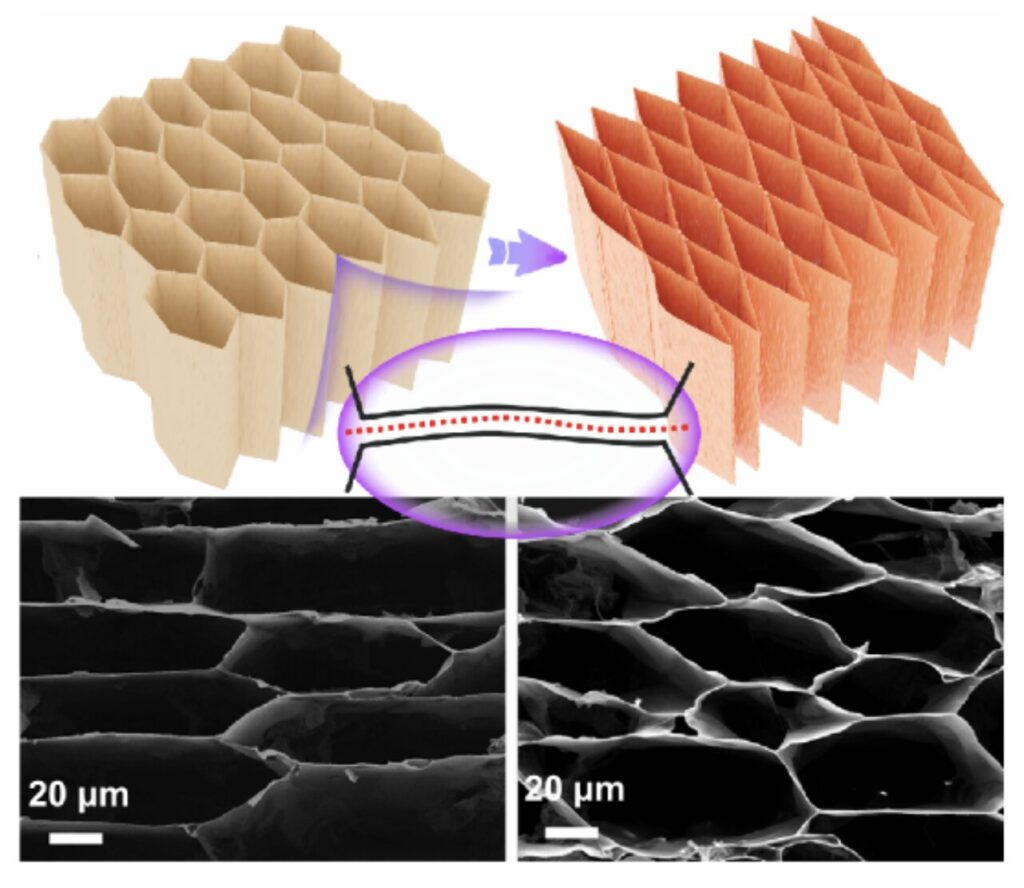

“The pre-solution also contains a specific chemical that acts as graphene ‘glue’ to construct the honeycomb type cross section,” explained Dr. Xu. “The structure configuration of the cross section on the dedicated plane is realized by thermal annealing, which can be tuned by micro-/nano-mechanics. Using this simple strategy, the buckled cross section was achieved on the first trial.”

Using their proposed fabrication strategy, Dr. Xu and his colleagues synthesized an anisotropic cross-linked chitosan and reduced graphene oxide (CCS-rGO) aerogel metamaterial. This material was found to exhibit a remarkable directional hyperelasticity, extraordinary durability, great mechanical and electrical performance, a long sensing range, and a very high sensitivity to stimuli of 121.45 kPa-1.

“We are now conducting multidisciplinary research with diverse interests in functional materials and energy technology, sustainable engineering, health care materials, materials chemistry, responsive materials/surface, and micro-engineering,” said Dr. Xu.

Dr. Xu’s team at Northumbria University is now conducting further studies aimed at developing promising metamaterials for various technological applications. In the future, their proposed fabrication strategy could contribute to the synthesis of additional graphene oxide-based aerogel metamaterials, which could advance human-machine interfaces for advanced health care and prosthetic devices.

Another development track for such sensors is in wind energy.

“We have recently focused a lot on the functional materials and engineering technology for the offshore wind energy sector,” added Dr. Xu. “We are also looking forward to applying our materials/sensor research in the newly awarded EU COST Action CA23155, to advance the novel ocean tribology. This project focuses on offshore wind energy, which contributes to the global target of net zero and sustainability.”