Hydrogen gas is a clean, renewable alternative to fossil fuels, but current industrial production methods used to produce hydrogen release carbon into the atmosphere and pollute the environment.

A new catalyst, carbon compound nickel-iron-molybdenum-phosphide anchored on nickel foam (NiFeMo-P-C), has significantly decreased the amount of electricity required to generate both hydrogen and oxygen from water, providing a clean and efficient means to produce hydrogen gas.

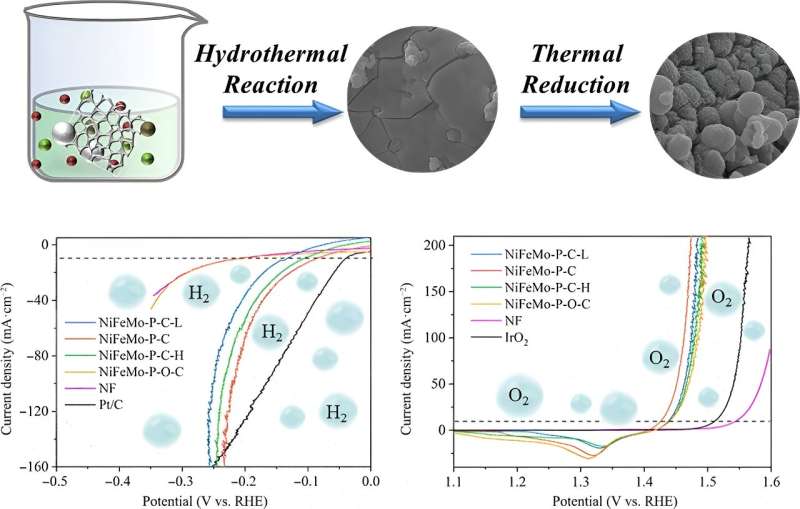

A team of leading chemical engineers have synthesized a cost-efficient and easily manufactured catalyst designed to lower the amount of energy required for the electrolysis of water, which splits water molecules into hydrogen and oxygen using electricity.

Hydrogen and oxygen gas are split from water through the hydrogen evolution reaction (HER) and oxygen evolution reaction (OER), respectively. The transition metal alloy, or mixture containing at least one metal, nickel-iron-molybdenum (NiFeMo) was used as a catalyst for water electrolysis due to the incomplete filling of electron orbitals in transition metal atoms nickel and iron, making it an ideal electron donor and acceptor in chemical reactions. Phosphide was added to the catalyst to improve corrosion resistance in an alkaline, or basic pH, electrolyte solution.

The team published the results of their study in Nano Research Energy on July 7.

“Hydrogen is recognized as the most ideal alternative to fossil fuels due to its high… energy density, high heat conversion efficiency and zero carbon emission. However, commonly applied hydrogen production methods in industry, including steam reforming of natural gas and methanol and gasification of coal, consume fossil fuels and cause serious pollution to the environment,” said Jingjing Tang, supervisor of the study and associate professor at Central South University in Changsha, China.

“Water electrolysis takes water as raw material to produce high-purity hydrogen by converting electricity into chemical energy, which is a clean and promising hydrogen production technology,” said Tang.

Catalysts used to lower the energy required for both the HER and OER existed previously, but utilized platinum and iridium oxide, valuable elements that are both expensive and in short supply. Creating an affordable catalyst that lowers the activation energy of both reactions reduces overall manufacturing costs and improves the commercial viability of clean hydrogen gas production.

One challenge in designing a bifunctional catalyst was the special requirements of the OER. “Because OER is a four-electron transfer reaction with sluggish kinetics, [it] generally performs better in alkaline solution. It was critical to research non-noble, metal-based electrocatalysts with excellent bifunctional performance in [an] alkaline electrolyte,” said Tang. The team created the alloy and metal phosphide to maintain catalyst integrity in these alkaline conditions.

To test the composition and valence state of the generated NiFeMo-P-C catalyst, the team subjected the compound to X-ray photoelectron spectroscopy (XPS) measurement to confirm the presence of Ni, Fe, Mo, P, C and O. The high-resolution spectrum of nickel also identified 2p3/2 and 2p1/2 spin orbits, which refers to the state of electrons in the nickel atoms of the catalyst.

Overall, the newly developed NiFeMo-P-C electrocatalyst requires very low overpotentials, or energy required to split water, for HER (87 mV to achieve a current density of 10 mA·cm–2) and OER (196 mV to achieve a current density of 10 mA·cm–2). The cell voltage, or difference in voltage between two electrodes, required for water electrolysis using the catalyst is also only 1.50 V at 10 mA·cm–2.

The team is optimistic that their discovery will make clean hydrogen production a reality. “Unlike most bifunctional catalysts, NiFeMo-P-C can achieve excellent catalytic performance without complicated preparation steps and elaborate nanostructures. Besides, the superior durability without any [voltage] attenuation within 50 hours… makes NiFeMo-P-C an ideal [non-precious metal catalyst] candidate… for large-scale hydrogen production,” said Tang.

Other contributors include Xiangyang Zhou, Tingting Yang, Ting Li, Youju Zi, Sijing Zhang, Lei Yang, Yingkang Liu and Juan Yang from the School of Metallurgy and Environment at Central South University in Changsha, China.

Provided by

Tsinghua University Press