A new “nanostring” has the highest quality factor ever recorded for a room-temperature mechanical resonator, vibrating for unprecedented periods of time while dissipating hardly any energy. The device, which measures centimetres in length but just nanometres in diameter, could be used to detect ultra-small forces such as gravity.

Nanomechanical resonators are tiny vibrating beams that oscillate at very high resonant frequencies – often in the megahertz or gigahertz range. They are employed in wireless communication for signal processing, and in basic research for detecting and determining the mass of tiny objects such as single DNA molecules or viruses. The latter application works on the principle that whenever a small particle is absorbed onto the beam, the frequency at which the beam vibrates will change in a way that can be monitored and used to calculate the particle’s mass.

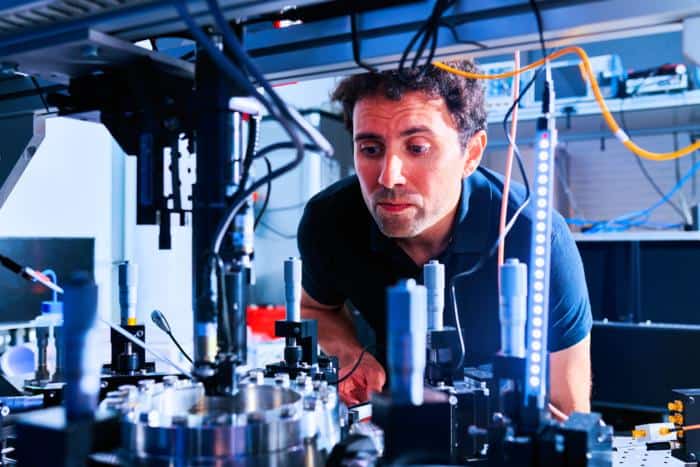

Long, thin resonators are more sensitive than resonators with a lower aspect ratio, but they are hard to fabricate. In the latest work, a team led by Richard Norte of TU Delft in the Netherlands, together with Miguel Bessa of Brown University, US, overcame this challenge by using machine learning to design the resonator and advanced nanofabrication processes to make it. The resulting “nanostrings” are three centimetres in length but just 70 nm thick – “equivalent to suspending a freely-standing 1 mm thick guitar string made from a ceramic material over half a kilometre with almost no sag,” Norte says. “Such a structure would be impossible to produce at our everyday macroscales.”

The new vibrating sensor can register some of the smallest forces in science, at levels of sensitivity that have only previously been possible at temperatures near absolute zero, Norte adds. This sensitivity stems from the device’s extremely high quality factor (Qm), which at kilohertz frequencies can be up to 10 billion – meaning that the nanostring can vibrate 100 000 times per second while losing very little energy.

Unprecedented levels of sensitivity

To make the sensor, the researchers chose a high-stress material, silicon nitride (Si3N4), that is commonly used in resonators. An algorithm known as multi-fidelity Bayesian optimization helped them find a good design quickly and efficiently, having first specified that the algorithm should consider devices made from a slab of Si3N4 tens of nanometres thick, freely suspended over a length of several centimetres and placed on a microchip of silicon.

The algorithm suggested a resonator with a length of 3 cm and aspect ratios greater than 4.3 x 105. To make a device according to this exacting specification, the researchers deposited the Si3N4 on 2-mm silicon wafers manufactured with low-pressure chemical vapour deposition (LPCVD). They then used electron beam lithography or photolithography to pattern a “scaffolding” layer that they subsequently removed using chemical etching. This last step produces a string that has not been subjected to any additional forces during manufacturing, which could otherwise lead it to collapse or fracture, Norte says.

Record-breaking quality factor

To characterize the device, the team set it vibrating with piezoelectric stages and used an optical interferometer to measure the time it took for the vibrations to stop. These “ringdown” measurements provide information about how fast the resonator’s amplitude decays, and thus the rate at which it dissipates energy – values that are then used to calculate Qm. For a 3-cm-long Si3N4 string, they achieved a Qm exceeding 6.5 × 109 at room temperature, which is the highest value ever recorded for a mechanically clamped resonator of this kind.

Writing in Nature Communications, the researchers report that almost no energy is lost to the exterior of the microchip-based resonator. This is because vibrations get trapped in the middle of the string, they say. “It also means that noise from our hot, everyday environment cannot enter the centre of the string either, so shielding it and allowing it to sense even the smallest forces,” Norte explains. “It is somewhat like a swing that, once pushed, keeps swinging for almost 100 years because it loses almost no energy through the ropes.”

The researchers would now like to make more complex structures such as membranes or drumheads. They are also studying ways of using high-aspect-ratio nanotechnology to make ultra-thin lenses and mirrors. “These have applications in imaging, sensing and even ambitious space missions like Breakthrough Starshot that aim to send reflective sails into interstellar space,” says Norte. “We think this is really just the beginning of new playground that mixes nanotechnology and machine learning.”