A research team has developed technology that could dramatically increase the lifespan and energy density of electric vehicle (EV) batteries.

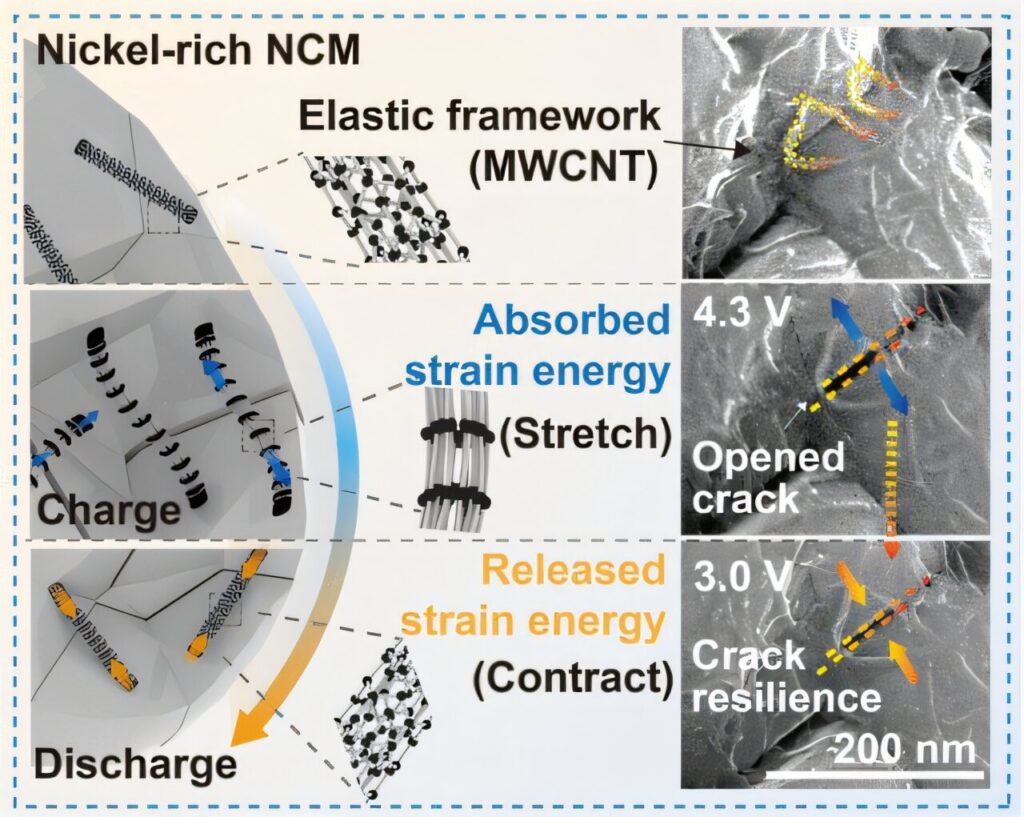

An EV battery must maintain its performance while repeatedly being charged and discharged. However, the current technology has one big issue: the charging and discharging process causes the battery’s positive active materials to expand and contract repeatedly, causing microscopic cracks within. As time goes, the battery performance drastically decreases. To prevent this, researchers are increasing the strength of the cathode active materials or by adding reinforcement dopant, but these can not become a fundamental solution.

The key to this research, recently published in ACS Nano, is the nano-spring coating technology that can design elastic structures. The research team implemented a multi-walled carbon nanotube (MWCNT) on the surface of battery electrode materials. This absorbed strain energy generated from the charging and discharging process, preventing cracks, and minimizing thickness changes in electrodes to improve stability. The team successfully and effectively suppressed cracks within the battery and simultaneously improved its lifespan and performance.

This technology allows researchers to minimize resistance caused by volume changes of the material with only a small amount (0.5wt%, weight percentage) of conductive material. It can realize a high energy density of 570 Wh/kg or above. Also, it shows excellent lifespan by maintaining 78% of the initial battery capacity after 1,000 charge and discharge cycles or above.

In particular, this technology can be easily combined with the existing battery manufacturing processes, allowing easy mass production and commercialization. This development is expected to overcome current limitations in battery technology, paving the way for more efficient and durable EV batteries. This can contribute to the development of electric vehicles that are superior to the existing ones.

The team was led by Professor Kyu-Young Park from the Institute of Ferrous & Eco Materials Technology, Department of Materials Science & Engineering, POSTECH conducted joint research with Samsung SDI, Northwestern University, and Chung-Ang University.

Professor Park of POSTECH said, “With a different approach from existing ones, this research effectively controlled changes that could occur to a battery during the charging and discharging process. This technology can be widely used not only in the secondary battery industry but also in various industries where material durability is important.”