Have you ever imaged high-resolution 3D structures at the micro/nanoscale that react dynamically to their surroundings? The 4D printing technology is changing the game by using smart materials that exhibit remarkable shape deformation in response to external stimuli, showing the enormous potential for use in biomedicine, flexible electronics, soft robotics, and aerospace.

But there’s a huge challenge: for 4D printing to step into the micro world, we need a higher resolution 3D printing technology capable of achieving sub-micrometer or even smaller-scale features.

In a publication in the International Journal of Extreme Manufacturing, Prof. Qi Ge’s team from Southern University of Science and Technology introduces a game-changer— Two-photon polymerization-based (TTP-based) 4D printing technology, which can fabricate high-resolution, ranging from 90 nm to 500 nm, and transformable 3D structures at the micro/nanoscale.

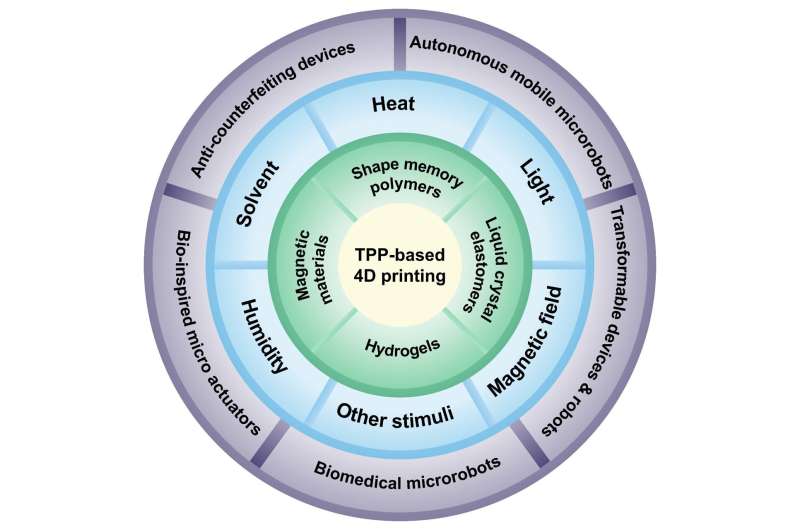

This paper aims to summarize the current advancements of the TPP-based 4D printing technology and its associated applications. It commences by elucidating the technological advancements of TPP-based 4D printing, delineating its foundational working principle and recent progress.

Additionally, the review encapsulates the strides achieved in smart materials harnessed for TPP-based 4D printing. Last, the paper accentuates the quintessential applications of TPP-based 4D printing, including the realms of biomedical microrobots, bioinspired microactuators, autonomous mobile microrobots, transformable microrobots, and anti-counterfeiting devices.

“TPP technology empowers the fabrication of multifunctional micro/nanostructures by selecting appropriate photoresist materials tailored to the desired functions of the target application,” said Bingcong Jian, the first author of the paper.

“These specialized photoresists enable the creation of micro/nanostructures exhibiting dynamic properties such as stimulus responsiveness, biomimetic self-actuation, color-changing, and shape-morphing capabilities, which are beyond the reach of commercial photoresists. The 4D printing materials suitable for TPP are introduced according to four categories: magnetic materials, shape memory polymers, hydrogels, and liquid crystal elastomers.”

4D printing is a programmed transformation of the 3D printed structure in shape, property, and functionality. It can realize shape-morphing, multi-functionality, self-assembly, and self-repair. It is printer-independent, time-dependent, and programmable. The emergence of TPP-based 4D printing technology holds the promise of revolutionizing various fields, including robotics, biomedicine, and nanotechnology, in the near future.

The applications are classified based on structural evolutions and changes, such as shape morphing, color alteration, state switching, and locomotion. Consequently, the potential applications of TPP-based 4D printed structures can be grouped into five categories: biomedical micromachines, bioinspired microactuators, autonomous mobile microrobots, transformable devices and robots, and anti-counterfeiting microdevices.

“As we venture deeper into the realm of TPP-based 4D printing, we’re met with both excitement and intriguing challenges,” notes Qi Ge. “Our path forward involves addressing these challenges with an eye toward innovation and adaptation.

“A paramount concern is the need to enhance our manufacturing capability. To make TPP-based 4D printing an integral part of diverse industries, we must develop equipment capable of cross-scaling and handling multiple materials at the micro/nanoscale. This entails a journey toward greater printing speed, scalability, and precision. Equally critical is our quest to optimize material performance. The photoresists we employ are the lifeblood of our creations.

“To achieve structural transformations and functional excellence, we need to innovate and refine photoresists with superior chemical, thermal, and mechanical attributes. These materials must be robust, flexible, and durable. However, the heart of our future endeavors lies in our design methodology. We’re exploring ways to synthesize process, material, structure, and function into a harmonious design framework.

“This approach leverages topological optimization and machine learning to refine the printing process, material choices, and structural designs simultaneously. The result is the ability to craft micro/nanostructures with tailored functionalities.

“Our aspiration is clear. Through advanced design techniques, we aim to unlock new horizons in TPP-based 4D printing. Overcoming these challenges isn’t just about technological advancement; it’s about reshaping industries and pioneering innovative applications. We’re excited to embark upon this journey as we chart the future of TPP-based 4D printing.”

Provided by

International Journal of Extreme Manufacturing