Fingerprint detection is one of the most important techniques in forensic investigation. When fingerprints are dusted with a carbon-based powder, the material will adhere to the moisture and grease left behind by the unique patterns of ridges and valleys on the perpetrator’s fingertip. The resulting pattern can then be analyzed under a microscope, and compared with suspects’ fingerprints.

Researchers led by Bienvenu Gael Fouda-Mbanga at Nelson Mandela University, Gzeberha, South Africa, have discovered a new type of powder for dusting fingerprints. It allowed them to image their nanoscale details more clearly while deepening the contrast between ridges and valleys. This work is now published in Hybrid Advances.

Made from manganese-doped iron oxide nanoparticles and coated in an activated wool char, this new material could help forensic investigators solve crimes more easily.

Recently, metal-oxide nanoparticles have become increasingly popular in fingerprint detection. Not only are they easy to produce, but they also have a high surface area and chemical reactivity, allowing them to interact strongly with the chemical compounds contained in fingerprint residues.

When coated in carbon, these nanoparticles create a deeper contrast in fingerprint images, making them far easier to analyze.

In their study, Fouda-Mbanga’s team fabricated their iron oxide nanoparticles using a low-cost, environmentally friendly “hydrothermal” method. They then coated the particles with activated charred wool. This widely available agricultural waste product is chemically inert, making it safer to use than conventional carbon-based powders, while also enhancing the stability of the more reactive nanoparticles.

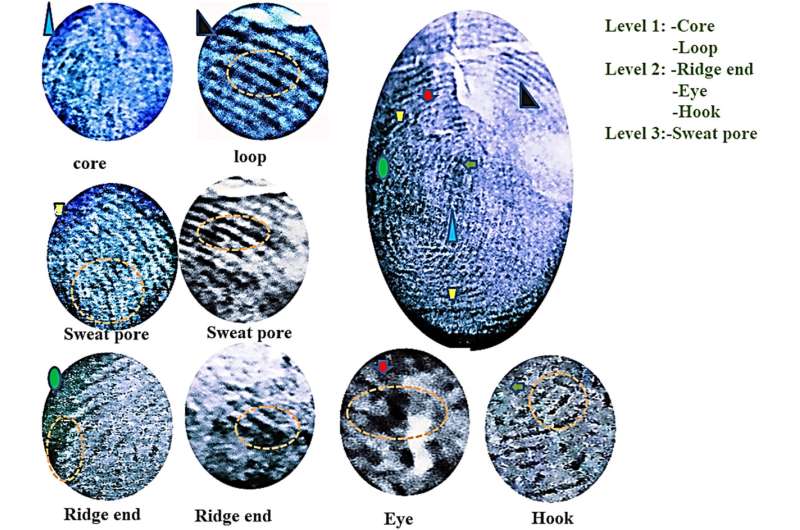

To examine their powder’s performance, the researchers used it to dust fingerprint residues on a non-porous aluminum surface. They then employed several different types of electron microscopy and light spectroscopy to image them.

The images they produced were incredibly promising, revealing details down to a nanoscale resolution while showing a starker contrast than many types of powder tested in previous studies. Following this success, Fouda-Mbanga’s team now hope that their approach to nanoparticle fabrication could soon be applied more widely in forensic investigation.