Earning public admiration through a well-maintained physical appearance is a fundamental aspect of human psychology. The demands of personal care significantly drive the creation of innovative cosmetic products.

Image Credit: Inovenso

The utilization of nanofibers and nanostructures in cosmetics is commonly known as “nanocosmetics.” These products aim to deliver enhanced performance, better skin penetration, and improved appearance.

Nanofibers exhibit significant potential in cosmetics due to their unique properties, such as small pore size and high porosity. These characteristics enable them to absorb large quantities of liquids, ensuring high retention levels of agents, vitamins, and nutrients for effective delivery to the skin.

Their oxygen and water permeability features also make them suitable for breathable cosmetic applications like cleansers and moisturizers.

The large surface area of nanofibers additionally increases the contact surface between the mesh and the skin, facilitating the efficient delivery of active agents to deeper skin layers. Moreover, their substantial mechanical strength makes them ideal templates for artificial skin applications.

Electrospinning is a simple, cost-effective method for producing nanofiber mats with controllable pore sizes and fiber diameters. This technique could be employed in creating advanced cosmetic products, including nanofiber facial masks for skin therapy, cleansing, and healing.

Electrospun nanofibers serve as effective carriers for encapsulating and delivering active cosmetic ingredients. The large surface area and porosity of electrospun nanofibers ensure the controlled release of ingredients, offering prolonged and more successful results – especially in anti-aging and skincare formulations.

Although not directly related to cosmetics, electrospinning can be utilized to generate scaffolds for tissue engineering – which are useful in reconstructive or cosmetic surgery to enhance or restore physical appearance.

Electrospun nanofibers also contribute to the development of lightweight and transparent sunscreen formulations, offering improved sun protection without the typical heaviness and greasiness associated with traditional sunscreens.

Electrospinning can also be used to produce nanofiber-based cosmetic face masks and patches. These products have exceptional features compared to their commercial counterparts. Some of these features are discussed below:

- The items offered are entirely natural, devoid of any chemicals such as preservatives and emulsifiers.

- They serve as excellent substitutes for heavy creams, gels, and masks, providing a superior fit, enhanced breathability, and intensive skin rejuvenation. This is achieved through deeper penetration and improved delivery of skin-friendly ingredients.

- The nanofibers’ minimal size ensures instant and noticeable revitalization and a radiant glow on the skin.

- Application is simple, ensuring 100 % effective use of skin agents, vitamins, and nutrients. The structure is thinner and more comfortable compared to traditional sheet masks and patches.

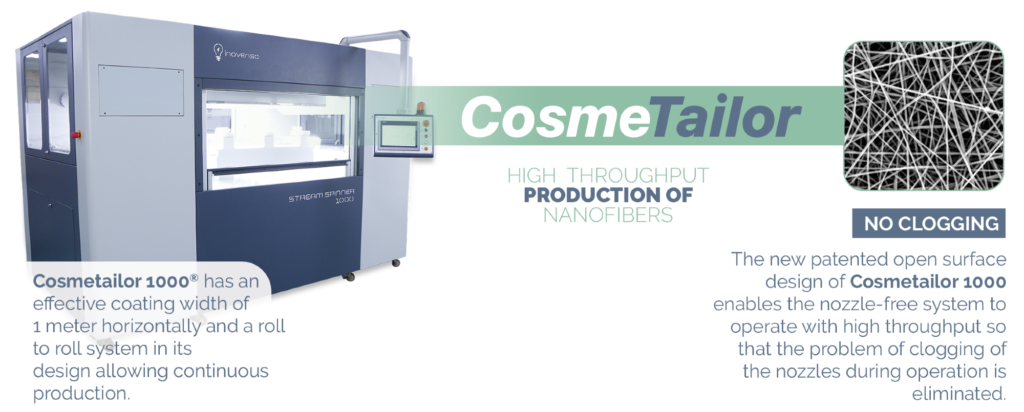

The “Inovenso’s Cosmetailor 1000” facilitates the production of nanofiber-based cosmetic facemasks with varied compositions, including hyaluronic acid, collagen, aloe vera, vitamins, nutrients, and more for enhanced skin quality.

The “Cosmetailor 1000” has an efficient coating width of 1 meter horizontally. Its roll-to-roll system enables continuous production.

The new patented open surface design of the “Cosmetailor 1000” allows the nozzle-free system to function with high throughput, effectively eliminating issues related to nozzle clogging during operation.

Production capacities for nanofiber-based cosmetic masks and patches developed using HA are detailed below.

The daily production rate for 2.5 GSM (grams per square meter) nanofiber density using Cosmetailor 1000 with:

- 8 hours and 2 shifts will produce 2750 cosmetic masks per day.

- 6 hours and 3 shifts will produce 3093 cosmetic masks per day.

- 8 hours and 2 shifts will produce 17280 pairs of cheek (under the eye) patches.

- 6 hours and 3 shifts will produce 19440 pairs of cheek (under the eye) patches.

- 8 hours and 2 shifts will produce 14811 forehead & neck patches.

- 6 hours and 3 shifts will produce 2777 forehead & neck patches.

The exceptional diffusion rate of electrospinning in various life sciences and technology applications is anticipated to accelerate further, offering solutions to daily life problems, including cosmetic concerns. These developments naturally translate into the market as the creation of new products.

This information has been sourced, reviewed, and adapted from materials provided by Inovenso.

For more information on this source, please visit Inovenso.