From cell phones to solar panels to quantum computers, thin films are essential to current and emerging technologies. But making functional thin films requires control. During hours-long processes, thin films form atom by atom. Small changes in data readouts can tell researchers when something is going wrong. Detecting defects as soon as possible may help scientists fix films while they’re growing, saving time and money.

Researchers at Pacific Northwest National Laboratory (PNNL) are using machine learning (ML) to identify subtle changes in growing films that are imperceptible to humans, detailed in a paper published in the Journal of Vacuum Science & Technology A. Their ML program can pinpoint emerging differences in film growth data faster than human experts, an important initial step toward developing autonomous experimentation with instruments that can make data-based decisions without additional human input.

“What we’re doing is finding a way to make ML work for us,” said Tiffany Kaspar, a materials scientist at PNNL and the lead investigator of the project. “To make changes that can actually affect film growth, every second matters. Often, by the time we notice something’s going wrong, it’s too late to fix the film. As we train our ML program with more data, it should get even better at finding changes.”

The work is a collaboration between materials and data scientists. The initiative brings together scientists from different fields to co-develop the hardware, software, and instrumental knowledge required to achieve autonomous materials science.

RHAAPsody in films

The project started with growing films. The team picked titanium dioxide as their model system because it has the right blend of simplicity and complexity. The material can form several different potential structures, depending on the growth conditions.

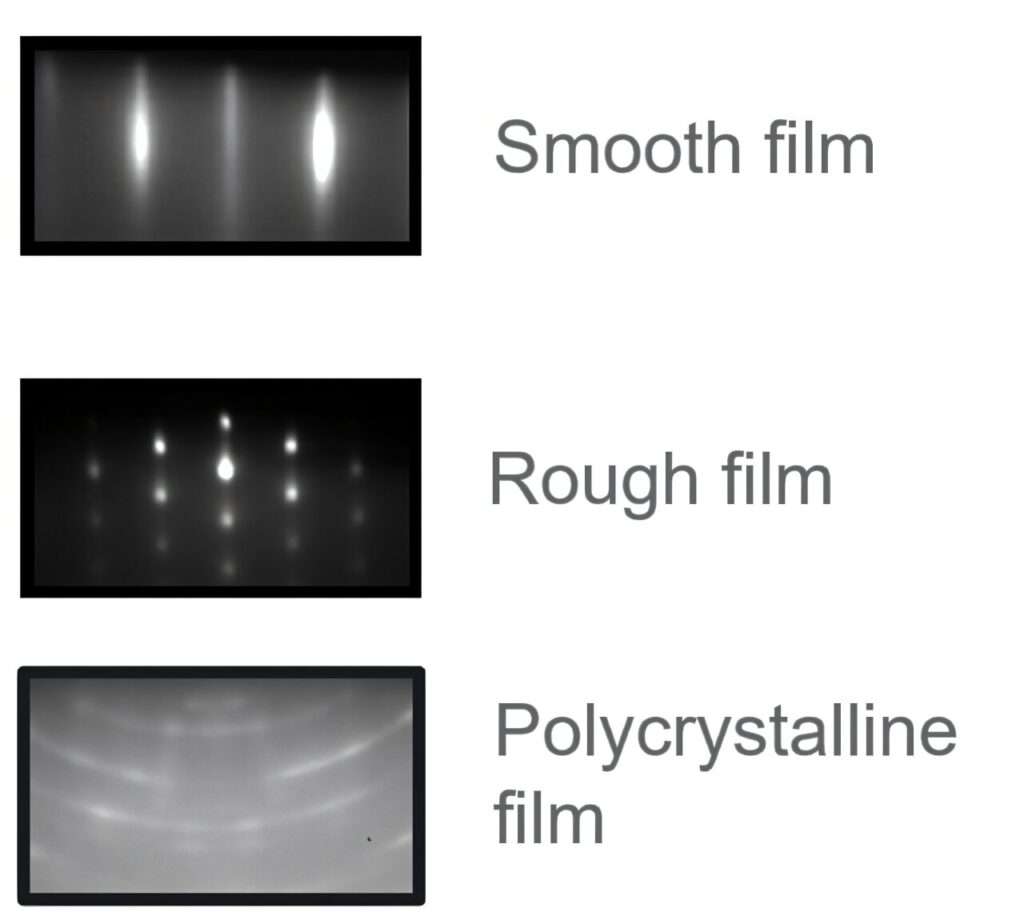

The growing films were deposited atom by atom and were far too thin to be seen with the naked eye. Instead, the team collected images of electron beam diffraction, captured once every second, to visualize the structure of the growing film. The captured images show streaks, spots, and other patterns that correspond to characteristics of the film’s crystalline structure and surface topography.

Traditionally, a human would watch these patterns to track the film’s progress toward an ideal smooth surface, a problematic rough surface, or a completely unintended structure. Now, using ML methods, a computer can automatically perform these tasks.

“Working with the film data proved quite challenging,” said Sarah Akers, who led the ML development work. “We were surprised to find that there was so little data easily available in the community to train our machine learning models. We’re planning to make our data accessible to others to hopefully accelerate more innovation.”

The ML process, termed RHAAPsody by the scientists, starts by converting the instrument measurements into a data format that’s easier for the ML algorithm to use for complex, but rapid, analysis. The algorithm then looks for points where things begin to change, comparing the data from one second to the next. These “change points” are then flagged by the program. The team worked intensely to determine how to clearly represent the data to show the changes.

Beyond flagging the changes, additional graphic-based analyses can help researchers visualize film evolution, leading to a deeper understanding of the film growth process itself.

Autonomous experimentation in the laboratory of the future

To test RHAAPsody, the team had a film growth researcher watch the same titanium dioxide deposition data and identify when they saw a shift in the images. Not only did RHAAPsody find the change points just like the experts, but it flagged them about a minute faster.

“This improvement in detection time is huge for developing real-time feedback in our system,” said Kaspar.

The end goal of the project is to create a fully autonomous film growth system. In the next stage, the instrument will seek to identify when the structure of a film is starting to go in the wrong direction and adapt the growth conditions to counteract the problem. This constant monitoring and active defect mitigation will build from connections among the instruments, computer hardware, and software developed by the team. The connected system will incorporate new predictive control algorithms, a key component of eventual autonomous experiments.

RHAAPsody represents a key step toward this autonomous instrument. “Before you can make decisions, you have to know when the branch points are,” said Akers.

The team is developing the next part of the process—using the data and ML process to change growth conditions.

“The possibilities are endless,” said Kaspar. “Imagine pairing an autonomous instrument with artificial intelligence-driven materials prediction that produces some sort of wild material we don’t know how to grow right now. The process isn’t perfect, but the opportunities are thrilling.”