As the demand for thinner, lighter, and more flexible electronic devices grows, the need for advanced manufacturing processes has become critical. Polyimide (PI) films are widely used in these applications due to their excellent thermal stability and mechanical flexibility. They are crucial for emerging technologies like rollable displays, wearable sensors, and implantable photonic devices.

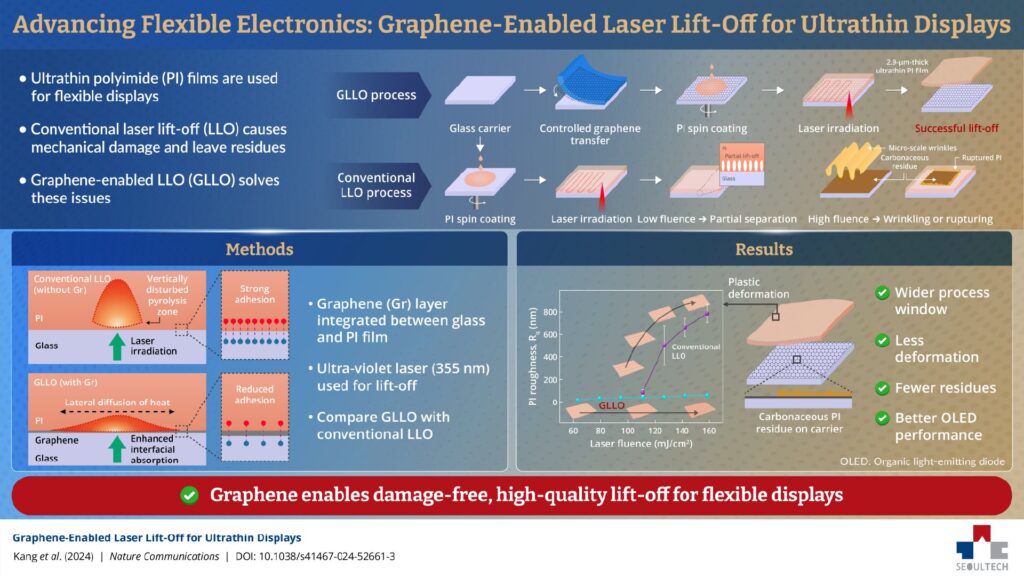

However, when the thickness of these films is reduced below 5 μm, traditional laser lift-off (LLO) techniques often fail. Mechanical deformation, wrinkling, and leftover residues frequently compromise the quality and functionality of ultrathin devices, making the process inefficient and costly.

In this view, researchers turned to graphene, a nanomaterial known for its exceptional thermal and mechanical properties. A research team from Seoul National University of Science and Technology, led by Professor Sumin Kang, has designed a novel technique to overcome the challenges with the LLO process.

Their innovative graphene-enabled enhanced laser lift-off (GLLO) method ensures ultrathin displays can be separated smoothly and without damage—making them perfect for wearable applications. Their study was published in the journal Nature Communications on September 27, 2024.

In this study, they have introduced a novel GLLO process that integrates a layer of chemical vapor deposition-grown graphene between the PI film and its glass carrier.

“Graphene’s unique properties, such as its ability to absorb ultra-violet (UV) light and distribute heat laterally, enable us to lift off thin substrates cleanly, without leaving wrinkles or residues,” says Prof. Kang.

Using the GLLO method, the researchers successfully separated 2.9 μm thick ultrathin PI substrates without any mechanical damage or carbon residue left behind. In contrast, traditional methods left the substrates wrinkled and the glass carriers unusable due to stubborn residues. This breakthrough has far-reaching implications for stretchable electronics and wearable devices.

The researchers further showcased the potential of the GLLO process by creating organic light-emitting diode (OLED) devices on ultrathin PI substrates. OLEDs processed with GLLO retained their electrical and mechanical performance, showing consistent current density-voltage-luminance properties before and after lift-off. These devices also withstood extreme deformations, such as folding and twisting, without functional degradation.

Additionally, carbonaceous residues on the glass carrier were reduced by 92.8%, enabling its reuse. These findings highlight GLLO as a promising method for manufacturing ultrathin and flexible electronics with improved efficiency and reduced costs.

“Our method brings us closer to a future where electronic devices are not just flexible, but seamlessly integrated into our clothing and even our skin, enhancing both comfort and functionality,” says Prof. Kang. Using this method, flexible devices that provide real-time monitoring, smartphones that roll up, or fitness trackers that flex and stretch with your movements can be designed easily.

Moving forward, the research team plans to optimize the process further, focusing on complete residue elimination and enhanced scalability. With its potential to revolutionize the electronics industry, the GLLO process marks a significant stride toward a future where ultrathin, flexible, and high-performance devices become viable options for daily use.

Provided by

Seoul National University of Science & Technology