With strong bactericidal properties, graphene has the potential to become a game changer in the fight against antibiotic-resistant bacteria. So far there have been no efficient ways to control these properties—and thus no way to make use of graphene’s potential in health care.

Now researchers at Chalmers University of Technology, in Sweden, have solved the problem by using the same technology found in an ordinary fridge magnet. The result of which, is an ultra-thin acupuncture-like surface that can act as a coating on catheters and implants—killing 99.99% of all bacteria on a surface.

Health care–associated infections are a widespread problem around the world, causing great suffering, high health care costs and a heightened risk of increased antibiotic resistance. Most infections occur in connection with the use of various medical technology products such as catheters, hip prostheses, knee prostheses and dental implants, where bacteria are able to enter the body via a foreign surface.

At Chalmers University of Technology, researchers have been exploring how graphene, an atomically thin two-dimensional graphite material, can contribute to the fight against antibiotic resistance and infections in health care.

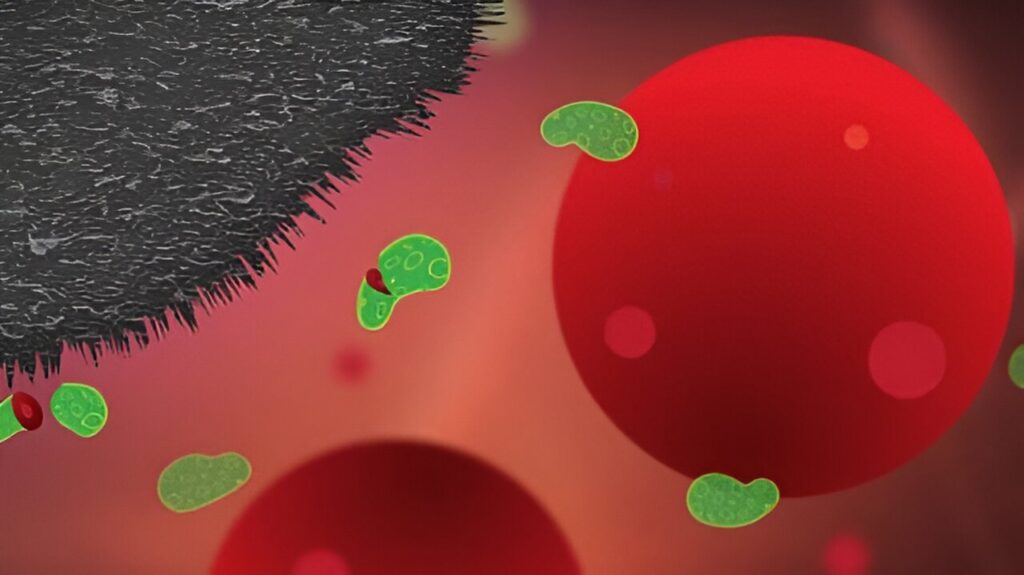

The research team has previously been able to show how vertically standing graphene flakes prevent bacteria from attaching to the substrate. Instead, the bacteria are cut to pieces on the razor-sharp flakes and die.

“We are developing a graphene-based, ultra-thin, antibacterial material that can be applied to any surface, including biomedical devices, surgical surfaces and implants to exclude bacteria.

“Since graphene prevents bacteria from physically attaching to a surface, it has the added advantage that you do not risk increasing antibiotic resistance, unlike with other chemical alternatives, such as antibiotics,” says Ivan Mijakovic, Professor of Systems Biology at Chalmers University of Technology and one of the authors of the recently published study.

Kills 99.99% of bacteria on a surface

However, the researchers have been facing a challenge. Although its bactericidal properties can be demonstrated in the laboratory, the researchers have not yet managed to control the orientation direction of the graphene flakes—and have subsequently not been able to apply the material on surfaces used on medical devices used in health care.

So far, the bactericidal properties of graphene have only been able to be controlled in one specific direction: the flow direction of the manufacturing process. But now the Chalmers researchers have had a promising breakthrough for a practical application in health care—and beyond.

“We have managed to find a way to control the effects of graphene practically in several different directions and with a very high level of uniformity of the orientation. This new orientation method makes it possible to integrate graphene nanoplates into medical plastic surfaces and get an antibacterial surface that kills 99.99% of the bacteria that try to attach.

“This paves the way for significantly greater flexibility when you want to manufacture bacteria-killing medical devices using graphene,” says Roland Kádár, Professor of Rheology at Chalmers University of technology.

Unpreceded efficiency by controlling magnetic fields

By arranging earth magnets in a circular pattern making the magnetic field inside the array arrange in a straight direction, the researchers were able to induce a uniform orientation of the graphene and reach a very high bactericidal effect on surfaces of any shape.

The method, published in Advanced Functional Materials, is called “Halbach array” and means that the magnetic field inside the magnet array is strengthened and uniform while it is weakened on the other side, enabling a strong unidirectional orientation of graphene. The technology is similar to what you would find in a refrigerator magnet.

“This is the first time the Halbach array method has been used to orient graphene in a polymer nanocomposite. Now that we have seen the results, of course we want these graphene plates to get introduced in the health care sector so that we can reduce the number of health care-related infections, reduce suffering for patients and counteract antibiotic resistance,” says Viney Ghai, researcher in Rheology and Processing of Soft Matter at Chalmers University of Technology.

The new orientation technology shows significant potential in other areas, for example in batteries, supercapacitors, sensors and durable water-resistant packaging materials.

“Given its broad impact across these areas, this method truly opens up new horizons in material alignment, providing a powerful tool for the successful design and customization of nanostructures that biomimic the intricate architectures found in natural systems,” says Kádár.