If there’s one thing we humans are good at, it’s producing heat: significant amounts, and in many cases most of the energy we generate and put into our systems we lose as heat, whether it be our appliances, our transportation, our factories, even our electrical grid.

“Waste heat is everywhere,” said UC Santa Barbara mechanical engineering professor Bolin Liao, who specializes in thermal science and renewable energy. “Our power plants, our car exhaust pipes—there are so many places where we create excess heat waste.”

For the moment, we’re fairly limited as to how we can make the most out of this dissipating heat. But Liao and UCSB colleagues, alongside collaborators from Ohio State University and University of Hong Kong, are making headway toward putting that heat to use, with a first-time comprehensive characterization of the thermoelectric properties of high-quality cadmium arsenide thin films.

“If we could harvest that waste heat then that would be fantastic,” he said. “That would really increase our energy efficiency and it’s also a really sustainable energy source.”

The team’s research is published in the journal Advanced Materials.

A better thermoelectric material

“To obtain high efficiency, we need the material to conduct electricity well, conduct heat poorly and generate a high voltage for a given temperature difference,” Liao said. Poor heat conduction minimizes heat dissipation while maintaining a temperature difference across the material, resulting in an electric current enhanced by the material’s high-performing electric conductivity. The voltage resulting from a temperature gradient is known as the Seebeck effect.

This combination of electrical and thermal transport properties is ideal, but according to Liao, “very hard to achieve in practice.”

Enter cadmium arsenide (Cd3As2), a Dirac semimetal with promising transport properties, in particular, a low thermal conductivity and high electron mobility.

“We were pretty excited about this material, and we thought, ‘Okay, this is really a combination of these two great properties,'” Liao said. “But there is only one problem. This problem was that in addition to good electric conduction and poor thermal conduction, you also need this material to be able to generate enough voltage under a temperature gradient.”

As a semimetal, cadmium arsenide is excellent at conducting electricity very rapidly, but it only generates a very small Seebeck voltage. To create a useful voltage, Liao explained, one would need to open up a band gap.

“You want this material to have a certain energy range where the electrons cannot conduct. That’s called a band gap,” he said. Because of the gap, which essentially blocks the free flow of electrons, enough electrical “pressure” (a.k.a. voltage) can build up as a response to a temperature difference across the material. In bulk cadmium arsenide crystals, there is no band gap.

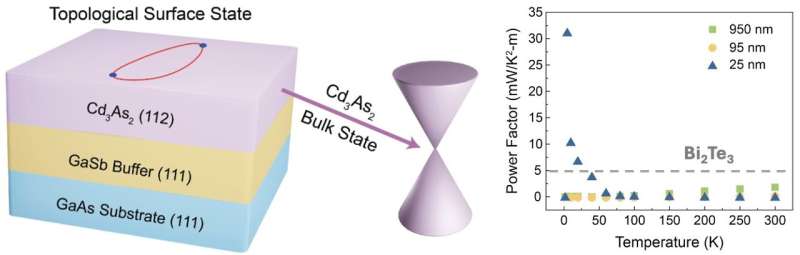

Fortunately, the team had an advantage, in the form of UCSB materials scientist Susanne Stemmer’s thin-film prowess. With expertise in molecular beam epitaxy (MBE), Stemmer’s lab is able to “grow,” molecule by molecule, high-quality materials with thicknesses ranging from a few nanometers to several micrometers. This is particularly useful in the case of cadmium arsenide, it turns out, as there are properties on the surface of the material that are distinct from those in the bulk of the crystal.

“One signature of topological insulators like this is that in addition to electron conducting states inside the bulk material, they have surface conducting channels,” Liao explained. “There are electrons that reside only on the surface of the material, and they can conduct electricity.”

To set the stage for these topological effects, the Stemmer Lab created three high-quality films grown by MBE of varying thicknesses: 950 nm, 95 nm and 25 nm.

“The high mobilities of epitaxial cadmium arsenide films allow for revealing their topological nature via quantum transport measurements,” Stemmer explained.

The team found that the thinner the material, the more evidence there was of a band gap. And, the thinner the material, the more the surface effects dominate.

“Basically, if you go to very low dimensions, quantum mechanics starts to play a role, and you can actually open a band gap just by shrinking the size,” said Liao, due to a phenomenon known as quantum confinement. They also found that the thinner the material, the higher the thermoelectric sensitivity (known as the Seebeck coefficient), resulting in more voltage in response to the temperature gradient, a response enhanced by seven times compared to the state-of-the-art material.

These quantum effects were found at near-zero temperatures, so although currently Cd3As2 thin films can’t be deployed for room-temperature or high-heat efficiency applications, Liao said, they could be more immediately useful in cryogenic environments, which exist in many applications, such as aerospace, medicine and quantum computing.

“If you’re using a very efficient, solid-state material for cooling, you won’t need dangerous and polluting refrigerants,” he said.

“Practically, it’s a very useful discovery for low-temperature, cryogenic, solid-state cooling,” he added, “but fundamentally, this work is more important because we demonstrate for the first time that this quantum confinement effect can enhance some thermoelectric properties, and also for the first time we isolated the contribution from surface states.”