Dr. Cheol-Woo Ahn, leading a research team at the Department of Functional Ceramics within the Ceramic Materials Division at the Korea Institute of Materials Science (KIMS), has developed the world’s first heat dissipation material. This material reduces hydrophilicity through a chemical reaction that forms a nanocrystalline composite layer and increases thermal conductivity by controlling point defects. This process occurs during a simple sintering process that does not require surface treatment.

The research is published in the journal Small Methods.

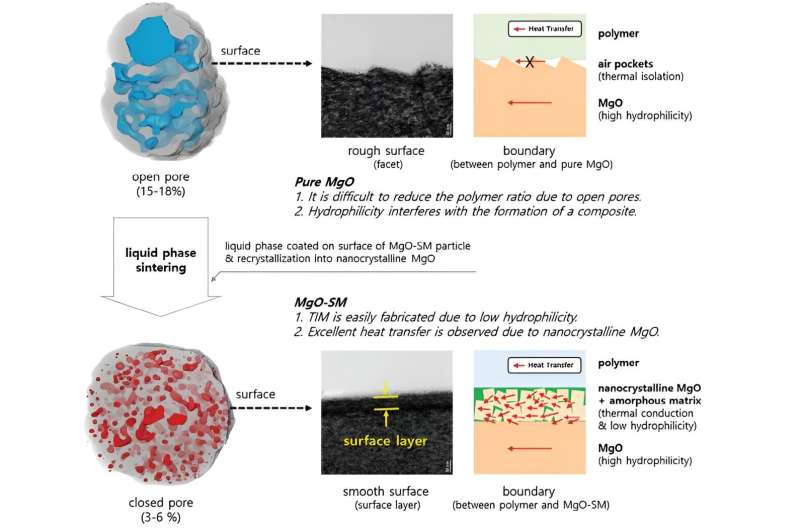

Conventional alumina filler, widely used for heat dissipation, has limitations in enhancing thermal conductivity. Therefore, there is potential in utilizing magnesia, which offers low raw material cost and excellent thermal conductivity and resistivity. However, magnesia’s high sintering temperature of 1,800°C and its hygroscopic nature, which reacts with moisture in the air, have restricted its use as a thermal filler.

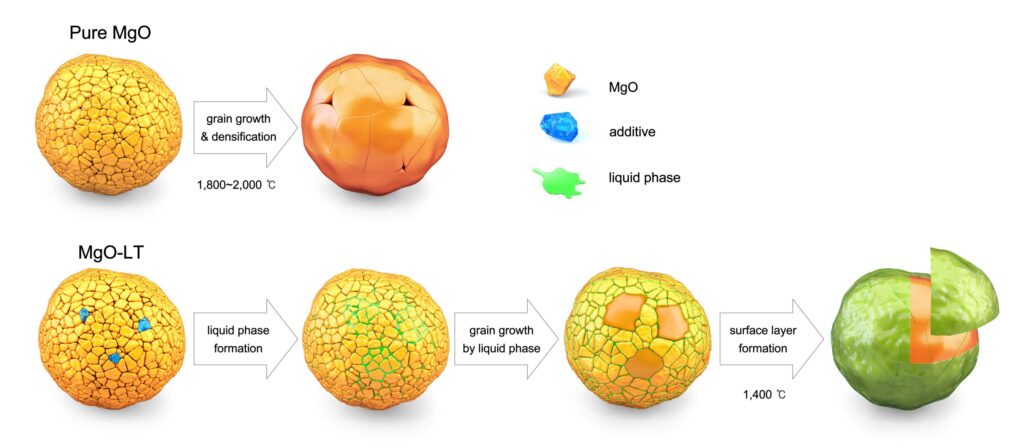

The research team utilized additives to create a thin nanocrystalline composite layer during the sintering process, forming a protective layer that reacts with moisture. They succeeded in increasing thermal conductivity by controlling defects through lower sintering temperatures. This breakthrough is seen as overcoming the limitations of existing magnesia materials and opening new possibilities for thermal management materials in next-generation industries.

In recent years, with advancements in high-tech industries, the miniaturization and multi-functionality of electronic components have posed significant challenges for thermal management. This is particularly evident in the high-capacity batteries of electric vehicles and the increased integration of electronic components, necessitating heat dissipation materials with high thermal conductivity to manage rising heat density.

Based on electric vehicle sales projections, the market for heat dissipation materials used in the thermal interface materials of electric vehicles is expected to reach approximately 9.7 trillion won in 2025. The results of this research hold significant promise in addressing moisture reaction issues and the high sintering temperatures associated with existing low-cost heat dissipation materials.

Dr. Cheol-Woo Ahn, the senior researcher stated, “We were able to address the moisture reaction issue, which causes mixing with polymers, in a straightforward manner through additives in the manufacturing process of oxide ceramic fillers. We have developed oxide fillers with high thermal conductivity by controlling defects. We anticipate that the developed low-cost, high-quality magnesia heat dissipation filler will dominate the heat dissipation ceramic material market.”