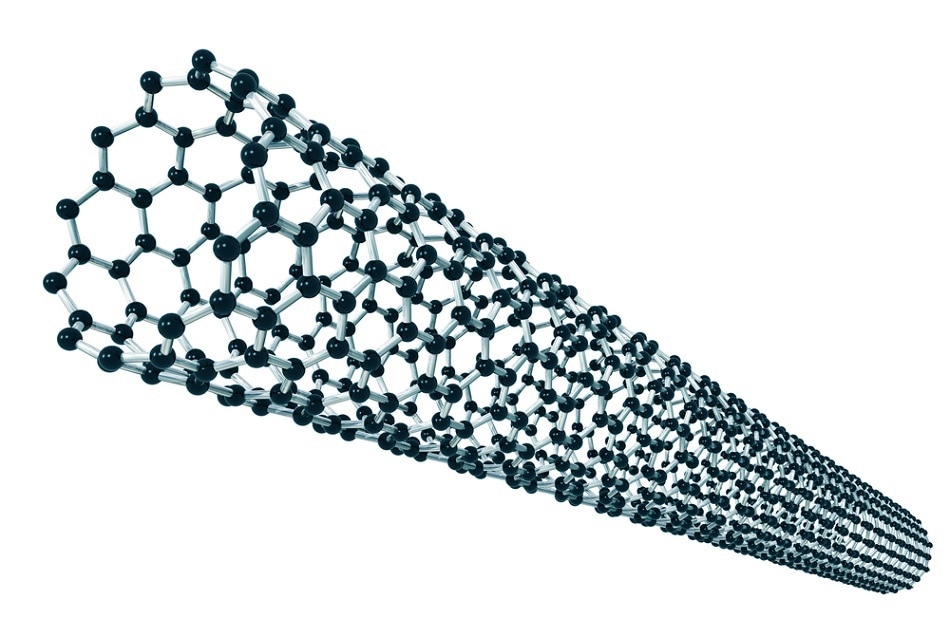

Carbon nanotubes (CNTs) have a diameter range of 0.7 to 50 nanometers and often comprise a single sheet of pure graphite that forms their cylindrical structure.

Image Credits: Paul Fleet/shutterstock.com

They exhibit extraordinary properties, including exceptional strength, thermal conductivity, and electrical conductivity. The hexagonal lattice of carbon in graphite allows the atoms within CNTs to move and vibrate freely, effectively generating electrical charges and thermal energy throughout the tube.

Due to these advantageous properties, CNTs have been extensively utilized in various industrial products, demonstrating exceptional yield strength, a higher average length-to-diameter ratio than other materials, excellent capacitance, stability at high current values, and superior inherent ballistic electron mobility. Additionally, CNTs possess a large surface area that enhances electrochemical accessibility and provides mechanical, chemical, and electrochemical stability.1

Commercially, CNTs are synthesized in two forms: Single-walled CNTs (SWCNTs) and multi-walled CNTs (MWCNTs). SWCNTs have a diameter range of about 0.4 to 2.23 nm, while MWCNTs typically range from 1 to 100 nm.2

SWCNTs and MWCNTs have applications in various fields, particularly in healthcare and drug delivery, the electronics industry, and energy storage. As experts focus on sustainable energy solutions, CNTs have emerged as a top choice for novel energy storage and conversion technologies.

Applications in Lithium-Ion Batteries

Why Do Lithium-Ion Batteries Catch Fire?

The lithium-ion battery (LIB), originally pioneered in 1912 by G.N. Lewis but not made commercially available until the 1970s, is now the fastest-growing and most promising battery technology. With the greatest electrochemical potential and highest energy density compared to other metals, LIBs provide a safe and low-maintenance option for most electronics on the market today.

LIBs consist of three basic components: two electrodes—the anode (negative electrode) and the cathode (positive electrode)—and an electrolyte that allows charged ions to flow between the electrodes, enabling charging and discharging. While LIBs offer several advantages over other energy storage chemistries, they are also relatively fragile and require a protection circuit to ensure safe operation.

Recently, researchers have shown increasing interest in developing high-capacity lithium-ion batteries, particularly those with enhanced flexibility for integration into wearable devices. CNTs have emerged as a preferred choice as a conductive agent for manufacturing the cathode and anode in LIBs.

Industrial experts have found that a very small amount of CNTs suffices to meet the electrical percolation requirements for LIB electrodes, approximately 0.5 wt.% for MWCNTs and about 0.16 wt.% for SWCNTs. These characteristics have made CNTs popular with LIB manufacturers, leading to their replacement of traditional electrode materials, such as carbon black.3

Companies like Texas-based Black Diamond Structures are working to incorporate current research on this topic into real-world applications. Through the application of groundbreaking nanotechnology, Black Diamond Structures has integrated nanomaterials into both lead-acid and lithium-ion batteries, enhancing energy storage, increasing strength, and improving performance. Their MOLECULAR REBAR® technology specifically addresses the challenge of carbon nanotubes becoming entangled, a common issue that hampers their effectiveness.

Through MOLECULAR REBAR® products, carbon nanotubes are untangled into discrete individual tubes of uniform size, allowing for their successful incorporation into lead-acid and lithium-ion batteries. This results in significantly stronger and more conductive energy storage products. For lead-acid batteries, this innovation has led to a 50 % improvement in cycle life, enhanced cold temperature performance, a 25 % increase in charge acceptance, and greater resistance to both physical and thermal misuse.

Image Credits: Coprid/shutterstock.com

Twisted CNTs: A More Efficient Energy Storage Material

Recent research has revealed that twisting SWCNTs can significantly enhance their energy storage capabilities. A novel study demonstrated that a twisted SWCNT rope modified with thermoplastic polyurethane (TPU) can store energy much more efficiently than a conventional LIB.

The gravimetric energy density (GED) of this new energy storage mechanism was found to be less than 2.1± 0.07 MJ kg−1.4 These twisted CNT ropes can store approximately 2.5 to 3 times more energy than traditional LIBs, establishing CNTs as a critical structure in the energy storage domain.

Advancements in Hydrogen Storage with CNTs

Traditional hydrogen storage techniques have faced numerous challenges and high costs. Experts are now focusing on CNTs, whose lightweight nature, stability under harsh conditions, and superior mechanical strength make them an ideal choice.

The efficiency of CNTs for hydrogen storage can be significantly enhanced through chemical pre-treatment methods. Common techniques include doping the CNTs with suitable materials and incorporating transition metals to improve hydrogen adsorption. Recent studies have shown that doping CNTs with iron (Fe) significantly improves hydrogen storage capacity.

At room temperature and pressures of 1 and 5 MPa, the hydrogen storage capacities of Fe-CNT were measured at 1.53 and 6.92 wt%, respectively. Hydrogen adsorption decreased as temperature increased, while higher pressures led to an increase in adsorption.

A comparison of pure CNTs and Fe-doped CNTs revealed that the latter exhibited superior performance, showing a 17 % increase in efficiency at 10 MPa pressure conditions. These findings demonstrate that Fe-CNTs are more effective than pristine CNTs for hydrogen storage applications due to their enhanced adsorption capacity.5

CNTs in Super-Capacitors

Supercapacitors are essential components in the energy sector, and the high conductivity of CNTs makes them suitable for this application. CNTs combined with polyaniline (PANI) can create flexible composites with excellent cyclic stability for use in supercapacitors.

Researchers have recently developed a novel method for fabricating ‘dead-weight’ free supercapacitors using electrochemical deposition of PANI onto free-standing SWCNT films. The specific gravimetric capacitance increased as the thickness of the SWCNT films decreased, reaching 541 F g−1.

Thin free-standing films of carbon nanotubes with deposited PANI showed better capacitance retention when connected through an SWCNT contact. The experimental results indicate that composites made from thin SWCNT films with a small amount of deposited PANI are most effective for energy storage, thanks to their well-structured 3D architecture and fast diffusion processes.6

Beyond traditional supercapacitors, CNTs are now integral to the development of wearable supercapacitors due to their unique one-dimensional structure, high electrical and thermal conductivity, exceptional flexibility, strong mechanical strength, and low gravimetric density. These properties make CNTs ideal for applications in emerging markets, such as smart textiles and other wearable electronics.7

CNTs in Energy Conversion Technology

Energy conversion technologies like fuel cells are receiving significant attention as experts promote sustainable energy systems. The inherent properties of CNTs make them essential materials in fuel cell fabrication, optimizing electro-catalytic reactions during charging and discharging to enhance efficiency.

CNTs have become popular catalyst support materials for polymer electrolyte membrane fuel cells (PEMFCs) due to their tubular structure, which is ideal for heterogeneous catalysis.8 Recently, researchers from the Korea Institute of Machinery and Materials (KIMM) have developed an innovative energy harvester that utilizes the motion of sodium ions to efficiently generate electrochemical energy from seawater.

This eco-friendly device employs MWCNTs and graphene oxide films as electrodes. The arrangement of ions at the cathode and anode creates a potential difference, which, in turn, produces energy.9 This application of MWCNTs in the self-chargeable energy harvester exemplifies their effectiveness in energy conversion and extraction.

Future Prospects for CNTs in Energy Storage

The future holds exciting possibilities for CNTs in energy storage applications. Hybrid aerogels that combine fullerenes and CNTs during the gelling process may enhance energy storage efficiency. While graphene-CNT hybrid aerogels have been studied, fullerene-based aerogels have yet to be fully explored. Additionally, ongoing research into scalable production methods for CNTs indicates that cost-effective solutions may become more accessible.

These developments suggest that the market for CNTs in energy storage could experience growth and commercialization in the coming years.

More from AZoNano: Carbon-Based Nanomaterials: Overcoming Challenges in Air Sensitivity for Next-Generation Batteries

References and Further Reading

- Maheswaran, R., et al. (2022). A Critical Review of the Role of Carbon Nanotubes in the Progress of Next-Generation Electronic Applications. J. Electron. Mater. https://doi.org/10.1007/s11664-022-09516-8

- Brito, C., et al. (2024). A review on carbon nanotubes family of nanomaterials and their health field. ACS omega. https://doi.org/10.1021%2Facsomega.3c08824

- Kim, J., et al. (2023). Perspective on carbon nanotubes as conducting agent in lithium-ion batteries: the status and future challenges. Carbon Lett. https://doi.org/10.1007/s42823-022-00449-0

- Utsumi, S., et al. (2024). Giant nanomechanical energy storage capacity in twisted single-walled carbon nanotube ropes. Nat. Nanotechnol. https://doi.org/10.1038/s41565-024-01645-x

- Baghai, B., et al. (2024). Hydrogen storage efficiency of Fe doped carbon nanotubes: molecular simulation study. Royal Society of chemistry. https://doi.org/10.1039/D3RA08382A

- Panasenko, I., et. al. (2022). Flexible supercapacitors based on free-standing polyaniline/single-walled carbon nanotube films. Journal of power Sources. https://doi.org/10.1016/j.jpowsour.2022.231691

- Joseph, K. et al. (2022). Carbon Nanotube Fiber-Based Wearable Supercapacitors—A Review on Recent Advances. Energies. https://doi.org/10.3390/en15186506

- Okafor, O. et. al. (2024). Surface modification of carbon nanotubes and their nanocomposites for fuel cell applications: A review. AIMS Materials Science. https://doi.org/10.3934/matersci.202402

- Korea Institute of Machinery and Materials (KIMM). National Research Council of Science & Technology. (2024). With KIMM’s new technology, electricity can be generated from seawater. [Online] EurekAlert. Available at: https://www.eurekalert.org/news-releases/1057494 (Accessed on: October 14, 2024).