Manufacturing at the nanoscale has opened up a wealth of possibilities for new technologies. From precision optics1 to smart food packaging systems2, nanoscale manufacturing is increasingly becoming a core part of industrial manufacturing technologies.

Image Credit: Rost9/Shutterstock.com

Working on the nanoscale for manufacturing poses some unique challenges. While many macroscale manufacturing methods such as lithography and additive manufacturing have been successfully translated into the world of nanoscale manufacturing,3 the demands of the precision and accuracy of the manufacturing equipment make such techniques very expensive and demanding in terms of hardware implementations.

An average atom is up to about 0.5 nm in diameter and being able to manipulate and control the arrangement of individual atoms into more complex structures would provide the ideal building capabilities for many complex nanoscale structures and devices.

One of the most popular tools for the characterization of nanoscale structures is electron microscopy. While the costs of electron microscopy instrumentation are not inconsiderable, the rich information on material structure and composition that can be captured in electron microscopy experiments has made the technique indispensable in research and development in fields from materials science to drug discovery and electronics.4

The reason behind electron microscopy’s success in nanoscience is because of its exceptionally high spatial resolution that can even be sufficient to visualize single atoms on surfaces.5 The same capabilities that make electron microscopy excellent for imaging atomic-scale objects and features also make it excellent for manipulating single atoms.

Atom Manipulation

Probably one of the most iconic electron microscopy images is that of the IBM name created on a nickel surface from 35 xenon atoms.6 The team had demonstrated that scanning tunneling microscopes (STMs) could be used to record images and pick up and move individual atoms in a shape of the researcher’s choosing.

While the interactions between the surface and the tip had originally caused some problems with scientists’ attempts to force atoms into a given arrangement of the surface, by applying a current to the tip while scanning over the surface, the atoms could be controlled and manipulated.

As electron microscopy technologies have improved and scientists have a greater knowledge of how to manipulate specific atom types, the complexity of the measurements, imaging and manipulation with STM has increased.7 Now, the challenge for researchers is to find ways not just to place a single atom on a surface but to stack and arrange atoms into complex shapes and structures.

Atomic Control

A perfect manufacturing technique has a very high degree of control with entirely predictable outcomes. Poor control in a process leads to unwanted results and, particularly if quality control requirements are stringent, leads to a large number of failed products.

Many of the applications in optics and optoelectronics are incredibly demanding in terms of the quality of the materials needed and even small imperfections and defects can lead to poor performance. Some questions for atomic engineering is how to combine multiple manufacturing steps to make large-scale assemblies and how to understand and predict the possible outcomes when the often intense and destructive electron beams interact with a sample.8

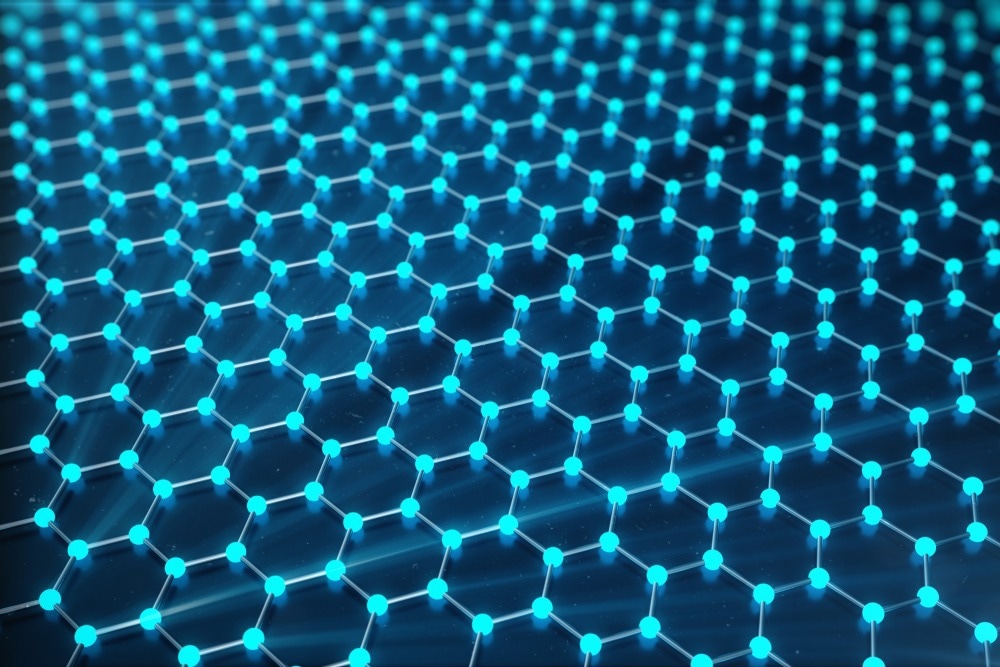

One group has been trying to understand how to bias the single-atom dynamics with electron irradiation to introduce P dopants at specific sites in graphene structures, a prototypical 2D material. Depending on the specific position of the carbon, the probabilities for various processes, such as knockout or replacement, would vary. The researchers’ could then use the carbon displacement to try and increase the probability of substitution at a particular site in the lattice.

Nanorobotics

As well as using the direct electron beam to move atoms along a sample surface, a number of nanorobotic manipulation approaches are being developed that also allow for bottom-up creation of nanoscale structures.9

One of the challenges with scanning tunneling microscopy, which was the technique used to create iconic IBM images, is that it requires the use of conductive probes and samples. The requirement for conductive materials limits the substances that can be worked with. Atomic force microscopy is more general as a technique and can also be used in non-vacuum environments, but it is still somewhat limited in its manipulation capabilities due to the relatively long imaging times. What this means is that moving atoms can be quite time-consuming.

Another approach is to combine MEMS devices for picking up the samples as grippers and to improve the adhesion of objects instead of using the electron microscope tip itself. Differently shaped tips can also alter what can be picked up with electron microscopes, and the enhanced use of virtual reality techniques is helping operators improve the precision of the movement of parts.

In conclusion, electron microscopy approaches provide powerful tools not just for the characterization of nanomaterials but also for their assembly and creation. Making nanoscale devices atom-by-atom is now completely feasible, but future work will be needed to speed up this process and improve the compatibility of manufacturing techniques with a large number of sample types.

See More: Combining AFM and Deep Learning to Improve Nanomanipulation

References and Further Reading

Zolfaghari, A., et al. (2019). Additive manufacturing of precision optics at micro and nanoscale. International Journal of Extreme Manufacturing, 1, p. 012005. doi.org/10.1088/2631-7990/ab0fa5

Park, S., et al. (2020). Nanoscale manufacturing as an enabling strategy for the design of smart food packaging systems. Food Packaging and Shelf Life, 26, p. 100570. doi.org/10.1016/j.fpsl.2020.100570

Khare, H. S., et al. (2018). Nanotribological Printing: A Nanoscale Additive Manufacturing Method. Nano Letters, 18(11), pp. 6756–6763. doi.org/10.1021/acs.nanolett.8b02505

Spurgeon, S. R., et al. (2021). Towards data-driven next-generation transmission electron microscopy. Nature Materials, 20(3), pp. 274–279. doi.org/10.1038/s41563-020-00833-z

Zhu, Y., & Dürr, H. (2015). The future of electron microscopy. Physics Today, 68(4), pp. 32–38. doi.org/10.1063/PT.3.2747

DM, E., & EK, S. (1990). Positioning single atoms with scanning tunnelling microscope. Nature, 344(April), p. 524. doi.org/10.1038/344524a0

Stipe, B. C., et al. (1998). Single-molecule vibrational spectroscopy and microscopy. Science, 280(5370), pp. 1732–1735. doi.org/10.1126/science.280.5370.1732

Su, C., et al. (2019). Engineering single-atom dynamics with electron irradiation. Science Advances, 5(5), pp. 1–12. doi.org/10.1126/sciadv.aav2252

Su, C., et al. (2019). Engineering single-atom dynamics with electron irradiation. Science Advances, 5(5), pp. 1–12. doi.org/10.1126/sciadv.aav2252