The team led by Delphine Bouilly, a professor in UdeM’s Physics Department and director of IRIC’s Electronic Nanobiosensor Design and Application Research Unit, has developed an original technique for manipulating and moving graphene, a 1-atom-thick material involved in the assembly of electronic chips, for applications in molecular diagnostics. Led by doctoral student Amira Bencherif, the study was published in the journal npj 2D Materials and Applications.

Graphene is a two-dimensional (2D) nanomaterial composed of a single layer of carbon atoms. Its physical and electronic properties make it ideal for the manufacturing of a wide range of technological devices, such as biosensors.

It can be synthesized quickly and in large quantities on a copper surface, but the graphene ribbons must then be transferred from the metal surface to production disks (called wafers) to enable the simultaneous assembly of several chips. This transfer step is critical, and represents a major challenge for the large-scale production of devices based on 2D nanomaterials such as graphene.

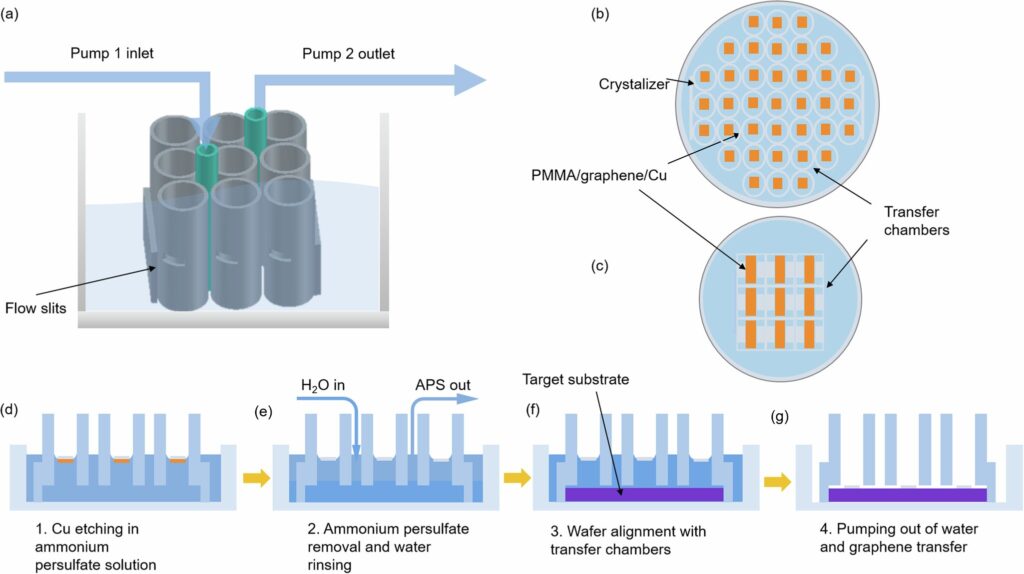

To meet this need, Bouilly’s team has designed an original and novel graphene transfer technique. The transfer device consists of a network of glass chambers in which graphene-coated copper sheets are placed. By means of a pumping system, the chambers are filled, then emptied, with various solutions that dissociate the graphene from the copper and transfer it to a production wafer previously aligned with the chambers. The whole process is automated, with no manual handling, much like a miniature assembly line.

New manufacturing possibilities

The technique developed by Bouilly’s team offers several important advantages. It automates a manual method that used to require a great deal of dexterity, making it faster and easier to perform. The device also enables several graphene ribbons to be transferred in parallel, a key aspect in improving transfer speed and volume. In addition, the system enables vertical assembly of multiple graphene layers. Last but not least, automated parallel transfer saves on graphene usage by limiting losses.

The system will facilitate the manufacturing of devices based on graphene and other 2D materials. At the same time, it will enable production volumes to be increased. The use of these devices as biosensors is currently being developed by the Bouilly laboratory, notably for the diagnosis of cancers and other diseases.