Plastics, fuels, and many industrial materials are still largely derived from fossil fuels. These resources contribute to greenhouse gas emissions and long-term environmental degradation.1 As the push for renewable alternatives grows, researchers are exploring bio-derived materials that offer performance without the environmental cost.

Image Credit: Choksawatdikorn/Shutterstock.com

One promising candidate is cellulose nanocrystals (CNCs). Derived from plant-based biomass, CNCs offer a unique combination of strength, flexibility, biodegradability, and low environmental impact. These properties make CNCs increasingly attractive as substitutes for petroleum-based plastics, resins, and even components in energy systems.2

This article explores CNCs, how they’re made, and whether they can realistically replace fossil fuels in key applications such as packaging, electronics, and sustainable materials manufacturing.

What Are Cellulose Nanocrystals?

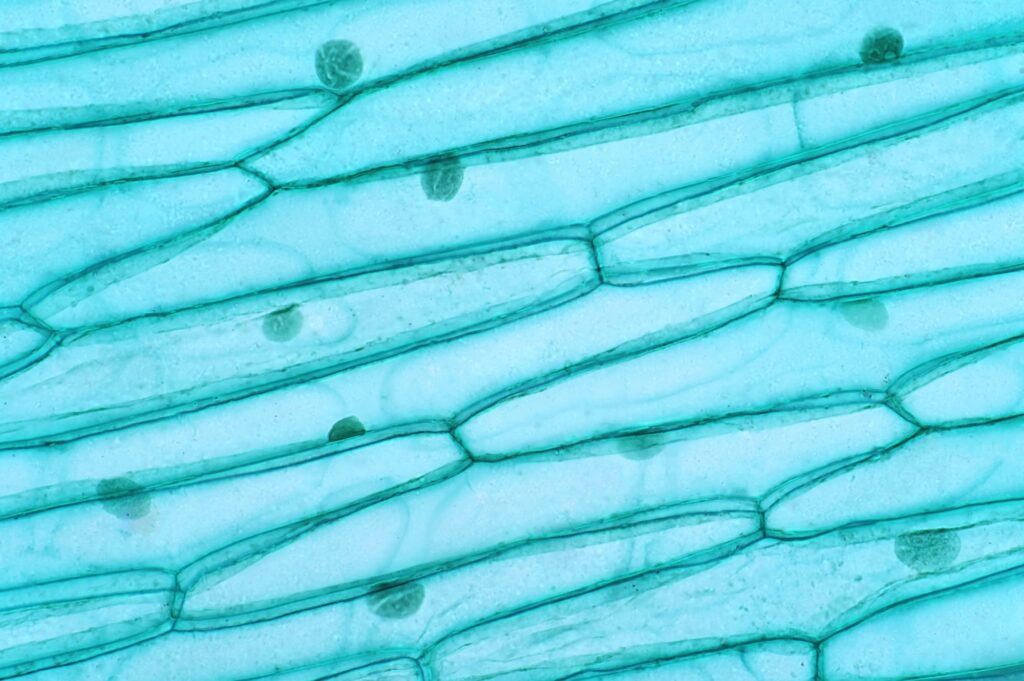

Cellulose nanocrystals (CNCs) are rod-shaped, nanoscale particles extracted from cellulose, a naturally abundant polysaccharide found in plant cell walls and other biological materials. CNCs are typically between 1 and 100 nanometers in diameter and are formed by isolating the crystalline regions of cellulose fibers.

Structurally, CNCs consist of β(1→4)-linked anhydroglucopyranose units. Each unit is rotated 180 degrees relative to the next, forming linear chains that are stabilized by intramolecular hydrogen bonds. These bonds, primarily between hydroxyl groups on the glucose rings, contribute to the material’s rigidity and high crystallinity.3

CNCs can be derived from a wide range of natural sources. Common plant-based feedstocks include wood pulp, cotton, hemp, jute, and other lignocellulosic biomass. They can also be sourced from algae, bacteria such as Komagataeibacter xylinus, and marine animals like tunicates, which produce cellulose with high crystallinity.5

Synthesis of CNCs

Isolation from Natural Sources

CNCs are typically isolated from cellulose-rich biomass in two stages: pretreatment and crystallization.

First, purification removes non-cellulosic components like lignin and hemicellulose. The Kraft process is commonly used for plant sources, where sodium hydroxide (NaOH) and sodium sulfide dissolve lignin. This is often followed by bleaching with chlorine dioxide (ClO2). However, the environmental impact of these chemicals has raised concerns.

For algae, bacterial, and animal sources, a pre-hydrolysis kraft cooking–bleaching process is usually used. Some bacteria can also produce highly crystalline cellulose directly in the form of flat pellicles, bypassing extensive purification steps.

Acid Hydrolysis

Acid hydrolysis is the most widely used method for producing CNCs. It breaks down cellulose fibers by selectively removing amorphous regions, leaving behind crystalline nanostructures. Sulfuric acid is also commonly used, though it can introduce surface charges that affect CNC behavior.6 The typical yield ranges from 58 % to 76 %, depending on the source and conditions.

Mechanical and Enzymatic Methods

Mechanical techniques like microfluidization, ultrasonication, and ball milling are also used to extract CNCs. These methods avoid harsh chemicals but require high energy input.

Enzymatic extraction offers a greener alternative. Cellulases, such as endoglucanase and exoglucanase, selectively hydrolyze cellulose. Endoglucanase breaks down amorphous domains, while exoglucanase cleaves crystalline chains, yielding CNCs with minimal environmental impact.

Ionic Liquid Treatment

A newer method involves using ionic liquids, salts in liquid form at room temperature, to dissolve and regenerate cellulose. Ionic liquids like 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) can extract CNCs efficiently and are recyclable. However, high costs and limited scalability currently limit industrial use.7

Nanocrystal Assemblies: Gaining Power in Numbers

Applications: Replacing Fossil Fuel–Derived Materials with CNCs

CNCs offer high strength, crystallinity, and gas barrier properties, making them suitable for a range of industrial applications.

In packaging, CNCs are used as nanofillers in polymer composites to improve strength and biodegradability. Their dense crystalline structure and hydrogen bonding provide excellent oxygen barrier properties. This helps extend shelf life and protect contents from external contaminants.

One study showed that adding 2 wt.% CNCs to a green composite film improved tensile strength by 40 % and Young’s modulus by 78 %. It also reduced water absorption, with percentage swelling dropping from 818 % to 537.85 %.8

CNCs also show promise in energy storage. They are used in aerogels and films as substrates for flexible electrodes and superconductors. Their high mechanical strength and flexibility make them ideal for these roles.

CNC-derived porous carbon materials are used in lithium–sulfur (Li–S) batteries to provide a conductive framework. When doped with nitrogen and sulfur, CNC-based carbon materials show large surface areas and pore volumes, which enhance energy storage performance.9

In the biomedical field, CNCs are used for skin therapy, wound dressings, and targeted drug delivery. Their biocompatibility and tunable properties also support their use in cartilage implants, artificial blood vessels, and tissue engineering.10

CNCs have shown strong potential to replace fossil fuel-derived materials across multiple sectors. However, some modification techniques and processing methods remain costly. As a result, industries may continue to use conventional materials for economic reasons. If production becomes more affordable, CNCs could play a larger role in sustainable manufacturing.

For more on renewable materials and emerging applications in clean tech, packaging, and energy storage, see:

References and Further Reading

- Suman, T. et. al. (2020). Characterization of petroleum-based plastics and their absorbed trace metals from the sediments of the Marina Beach in Chennai, India. Environ Sci Eur 32, 110. Available at: https://doi.org/10.1186/s12302-020-00388-5

- Wu, Y. et. al. (2022). Advanced nanocellulose-based gas barrier materials: Present status and prospects. Chemosphere, 286, 131891. Available at: https://doi.org/10.1016/j.chemosphere.2021.131891

- Calle‐Gil, R. et. al. (2022). Cellulose nanocrystals in sustainable energy systems. Advanced Sustainable Systems, 6(4), 2100395. Available at: https://doi.org/10.1002/adsu.202100395

- Masaoka, S. et. al. (1993). Production of cellulose from glucose by Acetobacter xylinum. Journal of fermentation and bioengineering, 75(1), 18-22. Available at: https://doi.org/10.1016/0922-338X(93)90171-4

- Zhao, Y. et. al. (2014). Excellent chemical and material cellulose from tunicates: Diversity in cellulose production yield and chemical and morphological structures from different tunicate species. Cellulose, 21, 3427-3441. Available at: https://doi.org/10.1007/s10570-014-0348-6

- Ng, H. et. al. (2015). Extraction of cellulose nanocrystals from plant sources for application as reinforcing agent in polymers. Composites Part B: Engineering, 75, 176-200. Available at: https://doi.org/10.1016/j.compositesb.2015.01.008

- Trache, D. et. al. (2017). Recent progress in cellulose nanocrystals: sources and production. Nanoscale, 9(5), 1763-1786. Available at: https://doi.org/10.1039/C6NR09494E

- Yadav, M. et. al. (2012). Cellulose Nanocrystal Reinforced Chitosan Based UV Barrier Composite Films for Sustainable Packaging. Polymers. 12(1):202. Available at: https://doi.org/10.3390/polym12010202

- Kim, J. et. al. (2019). Nanocellulose for energy storage systems: beyond the limits of synthetic materials. Advanced Materials, 31(20), 1804826. Available at: https://doi.org/10.1002/adma.201804826

- Fahma, F. et. al. (2021). Nanocellulose as a new sustainable material for various applications: A review. Archives of Materials Science and Engineering, 109(2). Available at: https://doi.org/10.5604/01.3001.0015.2624