A research team, led by Professor Seungho Cho in the Department of Materials Science and Engineering at UNIST has unveiled a novel catalyst for the effective and simultaneous removal of nitrogen oxides (NOx), carbon monoxide (CO), ammonia (NH3), precursors to fine dust formation.

This breakthrough is the result of collaborative research with Dr. Hong-Dae Kim from the Korea Institute of Industrial Technology (KITECH) and Dr. Wang Young Kim from the Korea Institute of Energy Research (KIER). The study is published in the journal ACS Nano.

Particularly concerning is NOx, with global emissions having increased to approximately 100 million tons per year, posing significant toxicity risks and prompting stricter environmental regulations. To mitigate such emissions, NH3 is introduced as a reducing agent to convert harmful NOx into harmless nitrogen gas (N2) via a chemical reaction facilitated by catalysts.

However, excess NH3 that does not engage in the reaction is subsequently released. To address this, a second catalyst is typically employed to remove residual NH3 by reacting it with CO in the exhaust gases. This conventional approach demands two types of catalysts, which is less economical and requires more space.

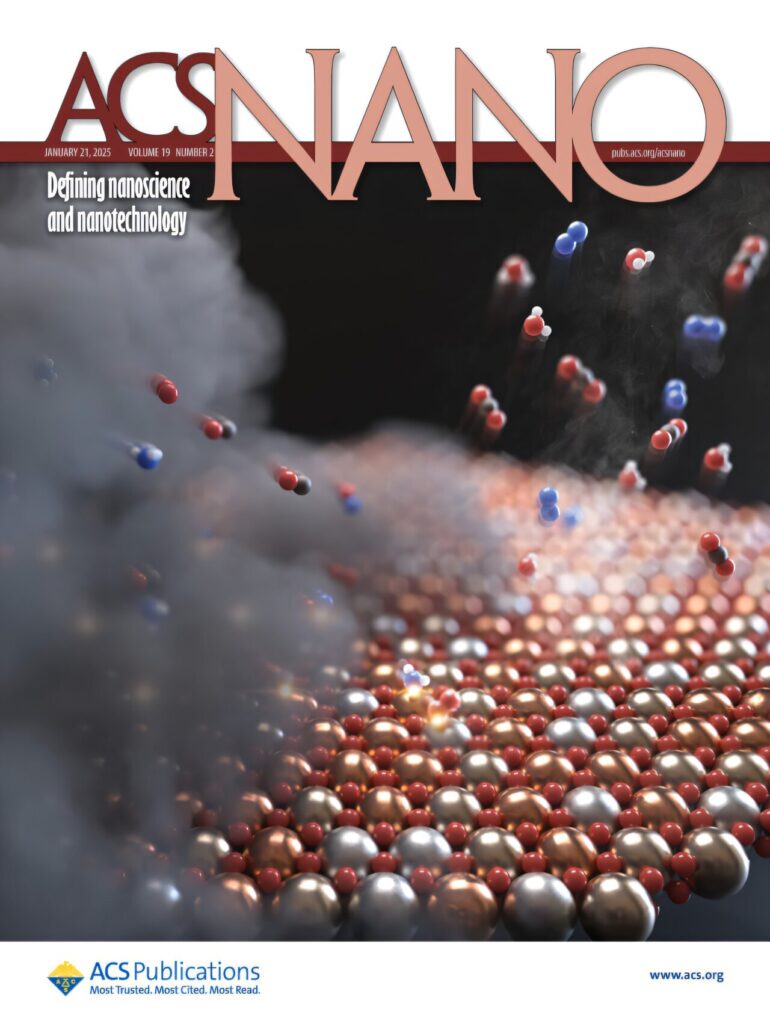

The newly developed catalyst, based on a copper–nickel–aluminum (Cu–Ni–Al) mixed metal oxide (MMO), effectively performs the functions of both catalysts, allowing for the simultaneous removal of all three precursor types. It achieved impressive conversion rates of 93.4% for NOx, 100% for CO, and 91.6% for NH3, with a nitrogen selectivity of 95.6%. High selectivity indicates that harmful by-products, such as nitrous oxide (N2O), are minimized.

The research team also identified the optimal gas mixture ratio to maximize the catalytic performance. They elucidated the reaction mechanisms behind the simultaneous reduction for the first time and proposed the optimal NH3 injection ratio in environments with fluctuating CO levels.

Additionally, the team validated the performance of the CuNiAl–MMO nanostructure catalyst for commercialization in practical simultaneous removal reaction (SRR) applications across various industries. In these settings, powder catalysts encounter significant challenges, including severe pressure drops and sintering due to high flow rates in industrial environments.

To tackle these issues, the catalyst was mass-produced and coated onto the surface of a glass fiber sheet. This approach ensures that the catalyst can withstand demanding conditions while maintaining high conversion rates during performance testing.

Additionally, the team validated the performance of the CuNiAl–MMO nanostructure catalyst for commercialization. Despite the challenges faced by powder catalysts, such as severe pressure drops and sintering at high flow rates during testing under real industrial conditions, the catalysts exhibited durability and achieved high catalytic conversion rates, highlighting their potential for the simultaneous removal of NOx, CO, and NH3 in various industries.

Professor Cho stated, “The developed catalyst operates efficiently at a relatively low temperature of 225°C and demonstrates excellent performance in its molded form, making commercialization promising.”