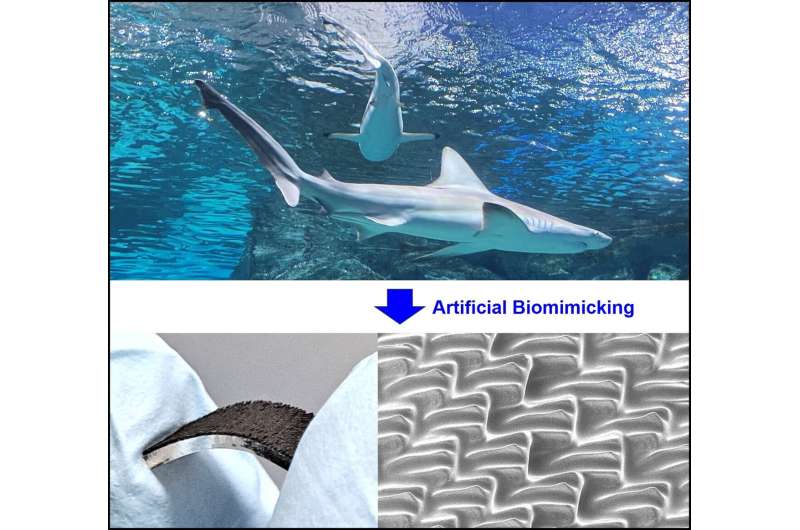

Sharks in nature swim at high speeds in a deep ocean due to their high drag reduction ability. Water flows around the sharkskin become disrupted by staggered and overlapping microscale structures named denticles. In addition to this surface roughness, water slips at a fluid-solid interface with multiple groove-like microriblets on individual microdenticles.

Furthermore, the sharkskin exhibits high penetration resistance because of its quad-layered structure from enamel to dermis. There are hard-on-soft layered mechanical gradients from the outside to the inside of the sharkskin.

This unique and functional sharkskin found in nature motivates this study, published in Advanced Materials, the first to microfabricate three-dimensional (3D) overlapped microdenticles with sharp microriblets. The 3D artificial sharkskin was able to achieve multiple functionalities by mimicking morphological and material characteristics of the natural sharkskin.

Many previous studies have been conducted to develop artificial sharkskin that mimics natural sharkskin with functional advantages. However, it has been difficult to form 3D overlapping morphology while maintaining the shape of microriblets on the microdenticles. Undesired thermal deformation continues to be an issue for the polymer-based microdenticles periodically arranged with narrow interspacing.

To solve this problem, Wie and his colleagues fabricated riblet-textured microdenticles using a composite of magnetic particles and elastomeric polymers. Next, 3D microdenticles were induced to bend until they overlapped each other under an external magnetic field.

While an interesting concept, there is a need to shape-fix this magnetic overlapping to functionalize sharkskin under the removal of the magnetic field. “We newly developed a chemical shape-fixation strategy to fabricate 3D staggered-overlapped sharkskin,” said Jeong Jae Wie, a professor in the Department of Organic and Nano Engineering at Hanyang University.

“The microdenticles need to be actuated in reverse direction to coat a thin layer of a liquid resin of polymer on the sharkskin. After changing actuation in a forward direction, a thin polymer layer is cured, completing microfabrication of 3D artificial sharkskin with immobilized magnetic overlapping,” said Jeong Eun Park, a first author in the published study.

“A unique point of this work is the ability of their 3D artificial sharkskin to demonstrate multiple functionalities while other studies have only been able to document one or two features,” said Wie’s collaborator, Seung Goo Lee of University of Ulsan.

The research team first showed drag reduction, a representative functionality of natural sharkskin. 3D artificial sharkskin with hydrophobicity reduces drag when water flows in the frontal direction of the microriblets.

“In our hydrophobic sharkskin, micro-sized air bubbles are trapped among overlapped microdenticles, causing slip of water layer on the air bubbles,” added Wie’s collaborator, Rhokyun Kwak of Hanyang University.

In addition to this drag reduction functionality, their 3D artificial sharkskin exhibits low friction when scratching sample in the frontal direction and high mechanical robustness with structural recovery, owing to the architecture of staggered-overlapped microdenticles.

“Interestingly, these functionalities could be improved by coating the mechanically soft polymer-based sharkskin with nanoscale thin layer of mechanically brittle material. This concept is motivated by the hard-on-soft layered structure of the natural sharkskin,” added Wie.

“Typically, mechanically soft film has high surface friction against contact with surrounding obstacles. However, in this work, the coefficient of friction decreases when coating sharkskin with a thin ceramic because hard and flexible characteristics coexist on this tri-layered sharkskin,” explained Wie’s collaborator, Sanha Kim of Korea Advanced Institute of Science and Technology.

Subsequently, Wie’s team coated the tri-layered sharkskin with a thin metal. In a test of indentation, quad-layered sharkskin exhibited enhanced hardness and recoverable work, when compared to the noncoated polymeric sharkskin. Especially in the feature of structural recovery, “Recoverable work can be stored in the bent microdenticles while the thin layers of mechanically brittle materials may enhance the elastic strain energy of the 3D artificial sharkskin,” added Kim.

Furthermore, for microtextured electronic applications, when the polymer-based sharkskin is coated with an electrically conductive MXene material, it has a low electrical resistance of 5.3 Ω.

“MXene-coated sharkskin enables joule heating with high temperature even when a low voltage is applied (e.g., 230°C at 2.75 V). In addition, because of the hydrophilicity of MXene material, wetting properties of sharkskin also changes from hydrophobic to hydrophilic,” said Wie’s collaborator, Tae Hee Han of Hanyang University.

“This research is the first to report on multiple functionalities demonstrable by the 3D artificial sharkskin, with many potential applications in a variety of fields,” said Lee. For example, if the technology of this multifunctional artificial sharkskin was to be utilized in the shipping industry, economic efficiency could be generated by reducing fuel consumption and increasing the service life of the ship.

“As for future applications, ships with our 3D artificial sharkskin can be expected to fast navigate with reduced drag, less friction in contact with surrounding obstacles, and less damage from external impacts in the ocean,” added Wie.