A novel nanoparticle spray coating process has been shown to all but eliminate the growth of some of the world’s most dangerous bacteria in air filtration systems, significantly reducing the risk of airborne bacterial and viral infections.

That’s the principal finding of a study, led by researchers from IMDEA Materials Institute in collaboration with scientists from the Networking Biomedical Research Center in Respiratory Diseases (CIBERES) and Rey Juan Carlos University (URJC) in Madrid, Spain. The study was published in Materials Chemistry and Physics.

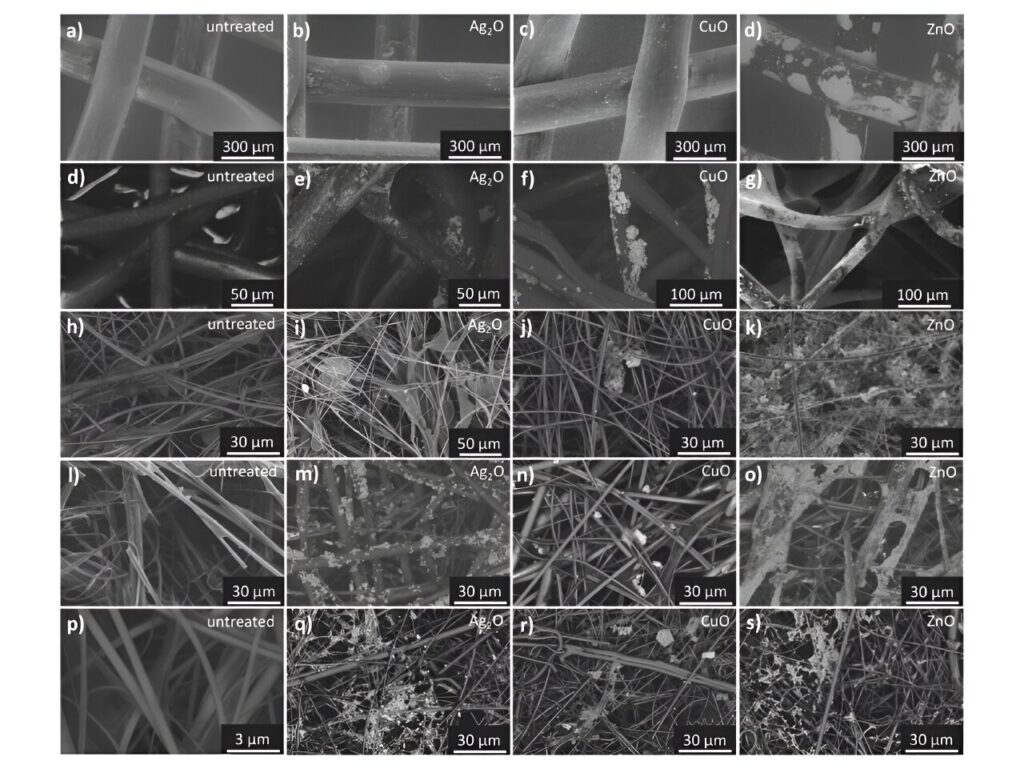

The study, “Control of microbial agents by functionalization of commercial air filters with metal oxide particles,” tested various spray coatings of silver (Ag2O), copper (CuO) and zinc (ZnO) oxides as low-cost antiviral and antibacterial filters when applied to commercially available air filtration systems.

The authors found that both the Ag2O and CuO compounds used were shown to have a total antiviral activity greater than 99%, with the Ag2O filter extract also demonstrating a complete prevention of targeted bacterial growth throughout the 24-hour incubation period measured by the study.

The study’s findings could prove relevant in preventing the spread of a wide number of respiratory infections. However, researchers focused specifically on the antimicrobial properties of metal oxide particles against two specific respiratory pathogens: Streptococcus pneumoniae and Pseudomonas aeruginosa.

“S. pneumoniae and P. aeruginosa are considered among the top five bacterial pathogens leading to death worldwide,” explains IMDEA Materials researcher Dr. Mónica Echeverry-Rendón. “S. pneumoniae is the major cause of community-acquired bacterial pneumonia, acute otitis media in children and non-epidemic meningitis.

“P. aeruginosa, meanwhile, is commonly associated with recurrent exacerbations associated with chronic infections in patients with cystic fibrosis and bronchiectasis.”

The study was conducted in conjunction with Spanish air filter manufacturer Venfilter, which supplied five commercially available filters for testing.

Air filtration is one of the most commonly used methods to ensure indoor air quality. Its efficacy has been well-established in capturing airborne pathogens and ensuring adequate air sterility in controlled environments.

However, after long-term use, microorganisms harmful to human health, such as fungal spores and bacteria can accumulate and even thrive within untreated filters.

During the last two decades, several species of bacterial spores have been detected in such environments, including Propionibacterium, Staphylococcus and Legionella. A wide variety of harmful fungus species have also been identified, such as Aspergillus, Penicillium and Cladosporium.

After an extensive preparation period, the oxide powders utilized in the study were sprayed directly onto the filter surfaces, which were then characterized and biologically assessed.

In recent years, metal oxide nanoparticles have shown positive results in inhibiting bacterial growth and challenging antibacterial resistance. The good results encourage further study on the subject to learn more about the mechanisms between particles and microorganisms.

Not only were the oxides tested for their antibacterial and antiviral efficacy, but their spray application process was also shown to have no negative effects on filtration efficiency, or on the underlying microstructure of the filter itself.

While the study’s initial results are extremely promising, further testing will need to be conducted to confirm and evaluate the findings.

“Overall, this work presents a partial preliminary evaluation of spray-coating as a low-cost, simple and versatile post-manufacturing process of air filters that can be applied to commercial purposes,” concludes Dr. Echeverry-Rendón.

“However, although the achievements reached up to this point are very significant at a scientific level, there is still a long way to go before it will be possible to commercialize them at an industrial level.

“Different aspects and further tests will need to be considered in future works…so that a complete characterization of coating effectiveness and filter performance, over time, and using real-size filter prototypes with sealed frames, can be carried out.”