Over the past few decades, material scientists and chemists have been working on designing increasingly sophisticated materials for a wide range of technological and scientific applications. These materials include synthetic polymers and hydrogels that could be introduced inside the human body as part of medical interventions.

Researchers at the Leibniz Institute of Polymer Research Dresden, Technische Universität Dresden and other institutes in Germany recently designed new fully synthetic materials with a dynamic DNA-crosslinked matrix that could prove useful for the creation of organoids (artificial organs) and other bio-mimetic systems. These materials, introduced in Nature Nanotechnology, are versatile, programmable and relatively inexpensive, making them advantageous for medical and biological research.

“Polymer chemistry can create materials with wonderful properties,” Elisha Krieg, one of the researchers who carried out the study, told Phys.org. “Think of everyday products like toys and packaging, but also bullet-proof vests, parachutes, medical implants, etc. But these materials are very static—it is not easy to change their properties, once broken they cannot heal themselves, and their characteristics are difficult to predict. Our group tries to make materials that are more akin to living matter: adaptive, self-healing, and programmed to fulfill specific functions.”

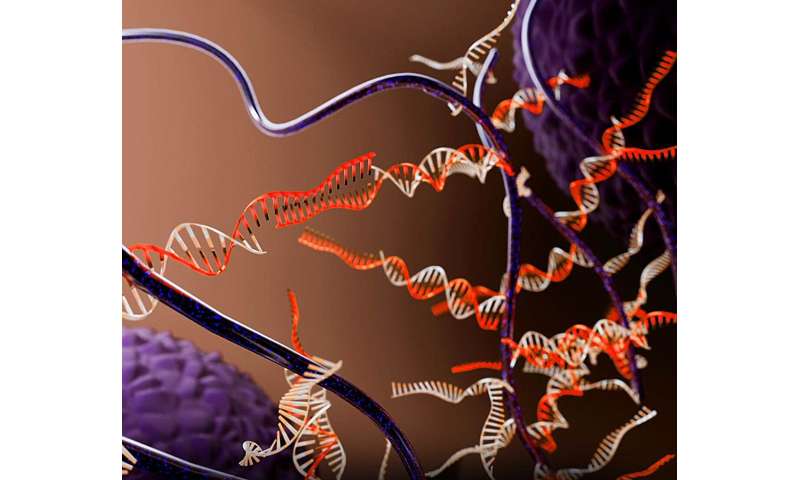

The field of DNA nanotechnology, first established by Ned Seeman, focuses on the design and manufacturing of artificial DNA structures with possible biomedical and biophysical applications. Past DNA nanotechnology studies showed that DNA can be re-programmed to control the properties of matter at a nanometer scale.

The recent work by Krieg and his colleague Yu-Hsuan Peng builds on previous research efforts in this field. Its objective was to create a soft hydrogel matrix that could host living cells and could thus be used to engineer tissue, organoids, medical implants, and other biophysical systems.

-

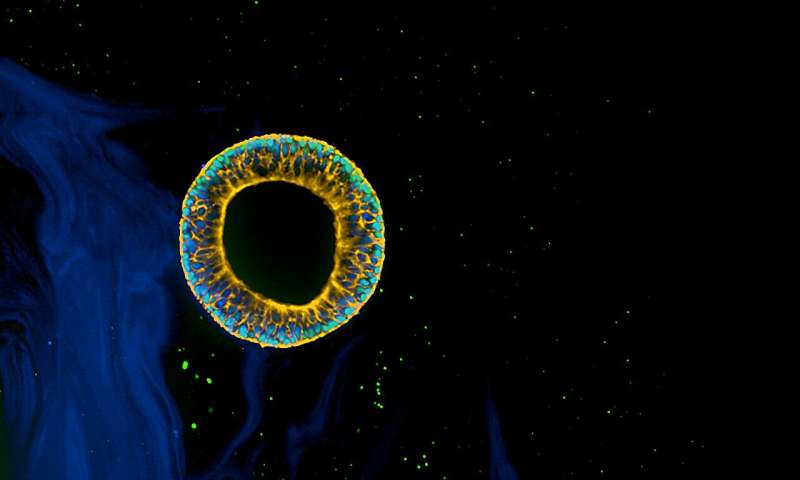

Human induced pluripotent stem cell cyst in DyNAtrix. Credit: Elisha Krieg and Yu-Hsuan Peng

-

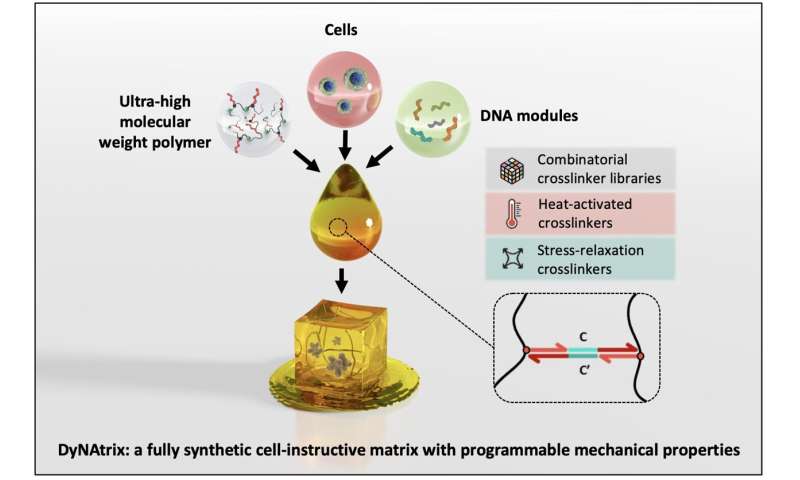

Printing of DyNAtrix. Credit: Elisha Krieg and Yu-Hsuan Peng.

“We hoped that by using principles of DNA nanotechnology, we could precisely control the properties of our soft material to optimally support cells and guide their development,” Krieg explained. “Our goal was to create a material that is fully synthetic, biocompatible, and—most importantly—its mechanical behavior should be adjustable without drastically changing its chemical composition. Last but not least, it was important to us for the material to be inexpensive, as we hoped it would be applied by many other groups in the future.”

To create a material that is versatile, synthetic, biocompatible, programmable and affordable, the researchers merged two different components. The first are heavy biologically functional polymer chains.

“These polymer chains serve as a structural scaffold for the material,” Krieg said. “They have DNA side chains that allow further DNA-based modules to integrate into the material, cross-link the polymer, and supplement it with specific functions.”

The second component of the team’s material is comprised of unique DNA modules. These modules are plugged into the material to program its properties and characteristics, allowing it to perform in specific ways,

“One key innovation was our use of DNA-based ‘libraries’—complex mixtures of DNA strands—which make cross-linking highly efficient,” Krieg said. “The sequences of the DNA libraries also control important characteristics of the material, such as the plasticity and stiffness at different temperatures.”

The dynamic DNA-crosslinked matrix created by Krieg and his colleagues, dubbed DyNAtrix, could be used to culture a variety of cells in a laboratory setting, including human pluripotent stem cells and organoids. Remarkably, their material is also self-healing, and can easily be integrated with 3D printing technology to produce a variety of complex 3D tissues and structures.

“Culturing cells in DyNAtrix can help answer questions in developmental biology, it could be used to culture tissues for regenerative medicine, or to test the effect of specific drug candidates with patient-derived cells. My hope is that testing drugs in an in-vitro cell culture system will one day entirely replace animal testing.”

-

Credit: Elisha Krieg and Yu-Hsuan Peng

-

Artist impression of DNA crosslinked polymer network between cells. Credit: Elisha Krieg and Yu-Hsuan Peng.

The new material introduced by this team of researchers has the potential to soon advance biomechanical, biophysical and biomedical research. DyNAtrix is fully synthetic, programmable, easy to reproduce on a large-scale and can be adjusted with high precision. It could also be easier to use in clinical settings compared to animal-derived materials, such as Matrigel (i.e., a matrix extracted from mouse tumors cells that is often used to culture cells in the lab).

In their next studies, Krieg, Peng, and their colleagues plan to further examine the practical applications of their matrix. For instance, they will start collaborating with cell biologists, helping them to use DyNAtrix to tackle specific research problems.

“The adjustable mechanical properties of DyNAtrix make it particularly interesting for answering questions in the field of mechanobiology, such as: how do mechanical characteristics (stiffness, viscosity, plasticity) affect the development of cells? What relevance do these effects have in a living organism? What relevance do they have in diseases like cancer? And how exactly does the mechanical environment stimulate a response in living tissues?” Krieg added.

“Work in our lab is currently focused on extending the capabilities of DyNAtrix. For instance, by plugging in fluorescent force sensors, we hope that mechanical interactions between cells and their environment can be quantified in the microscope.”

The DyNAtrix matrix is still at its early stages of development, as it still requires researchers to manually add DNA modules to induce changes in a material’s properties. In the future, the team hopes to further advance its composition and performance, for instance by using more sophisticated DNA-based reaction networks that would allow it to autonomously respond to the behavior of cells.