Technology for converting solar energy into thermal energy is ever evolving and has numerous applications. A breakthrough in the laboratory of Professor My Ali El Khakani at Institut national de la recherche scientifique (INRS) has made a significant contribution to the field.

Professor El Khakani specializes in plasma-laser processes for the development of nanostructured materials. He and his team at the Énergie Matériaux Télécommunications Research Center have developed a new photothermal material that converts sunlight into heat with unmatched efficiency. The results of their work were published in the journal Scientific Reports.

For several decades, stoichiometric titanium oxides have been known for their exceptional photocatalytic properties. A sub-stoichiometric form of this material, characterized by a slight deficiency in oxygen atoms, is referred to as “Magnéli phases,” with specific compositions exhibiting distinct properties.

Among these phases, Ti4O7 stands out as the variant offering the most compelling electrical, chemical, and catalytic properties. While its photothermal behavior has only been explored in recent years, groundbreaking research by Professor El Khakani’s team has unveiled the unparalleled potential of Ti4O7 thin films for super-efficient photothermal conversion.

Pushing the limits of materials

One of the main constraints on the potential use of Ti4O7 lay in the synthesis process and the final form of the material obtained.

“Traditionally, Ti4O7 has been synthesized in powder form using thermal reduction methods. This approach prevents the attainment of the pure phase of the material, making it difficult to control its composition, morphology, and nanostructure,” says Loick Pichon, a Ph.D. student at INRS and lead author of the publication.

“These thermal reduction methods typically yield mixed phases with several chemical compositions, which limits access to the pure material’s full potential, particularly its electrical conductivity.” Moreover, the powder produced is generally compacted into pellets, greatly limiting the size of the resulting electrodes to a few centimeters at most.

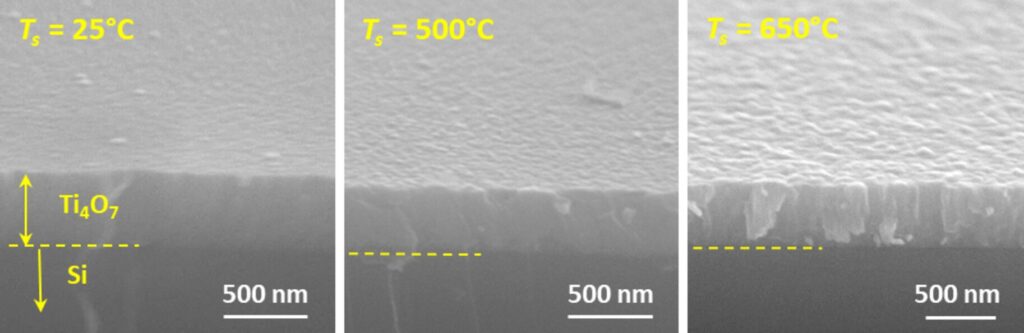

Professor El Khakani and his team turned to a technique known as magnetron sputtering (or RF-magnetron plasma) to deposit thin films of this material as coatings. This thin film deposition process is commonly used in the semiconductor industry.

“The Ti4O7 coating deposited through this method (films a few hundred nanometers thick) completely changes the surface properties of the substrate, which can otherwise vary in size or material composition, ranging from metal plates to silicon wafers or glass plates,” explains Professor El Khakani.

“Scientifically, the results of our work have made a major contribution because they establish for the first time the fundamental relationship between the optical absorbance capacity of Ti4O7 films and their photoconversion efficiency,” adds Professor El Khakani.

A wide range of applications

By enabling the controlled deposition of Ti4O7 films on various substrates, INRS researchers are opening the door to numerous impactful applications. Ti4O7 coatings are poised to play a key role in the development of high-performance anodes for the decontamination of water containing persistent pollutants.

These corrosion-resistant and highly conductive electrodes are also in high demand for electrochemical processes involved in hydrogen and ammonia production, two important economic sectors in Québec. With their exceptional photothermal conversion capabilities, these coatings are also ideal for manufacturing smart heating windows, offering substantial benefits in terms of cost savings and energy efficiency.

“The ability to create thin photothermal coatings on reasonably sized surfaces holds particular promise for passive desalination in niche applications, using only direct sunlight and requiring no external electrical energy input, unlike the commonly used reverse osmosis process,” concludes Professor El Khakani.