Researchers at The University of Texas at Dallas have invented a new, inexpensive method for fabricating artificial muscles for potential use in robots, in comfort-adjusting jackets that become more thermally insulating as the surrounding air becomes colder, and as mechanical energy harvesters.

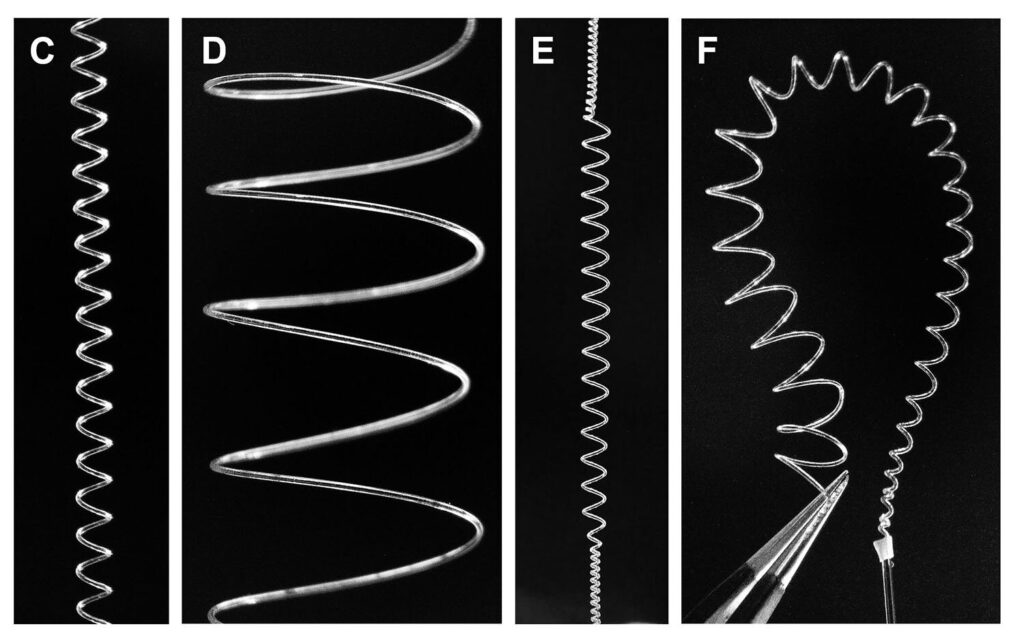

In a study published in the March 7 issue of the journal Science, UT Dallas researchers and their collaborators describe their mandrel-free method for making spring-like, thermally driven polymer muscles that can stretch 97% of their original length and have a spring index over 50.

The spring index describes the ratio of a spring’s mean diameter to the diameter of its component fiber or wire. Springs with a small spring index are tightly wound and stiffer than those with a higher index, which are more loosely wound and more flexible, such as a Slinky toy.

Dr. Ray Baughman, director of the Alan G. MacDiarmid NanoTech Institute at UT Dallas and the senior and co-corresponding author of the study, is a pioneer in creating coiled artificial muscles from various materials, including polymer fibers and carbon nanotubes. He and other researchers previously have made high-spring-index coiled muscles by wrapping such fibers, or yarns, around a mandrel, or a spindle, to form the coil.

“The problem has been that there are no process reports for making mandrel-free, large-spring-index yarns other than to dissolve the mandrel after muscle coiling, which wastes the large-diameter polymer fiber that is typically used as a mandrel and creates a waste stream,” said Baughman, a Robert A. Welch Distinguished Chair in Chemistry in the School of Natural Sciences and Mathematics.

Dr. Mengmeng Zhang, a research scientist in the NanoTech Institute and lead author of the new study, led the development of the mandrel-free fabrication technique.

“High-spring-index yarns can be made much less expensively by this mandrel-free method,” Zhang said. “When heated and cooled, these muscles can significantly contract and elongate due to their large spring index.”

One application for the technology is comfort-adjusting jackets that automatically open large thermally insulating pores as the ambient temperature becomes uncomfortably cold.

Baughman and his team previously licensed their polymer artificial muscles made using a mandrel-wrapped process to a clothing manufacturer that incorporated the technology into jackets worn by members of the U.S. team at the 2022 Winter Olympics in Beijing. Because the mandrel-wrapped process was so expensive, however, the jackets are no longer commercially produced, Baughman said.

“Our new mandrel-free method for making high-spring-index coiled fiber avoids this major problem, so it may soon enable the commercialization of new comfort-adjusting jackets,” Baughman said.

Zhang said the fabrication method also enables the spring index to be varied along a muscle’s length. In addition, the researchers used the mandrel-free method to make high-spring-index carbon nanotube yarns, which could be used to harvest mechanical energy or as self-powered strain sensors.

The precise expansion and contraction strokes of the muscles are driven by heat, which is provided by applying electricity or by the use of solvents or electrochemical means.

The mandrel-free fabrication process involves inserting twist into individual fibers at a level below the twist causing them to coil back on themselves, then plying the twisted fibers to create springlike coils. During plying, each fiber serves as a mandrel for other fibers.