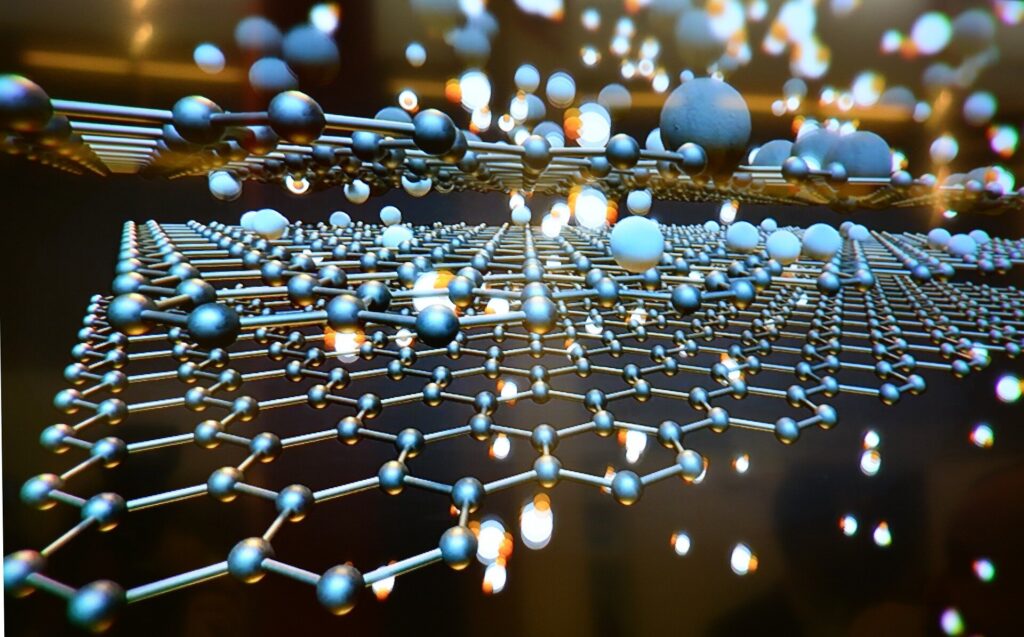

Since the groundbreaking discovery of graphene in 2004, the dizzying pace of progress in two-dimensional (2D) materials has ushered in a new era of fundamental research and technological innovation. Although nearly 2,000 2D materials have been theoretically predicted and hundreds have been created in laboratory settings, most of these 2D materials are limited to van der Waals (vdW) layered crystals.

Scientists have long been keen to develop atomically thin 2D metals, thereby expanding the 2D material family beyond vdW layered structures. These ultrathin 2D metals would also enable the exploration of novel physics and new device architectures. Over the past few years, many attempts have been made to realize 2D metals, but these attempts have failed to achieve large-size, pristine 2D metals at the atomically thin limit.

Now, however, researchers from the Institute of Physics (IOP) of the Chinese Academy of Sciences have developed a convenient, universal, atomic-level manufacturing technique—called vdW squeezing—for the production of 2D metals at the angstrom thickness limit. This study was recently published in Nature.

The manufacturing technique involves melting and squeezing pure metals between two rigid vdW anvils under high pressure. With this method, the researchers produced diverse atomically thin 2D metals, including Bi (~6.3 Å), Sn (~5.8 Å), Pb (~7.5 Å), In (~8.4 Å) and Ga (~9.2 Å).

The vdW anvils consist of two single-crystalline MoS2 monolayers epitaxially grown on sapphire. The anvils are essential for producing 2D metals for two reasons. First, the atomically flat, dangling-bond-free surface of the monolayer MoS2/sapphire ensures uniform 2D metal thickness over a large scale. Second, the high Young’s modulus of both sapphire and monolayer MoS2 (> 300 GPa) allows them to withstand extreme pressures, enabling 2D metals formed between the two anvils to approach their angstrom thickness limit.

The 2D metals synthesized via this process were stabilized through complete encapsulation between two MoS2 monolayers, making them environmentally stable and ensuring non-bonded interfaces. This structure facilitated device fabrication by allowing access to their intrinsic transport properties, which were previously unavailable.

Electrical and spectroscopic measurements of monolayer Bi revealed excellent physical properties, including significantly enhanced electrical conductivity, a strong field effect with p-type behavior, large nonlinear Hall conductivity, and new phonon modes.

This vdW squeezing, atomic-level manufacturing method not only offers a versatile approach to realizing various 2D metals but can also control the thickness of 2D metals with atomic precision (i.e., monolayer, bilayer, or trilayer) by controlling the squeezing pressure. This method offers extraordinary opportunities for revealing the exotic layer-dependent properties of 2D metals—something that was not possible before.

Prof. Zhang Guangyu from IOP, corresponding author of the study, said that the vdW squeezing technique offers an effective atomic-level method for manufacturing 2D metal alloys, as well as amorphous and other 2D non-vdW compounds. He also noted that this method outlines a “bright vision” for a broad range of emerging quantum, electronic, and photonic devices. He emphasized that there is “plenty of room” for this new research field to grow in the future.