As fruits and vegetables are perishable, it can be challenging to keep them fresh and safe to eat. In the time it takes to transport them from farm to table, these difficulties with post-harvest storage mean that enormous amounts of fresh produce are currently being wasted. While this waste can be reduced with the help of cold storage and robust packaging, these solutions are often highly unsustainable. They involve non-biodegradable plastics, or harmful chemicals which can leach into food and soil damaging the environment and even our own health.

In a new study published in Hybrid Advances, researchers led by Poornima Vijayan at Sree Narayana College for Women, Kollam, Kerala, India, present a promising new approach to protecting fresh produce.

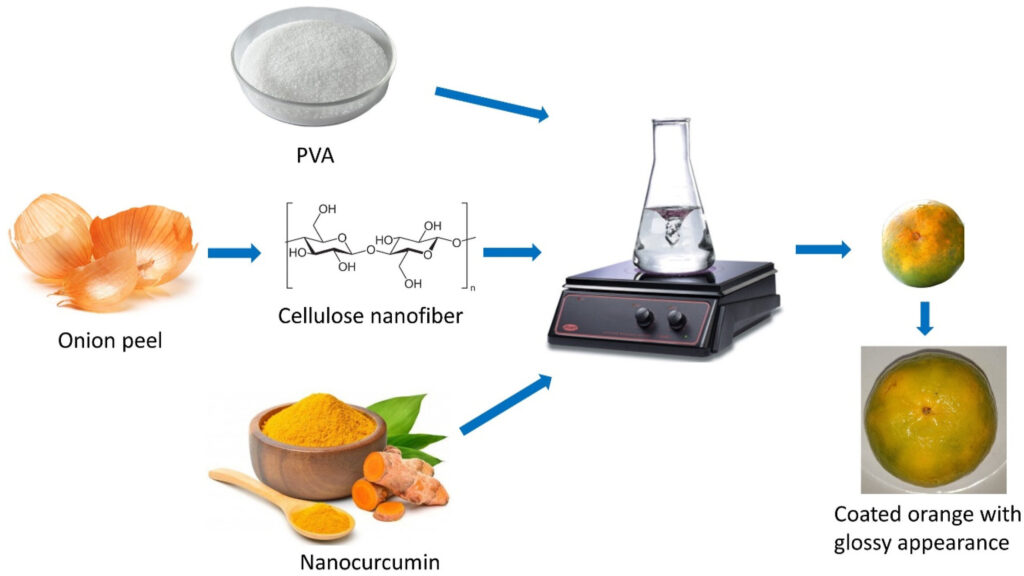

It involves coating fruits and vegetables with cellulose nanofibers extracted from onion skin, using a synthetic biopolymer to hold the fibers together, and nanocurcumin as an additional antimicrobial nanoparticle. The coating is not only completely edible; it can also extend the shelf-life of fruits and vegetables, while minimizing environmental impacts.

Three ingredients

Cellulose nanofibers (CNFs) are cellulose-based nanoscale fibers, produced from the primary structural component of plant cell walls. Recently, CNF-based coatings have been studied for their potential use as protective coatings for fresh produce. So far, however, this progress has been held back by their poor water resistance and thermal stability. This makes them vulnerable to degrading, especially in hot, humid regions such as India.

In their study, Vijayan’s team addressed this challenge through a new recipe for CNF-based coatings, which they tested on Mandarin oranges.

“To target cost-effective waste management in agriculture, we prepared the nanofibers from discarded onion peel,” Vijayan explains. “We coated the oranges with formulations of cellulose nanofibers, polyvinyl alcohol (PVA), and nanocurcumin.”

PVA is a synthetic polymer which is both non-toxic and biodegradable, as well as being tasteless and odorless. By mixing CNFs into this polymer matrix, the team could ensure that the nanofibers held firmly together, making the film more water and heat resistant. The addition of nanocurcumin added an extra level of protection: this material, which is extracted from turmeric powder, is well known for its anti-microbial and anti-fungal properties.

Protection against decay

To test their film’s performance, Vijayan’s team thoroughly mixed the three ingredients together, then dipped the oranges into the mixture for two minutes, before allowing them to air dry. Over the next two weeks, they then monitored changes to a variety of properties in the fruits including their weight, acidity, and total soluble solid (TSS), which is a measure of the concentration of sugars, proteins, and other complex molecules which break down as a fruit decays.

Compared with a set of unprotected oranges, the film kept the fruits fresh and safe to eat for far longer. While the unprotected fruits visibly started to decay within 13 days, the researchers observed that the film-coated oranges were far more pristine and displayed far smaller changes in weight, acidity, and TSS.

Based on this success, Vijayan’s team are now confident that their film may eventually transform our existing approaches to storing fresh fruits and vegetables.

“This research highlights the ‘wealth from waste’ concept: an effective conversion of agriculture waste [here, onion peel] into value-added products,” says Vijayan. “We present a sustainable solution for avoiding a growth in plastic pollution and lowering the health risks associated with microplastics from food packaging materials.”