The University of Liverpool has reported a significant advancement in engineering biology and clean energy. A team of researchers has developed an innovative light-driven hybrid nanoreactor that merges natural efficiency with cutting-edge synthetic precision to produce hydrogen—a clean and sustainable energy source.

The study, published in ACS Catalysis, demonstrates a pioneering approach to artificial photocatalysis, addressing a critical challenge in using solar energy for fuel production. While nature’s photosynthetic systems have evolved for optimal sunlight utilization, artificial systems have struggled to achieve comparable performance.

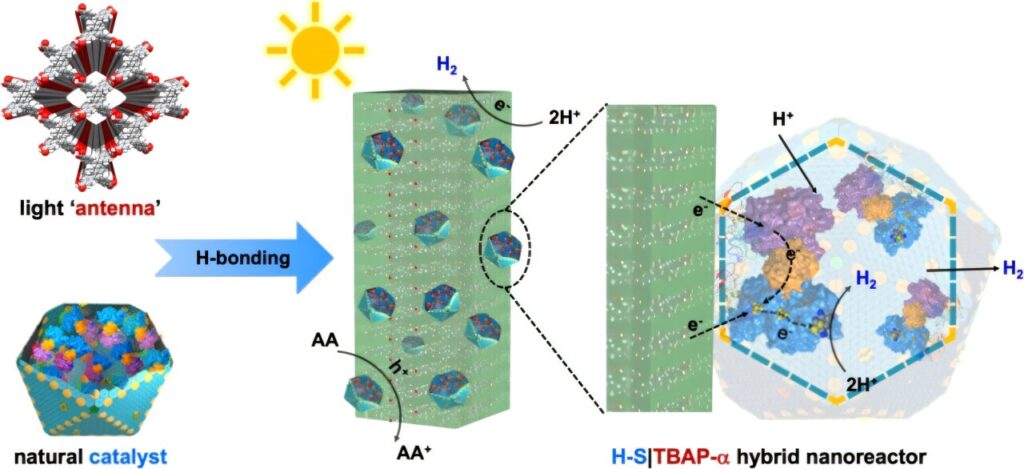

The hybrid nanoreactor is the product of a novel integration of biological and synthetic materials. It combines recombinant α-carboxysome shells—natural microcompartments from bacteria—with a microporous organic semiconductor. These carboxysome shells protect sensitive hydrogenase enzymes, which are highly effective at producing hydrogen but prone to deactivation by oxygen. Encapsulating these enzymes ensures sustained activity and efficiency.

Professor Luning Liu, chair of microbial bioenergetics and bioengineering at the University of Liverpool has worked in collaboration with Professor Andy Cooper, from the Department of Chemistry and Director of the University’s Materials Innovation Factory. Together, their teams synthesized a microporous organic semiconductor that acts as a light-harvesting antenna. This semiconductor absorbs visible light and transfers the resulting excitons to the biocatalyst, driving hydrogen production.

Professor Luning Liu said, “By mimicking the intricate structures and functions of natural photosynthesis, we’ve created a hybrid nanoreactor that combines the broad light absorption and exciton generation efficiency of synthetic materials with the catalytic power of biological enzymes. This synergy enables the production of hydrogen using light as the sole energy source.”

This latest work has significant implications and has the potential to eliminate the reliance on expensive precious metals like platinum—offering a cost-effective alternative to traditional synthetic photocatalysts while achieving comparable efficiency. This breakthrough not only paves the way for sustainable hydrogen production but also holds potential for broader biotechnological applications.

Professor Andy Cooper, director of the Materials Innovation Factory concluded, “It’s been fantastic to collaborate across university faculties to deliver these results. The study’s exciting findings open doors to fabricating biomimetic nanoreactors with wide-ranging applications in clean energy and enzymatic engineering, contributing to a carbon-neutral future.”