A recent study has aimed to create hydrophobic paper by exploiting the mechanical properties and water resistance of cellulose nanofibers, and so produce a sustainable, high-performance material suitable for packaging and biomedical devices. This involved a supramolecular approach, i.e., combining short chains of proteins (peptide sequences) that do not chemically modify the cellulose nanofibers. Sustainable hydrophobic paper may one day replace petroleum-related products.

The study is titled “Nanocellulose-short peptide self-assembly for improved mechanical strength and barrier performance,” and was featured on the cover of the Journal of Materials Chemistry B. The work was carried out by researchers from the “Giulio Natta” Department of Chemistry, Materials and Chemical Engineering at the Politecnico di Milano, in collaboration with Aalto University, the VTT-Technical Research Centre in Finland and the SCITEC Institute of the CNR.

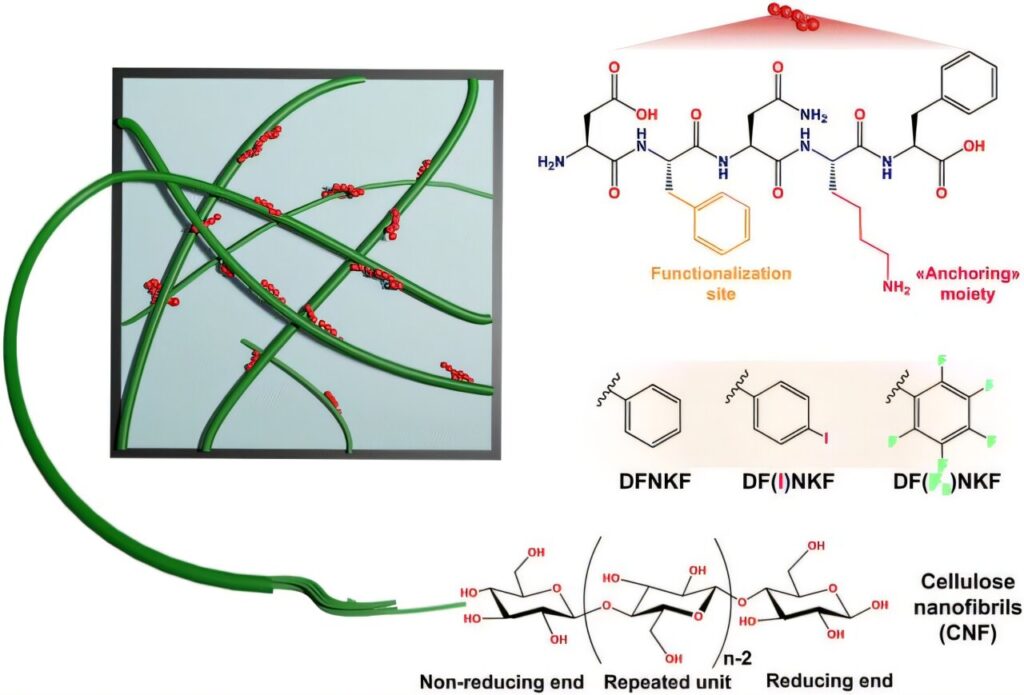

Cellulose nanofibers (CNFs) are natural fibers derived from cellulose—a renewable and biodegradable source—and are well known for their strength and versatility. In the study, the researchers from the SupraBioNanoLab of the “Giulio Natta” Department of the Politecnico di Milano showed how it is possible to greatly improve the properties of cellulose nanofibers without chemically modifying them, instead adding small proteins known as peptides.

“Our supramolecular approach involved adding small sequences of peptides, which bind onto the nanofibers and so improve their mechanical performance and water-resistance,” said Elisa Marelli, co-author of the study, explaining the methodology. “The results of the study showed that even minimal quantities of peptides (less than 0.1%) can significantly increase the mechanical properties of the hybrid materials produced, giving them greater resistance to stress.”

Finally, the researchers assessed the impact of adding fluorine atoms to the peptide sequences. This made it possible to create a structured hydrophobic film on the material, providing even greater water resistance while still preserving its biocompatible and sustainable characteristics.

As Pierangelo Metrangolo, co-author of the study, pointed out, “This advance opens up new opportunities for creating biomaterials that can compete with petroleum-derived materials in terms of performance, achieving the same quality and efficiency while reducing environmental impact. These hybrid materials are very suitable for sustainable packaging, where resistance to moisture is vital, and also for use in biomedical devices, thanks to their biocompatibility.”